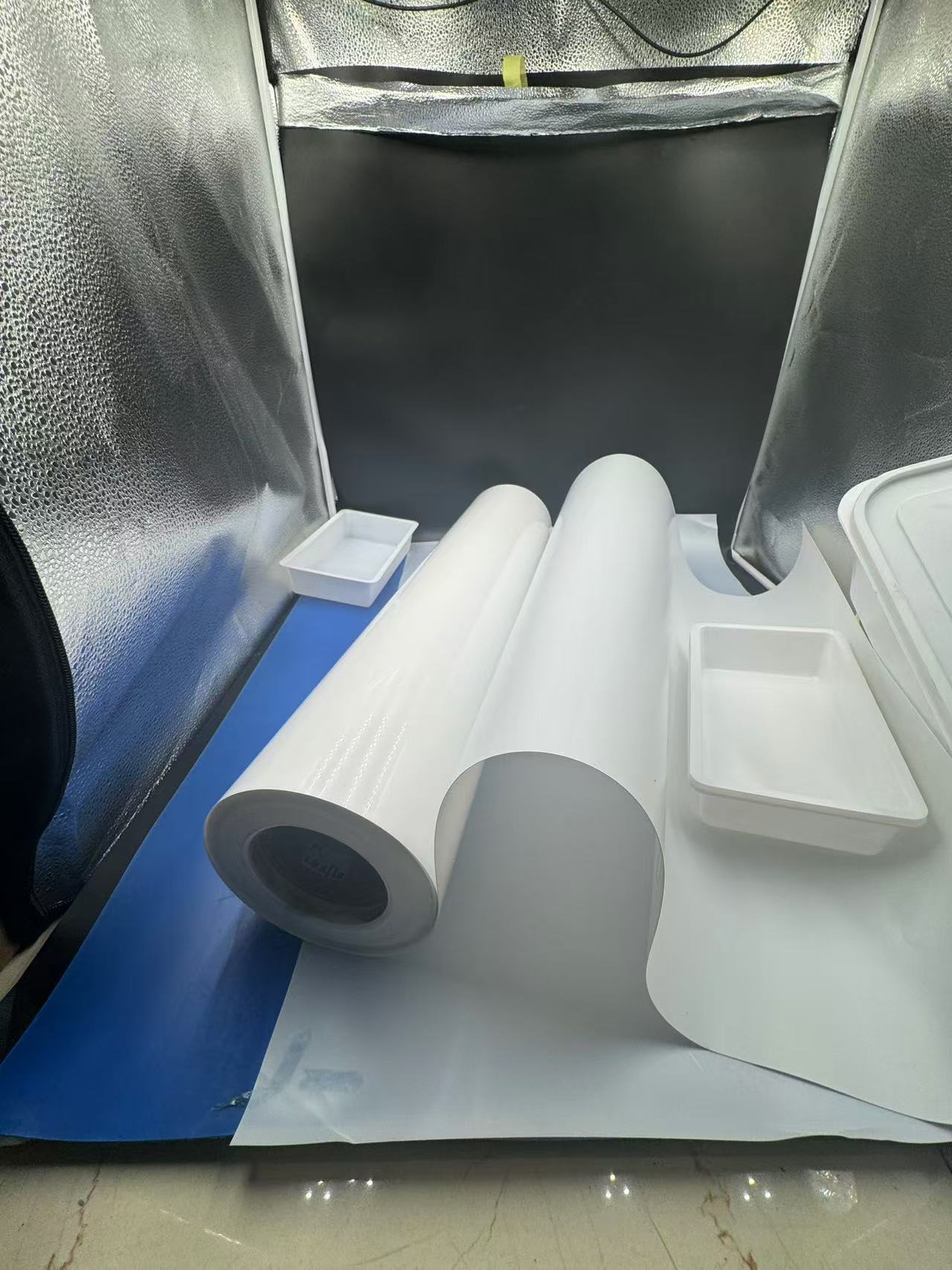

Unveiling the Versatility of White PS Film in Modern Food Solutions

3 week agoPolystyrene (PS) film, particularly in its white variant, has emerged as a cornerstone material in the realm of food packaging and disposable tableware. Known for its adaptability, cost-effectiveness, and functional properties, white PS film plays a pivotal role in meeting the demands of modern food industries. This article delves into the intrinsic characteristics of white PS film and explores its widespread use in thermoforming packaging and disposable tableware, offering a detailed, evidence-based perspective on why it remains a preferred choice despite evolving market trends and environmental considerations.

