Tempered glass powder coating booth

5 month ago

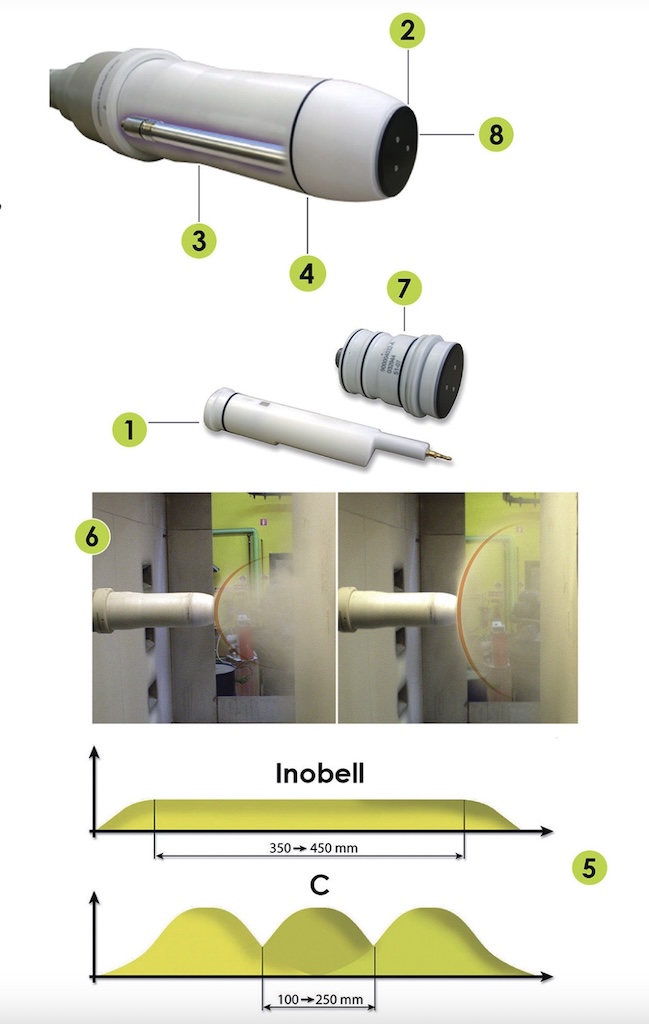

Inobell Powder Bell Sprayer

In order to meet the needs of saving powder and improving spraying effect, Sames has designed and developed the Inobell electrostatic powder spraying rotary cup, which achieves high performance, excellent spraying quality, and is easy to integrate. It can spray powder coating on all types of surfaces, with better performance on flat surfaces.

The Inobell electrostatic powder rotary cup originated from the spraying technology used in liquid coatings in the automotive industry. Its difference from traditional spraying equipment lies in its excellent spraying quality and smoothness. Compared with traditional round or flat nozzles, the centrifugal force generated by rotation makes the powder spray more uniform and less directional. Therefore, mechanical effects are limited, and powder particles are more susceptible to electrostatic forces, thereby improving transmission efficiency.

Rotating electrodes ensure excellent electrostatic charge at powder flow rates of up to 30 kg/h, while ensuring high transfer efficiency. Powder centrifugation can achieve uniform film thickness, thereby controlling the standard deviation (Ecat type) to save powder deposited on the workpiece.

Inobell technology uses rotating electrodes associated with reverse electrodes, allowing for maximum powder charge. It performs better when used on larger flat surfaces and can also be installed on flat reciprocating machines.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zhongshan Joihey Co., Ltd

- *Message:

-

Submit

Main Product:

Powder coating booth,

Powder spray booth,

Automatic powder coating line,

Vertical powder coating line,

Powder coating line ,

Automatic powder coating booth

You May Also Like