General features of bag-feeding packaging machines

Highly automated and intelligent

Adopting PLC control system and touch screen human-machine interface, it is easy to operate and supports flexible adjustment of parameters, such as packaging speed, bag length, etc.

With automatic detection function, if the bag is not opened or the filling is abnormal, the operation will be suspended to avoid material waste

Supports a variety of feeding methods (such as weighing, screw metering, filling machine, etc.), to meet the precise filling needs of different materials

Efficient energy saving and environmental protection

Frequency conversion speed regulation technology can adjust the speed according to production needs and reduce energy consumption

Oil-free vacuum pump and food-grade materials (such as stainless steel 304) design to avoid environmental pollution and meet food hygiene standards

Wide applicability

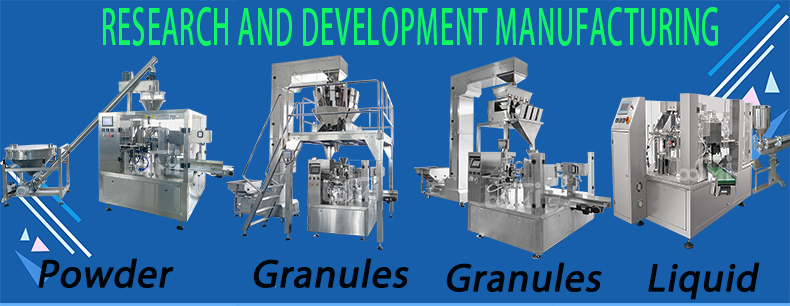

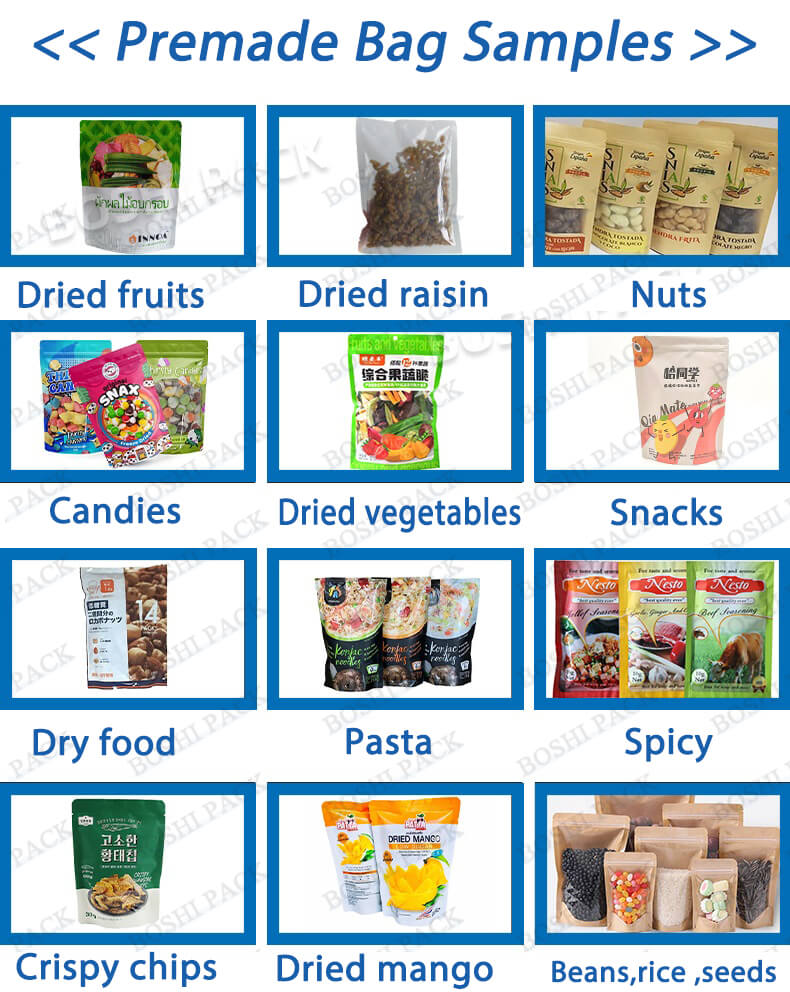

Can handle liquid, powder, granular, block and other forms of materials, applicable industries cover food, daily chemicals, medicine, etc.

