Characteristics of PP Double-Color Film and Its Applications in Disposable Cutlery Blister Packaging

3 week ago

Polypropylene (PP) double-color film has emerged as a standout material in the realm of packaging, particularly for disposable cutlery blister packaging. This innovative film, crafted from polypropylene resin, combines functionality with aesthetic appeal, making it an ideal choice for industries seeking sustainable yet practical solutions. In this article, we will delve into the defining characteristics of PP double-color film and explore its specific applications in blister packaging for disposable cutlery, highlighting its advantages, technical merits, and real-world utility.

Characteristics of PP Double-Color Film

PP double-color film is produced through a sophisticated process involving the extrusion of polypropylene resin, blended with color masterbatches, toughening agents, and brighteners. The mixture undergoes plasticizing extrusion, three-roll calendering, cooling, traction, and winding to create a robust yet flexible film. This manufacturing process imparts the film with a unique set of properties that distinguish it from other packaging materials like PVC or PET.

- Non-Toxic and Hygienic: One of the most compelling features of PP double-color film is its non-toxic nature. Unlike some alternatives that may release harmful substances when incinerated, PP film is free of halogens and other hazardous compounds. This makes it a safe choice for food-contact applications, such as disposable cutlery packaging, where hygiene is paramount. Its odorless quality further enhances its suitability for sensitive products.

- Mechanical Strength and Durability: The film boasts impressive mechanical strength, allowing it to withstand the rigors of handling, transportation, and storage. Its high tensile strength ensures that blister packs made from PP double-color film maintain their integrity, protecting the contents from damage. This durability is particularly beneficial for cutlery items like forks, spoons, and knives, which require sturdy packaging to prevent bending or breaking.

- Excellent Barrier Properties: PP double-color film offers good barrier protection against moisture, oxygen, and light—key factors in preserving the quality of packaged goods. While its water vapor transmission rate (WVTR) is not as low as some high-barrier materials like PCTFE, it rivals PVDC-coated PVC, making it effective for short- to medium-term storage of disposable cutlery. This barrier capability ensures that the cutlery remains clean and free from environmental contaminants.

