e3181888a6ba6a38ab3e4e0babd55f9d

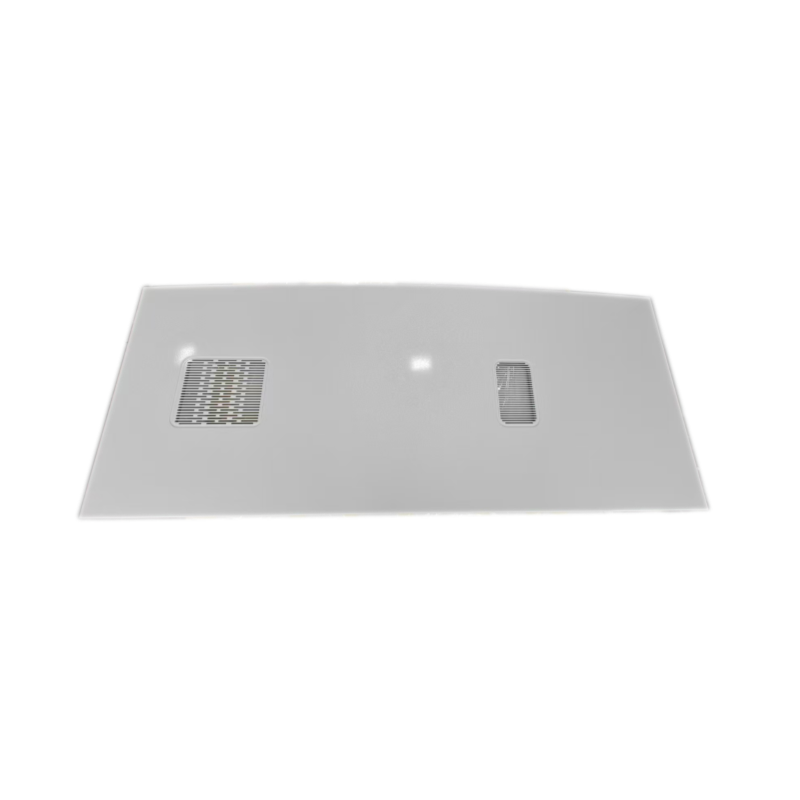

3 month agoIntroducing our premium line of vacuum-formed plastic shells specifically engineered for medical devices, designed to meet the highest industry standards. Our product range features an array of advanced attributes that cater to the diverse needs of healthcare professionals worldwide. Whether you're in need of a protective shield for delicate instruments or a transparent casing to monitor internal states, we provide solutions that blend functionality with precision engineering.

Our vacuum-formed medical device enclosures are crafted to offer unparalleled transparency, ensuring seamless visibility into the inner workings of your tools. These enclosures serve as robust barriers against environmental contaminants while offering customizable designs tailored to fit specific medical apparatuses. With user-friendly tearable or score-line features, accessing contents has never been easier. Additionally, certain models are equipped with sterilization compatibility, allowing them to endure rigorous high-pressure steam or ethylene oxide treatments. As a comprehensive provider of plastic parts for medical applications, we collaborate with leading brands like Philips, Siemens, Neusoft, Nuctech, and Sino-Vision, delivering top-tier quality and reliability.

Key Attributes:

Our vacuum-formed shells boast a series of standout features including superior clarity for real-time monitoring, protective mechanisms to shield against external threats, and flexibility in design customization. The enclosures are engineered with practical opening mechanisms, ensuring ease of access for end-users. Furthermore, they support various sterilization methods, providing peace of mind during critical operations. Beyond vacuum forming, our expertise extends to rotational molding, CNC machining, and mold creation, offering a holistic approach to manufacturing medical-grade plastics.

Detailing the Process:

Each vacuum-formed plastic shell undergoes meticulous processing using advanced techniques such as thermoforming and CNC cutting. We utilize high-quality materials including ABS, PMMA, PE, PVC, PP, PS, and PC, each selected for its unique properties that align with medical requirements. Our aluminum molds ensure durability and precision, with a tooling lifetime of up to 30,000 cycles. Customizable surface finishes ranging from smooth to textured are available, along with options for precise cut-to-size configurations. Adhering to stringent certifications such as ISO9001/14001/45001/IATF16949, we maintain the highest quality standards. The minimum order quantity starts at 100 pieces, with flexible packaging solutions tailored to your specifications.

Application Scenarios:

These versatile enclosures find application across numerous medical environments, from surgical theaters to diagnostic labs. They serve as protective casings for delicate instruments, ensuring their integrity during storage and transport. Transparent models allow healthcare providers to effortlessly assess the status of enclosed devices without compromising sterility. In research facilities, these enclosures act as reliable safeguards for experimental setups, minimizing risks of contamination. Their adaptability makes them ideal for both portable and stationary medical equipment.

User Reviews:

Healthcare professionals consistently praise our enclosures for their durability and ease of use. "The transparency is excellent," notes Dr. Emily Chen, a practicing surgeon. "It allows me to quickly check the condition of my tools without removing them from their protective casing." Another user, Mr. Robert Thompson, highlights the convenience of the tearable feature, stating, "Opening these enclosures is straightforward and efficient, saving valuable time during busy shifts."

Frequently Asked Questions:

What types of sterilization methods are supported? Our enclosures are compatible with both high-pressure steam and ethylene oxide gas sterilization processes, ensuring they remain sterile post-cleaning. How durable are these enclosures? Constructed from premium materials and reinforced through advanced vacuum-forming techniques, they offer long-lasting protection against wear and tear. Are custom designs possible? Absolutely! We specialize in creating bespoke enclosures tailored to specific medical device dimensions and requirements. What certifications do you hold? We adhere to ISO9001/14001/45001/IATF16949 standards, ensuring compliance with global quality benchmarks.

PRODUCTS DISPLAY

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Wuxi Suyi Science & Technology Co., Ltd.

- *Message:

-

Submit

Main Product:

vacuum forming,

various plastic components,

rotational molding,

thermoforming,

CNC machining ,

mold making

You May Also Like