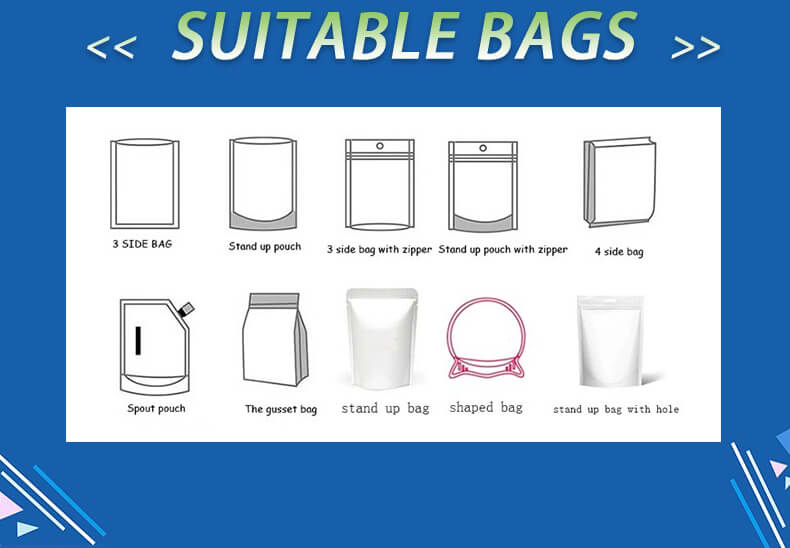

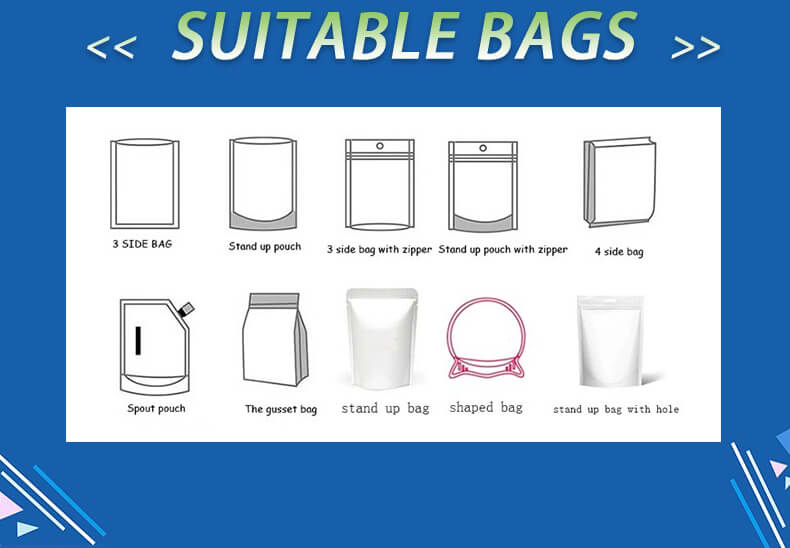

Compatible with a variety of packaging materials, such as composite film, aluminum foil, PE, etc., and supports three-side sealing, four-side sealing and other different bag types

Suitable for 3 side seal bag, 4 side seal bag, handing hole bag, paper bag, stand up bag, zipper bag , doypack bag, M bag ,etc.