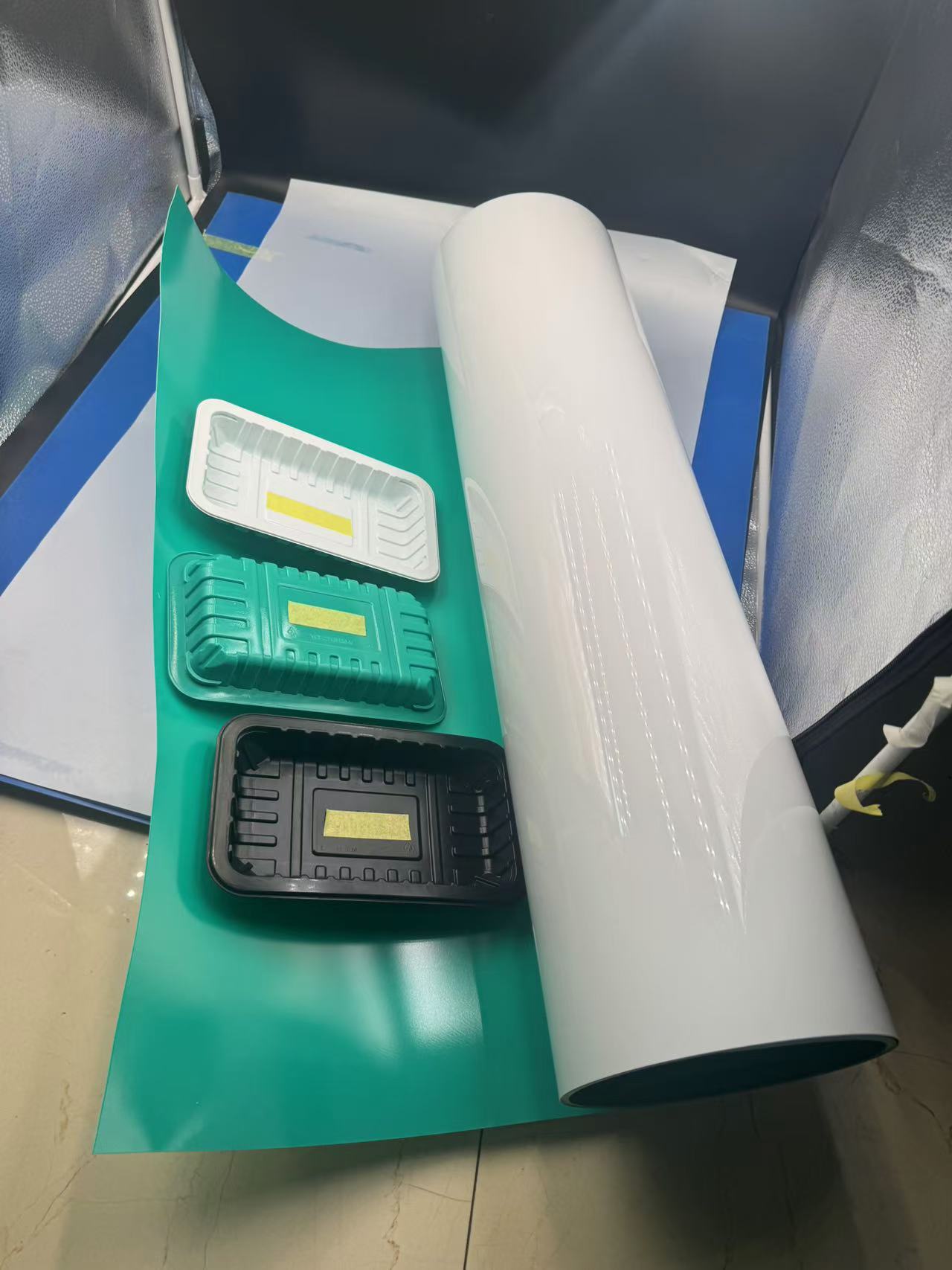

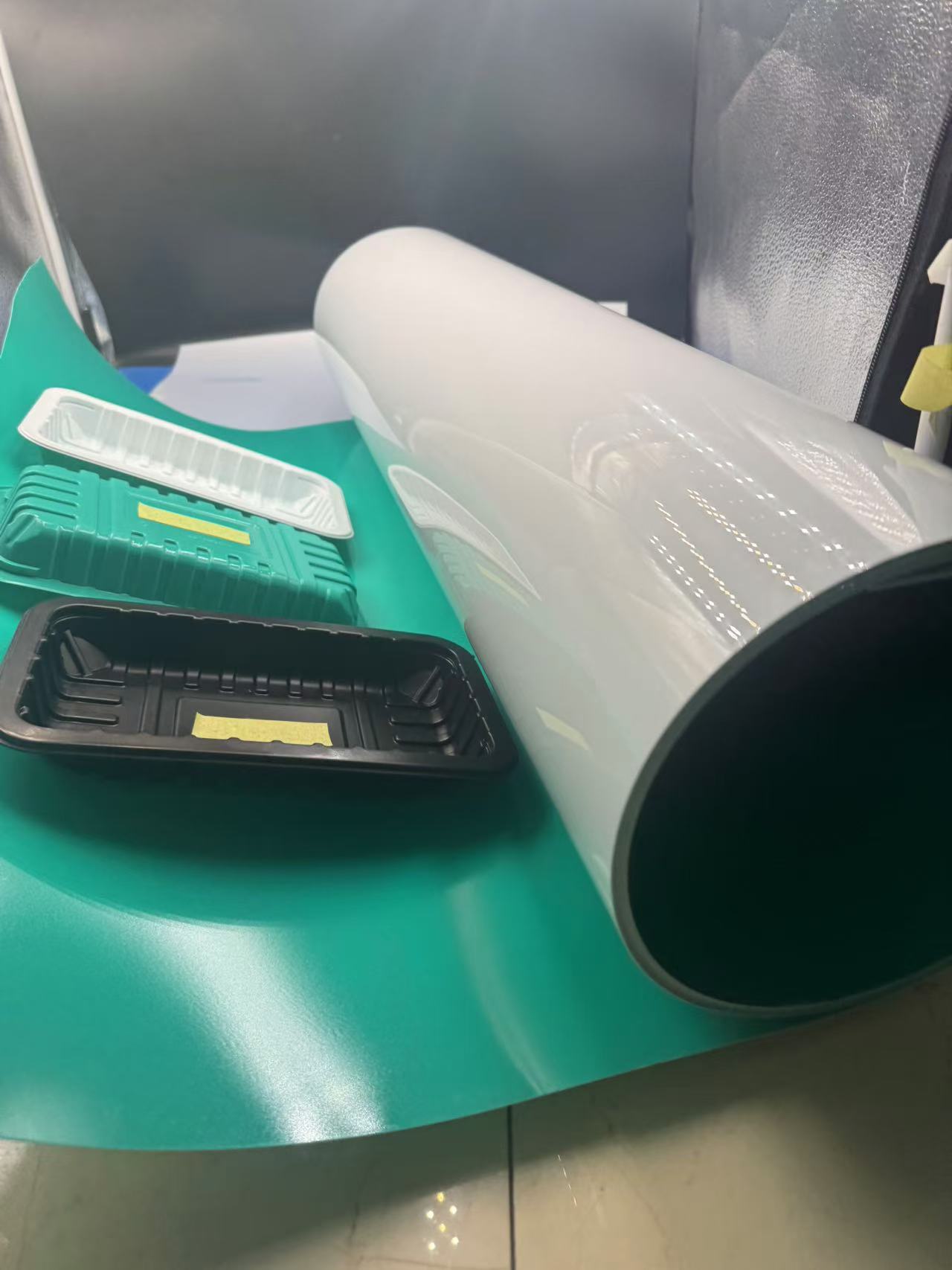

- Aesthetic Appeal with Double-Color Design: The double-color feature of this film sets it apart visually. By incorporating two distinct color layers, manufacturers can create eye-catching designs that enhance product visibility on retail shelves. For instance, a transparent top layer paired with a vibrant base color can showcase the cutlery while adding a premium look, appealing to consumers who value both form and function.

- Thermoformability and Processability: PP double-color film excels in thermoforming, a critical process in blister packaging. When heated to temperatures between 160°C and 220°C, the film becomes pliable, allowing it to be molded into precise cavities that snugly fit cutlery items. Its molding shrinkage, typically ranging from 1.0% to 2.5%, ensures dimensional stability, while its heat deflection temperature (80°C–100°C) supports consistent performance during forming.

- Lightweight and Cost-Effective: With a density of 0.91–0.95 g/cm³, PP double-color film is lighter than many competing materials, such as PVC (1.38 g/cm³). This reduced weight translates to lower shipping costs and less material usage per unit, offering economic advantages to manufacturers. Additionally, its recyclability aligns with growing sustainability demands, reducing environmental impact compared to less eco-friendly options.

- Chemical Resistance and Toughness: The film’s excellent chemical resistance protects it from degradation when exposed to oils, cleaning agents, or other substances commonly encountered in foodservice environments. Its toughness and high bending fatigue life further ensure that blister packs remain intact even under repeated flexing or stress.

Applications in Disposable Cutlery Blister Packaging

Disposable cutlery—spoons, forks, knives, and stirrers—requires packaging that balances protection, presentation, and practicality. PP double-color film meets these needs through its unique properties, making it a preferred material in blister packaging applications. Let’s explore how it is applied and why it excels in this context.

- Secure Product Encapsulation: In blister packaging, the film is thermoformed into cavities tailored to the shape of each cutlery piece. For example, a spoon’s curved bowl and handle can be precisely accommodated by a molded pocket, ensuring a snug fit that prevents movement during transit. The film’s mechanical strength reinforces this encapsulation, safeguarding the cutlery from external pressures that might otherwise cause cracking or deformation.