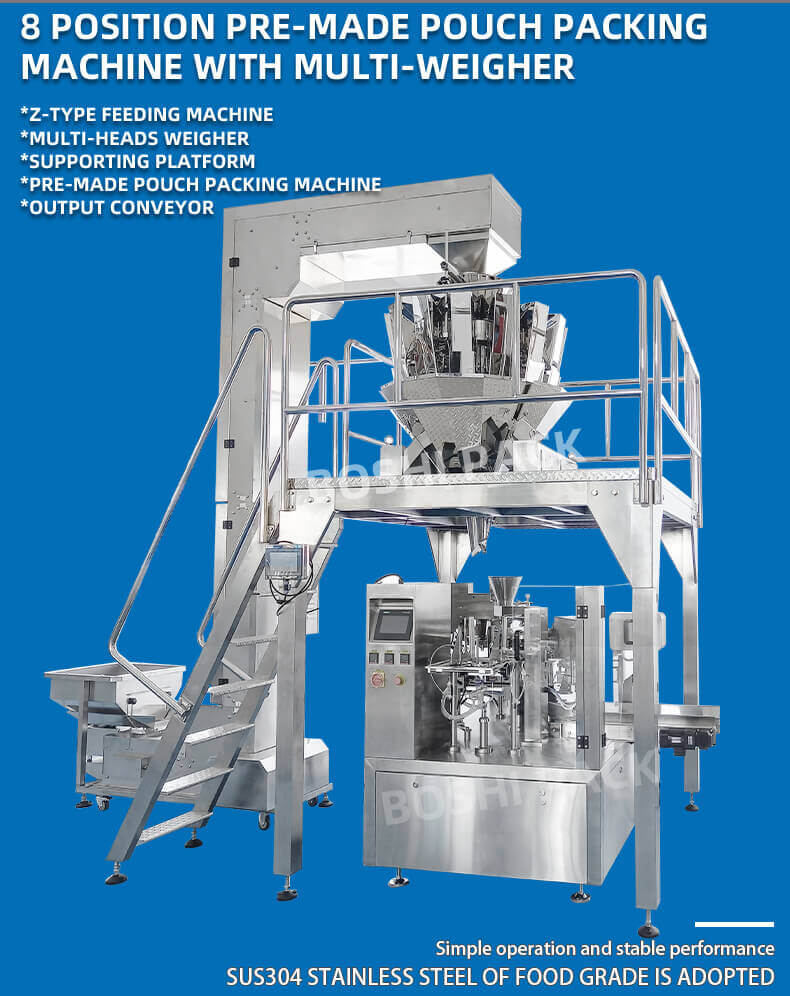

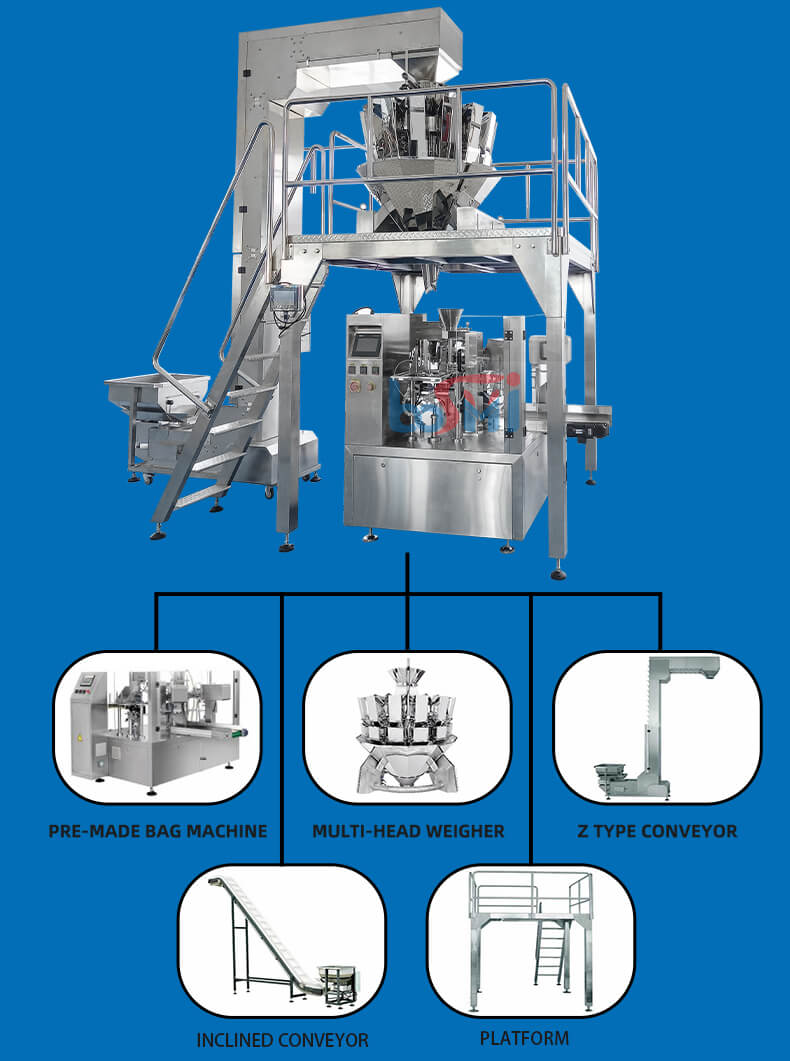

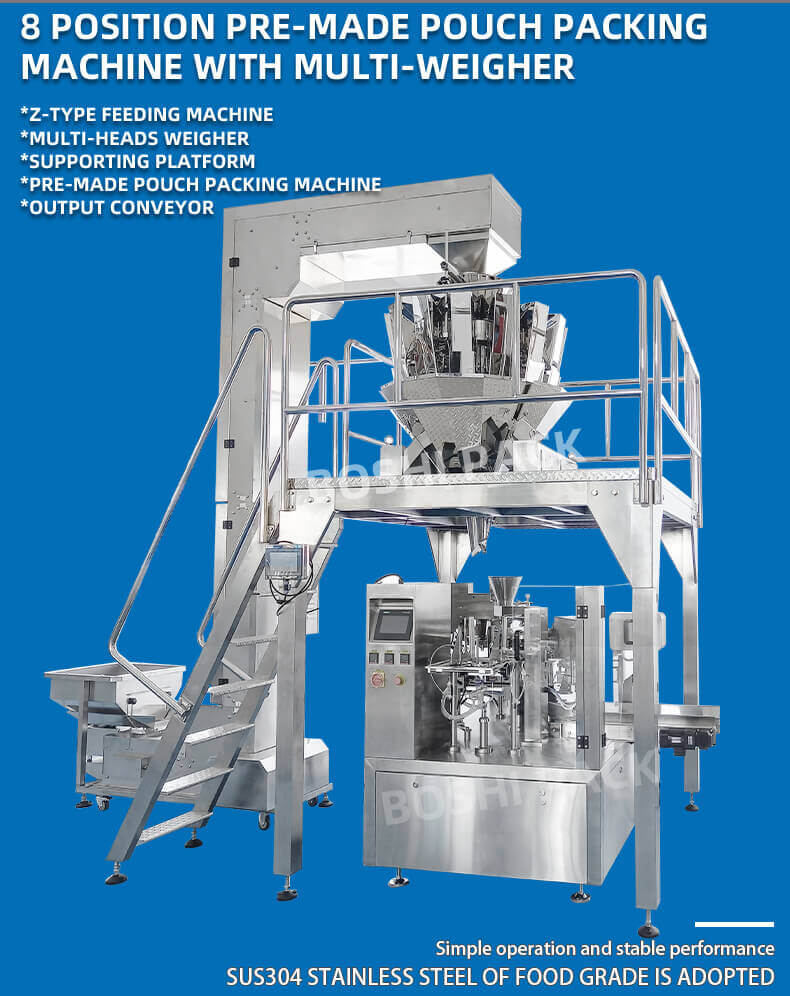

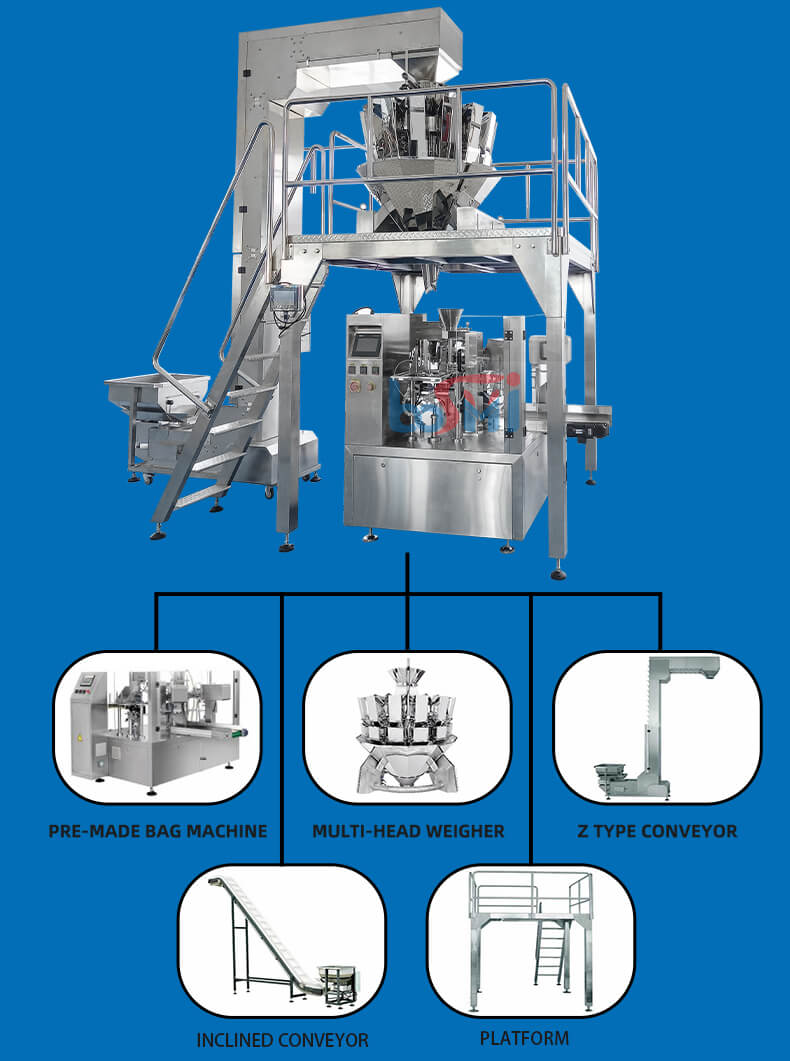

Premade Bag Doypack Packing Machine Details :

* The pre-made bag packing machine can auto load, pick up bag, open bag, weigh, flll, seal, and output.

*Pre-made bag packing machine is a trend of automatic production, which directly replaces manual, can achieve packing automation, largely improving production efficiency and greatly reducing costs.

* Contact parts use stainless steel which meet food hygiene requirements.

*Realize electricity -mechanical integr ation.With smart touch screen, Stable cam mechanical transmission technology makes machine stable, low failure rate and low energy consumption.

* Machine can auto detect and feedback. If no bag or bag didn't open during the production process, Machine will stop filling and sealing, then alarm. So it will not waste your film or product, ensure your workshop is clean.

* It can use many films,suitable for single-layer PE, PE composite film, CPP composite film, aluminum film, composite pre-made bag, paper bag, etc.

* Machine use pre-made bags, which can reduce the loss of film, beautiful bag shape,good sealing, improved product grade, So it becoming more and more popular in the world.

* Changed different size bag quickly, putting bag device's size can be easily adjusted, saves manpower and time.