- Enhanced Visual Appeal: The double-color design plays a pivotal role in retail settings. Imagine a blister pack where the top layer of PP film is transparent, revealing a set of sleek white plastic forks against a contrasting blue or green base layer. This combination not only highlights the product but also creates a striking visual effect that draws consumer attention. Such aesthetics are crucial for disposable cutlery sold in supermarkets, convenience stores, or airline meal kits, where branding and presentation influence purchasing decisions.

- Hygienic Protection for Single-Use Items: Disposable cutlery must remain sterile until use, especially in foodservice applications like takeout meals or hospital catering. PP double-color film’s barrier properties protect against moisture and dust, ensuring that each piece remains uncontaminated. For instance, a fast-food chain packaging plastic spoons for soup can rely on this film to maintain hygiene standards, reassuring customers of product safety.

- Ease of Use and Accessibility: Blister packs made from PP double-color film often feature a push-through design, where the cutlery can be easily extracted by pressing it through a lidding material (typically aluminum foil or a compatible PP-based lid). The film’s toughness ensures that the blister retains its shape during this process, while its flexibility allows for smooth separation without tearing excessively. This user-friendly feature is ideal for on-the-go consumers who need quick access to

utensils.

- Sustainability in Disposable Packaging: As environmental concerns grow, the recyclability of PP double-color film offers a significant advantage. Unlike PVC, which releases hydrochloric acid when burned, PP incinerates cleanly and can be mechanically recycled into new products. For disposable cutlery packaging, this aligns with the push toward circular economy practices, appealing to eco-conscious brands and consumers alike. A study by Recipharm noted that PP-based blister packaging has an 86% lower global warming impact than traditional aluminum-PVC alternatives, underscoring its green credentials.

Real-World Examples and Technical Insights

Consider a practical scenario: a manufacturer producing blister packs for a set of biodegradable plastic knives for a picnic kit. Using PP double-color film with a thickness of 0.5 mm, they thermoform cavities at 180°C, achieving a uniform wall thickness and a shrinkage rate of 1.5%. The resulting pack features a clear top layer and a forest-green base, enhancing the natural theme of the product while ensuring durability during shipping. The knives, secured within the blisters, remain intact even after a bumpy journey, thanks to the film’s high bending fatigue life.

From a technical perspective, the film’s WVTR of approximately 0.20 g/m²/day (comparable to PVDC-coated PVC) ensures that moisture-sensitive biodegradable materials stay dry, extending shelf life. Its heat deflection temperature of 90°C also means the pack can withstand warm storage conditions without warping—a common issue with lower-grade films.

In another instance, a catering company opts for PP double-color film to package single-use forks for a large event. The film’s lightweight nature reduces logistics costs, while its double-color design (transparent over black) elevates the perceived quality of the budget-friendly cutlery. The thermoforming process, optimized with modern blister machines that compensate for PP’s shrinkage, ensures high-speed production without compromising precision.

Challenges and Solutions

Despite its advantages, PP double-color film faces processing challenges. Its narrow thermoforming temperature range requires precise control to avoid warping or uneven stretching. Modern equipment, like Körber blister machines with extended preheating stations, addresses this by evenly distributing heat, enhancing process stability. Additionally, while PP’s barrier properties are robust, they fall short of cold-form foils for highly sensitive products. For disposable cutlery, however, this is rarely a concern, as the focus is on short-term protection rather than long-term preservation.

Conclusion

PP double-color film represents a fusion of practicality, aesthetics, and sustainability in disposable cutlery blister packaging. Its non-toxic composition, mechanical strength, and barrier properties ensure product safety and integrity, while its double-color design elevates visual appeal. From securing knives in a picnic kit to presenting forks for a catering event, this film adapts seamlessly to diverse needs. As industries prioritize eco-friendly solutions, PP double-color film stands out as a versatile, cost-effective, and forward-thinking choice, proving that packaging can be both functional and beautiful

.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film ,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products

You May Also Like