Characteristics of White PS Film

White PS film, derived from polystyrene—a synthetic polymer made from styrene monomers—exhibits a unique combination of physical and chemical properties that make it highly suitable for food-related applications. Let’s break down its key characteristics:

- Rigidity and Strength: White PS film is inherently rigid, providing structural integrity to packaging and tableware. While pure polystyrene (often referred to as general-purpose polystyrene or GPPS) can be brittle, the white variant used in food applications is typically modified with additives or copolymers, such as butadiene, to enhance its toughness. This modification results in high-impact polystyrene (HIPS), which balances rigidity with improved resistance to cracking, making it ideal for items that need to withstand handling without shattering.

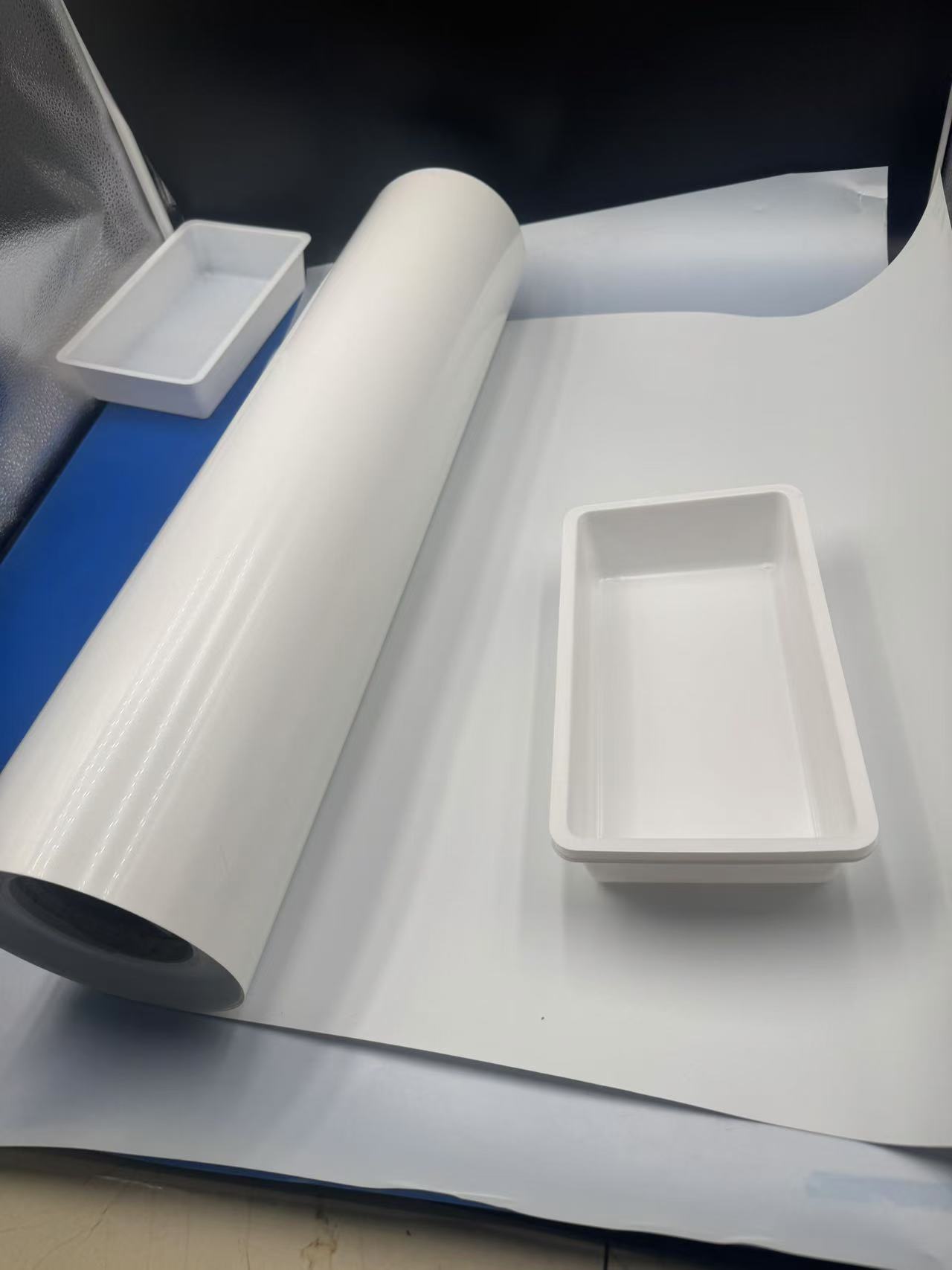

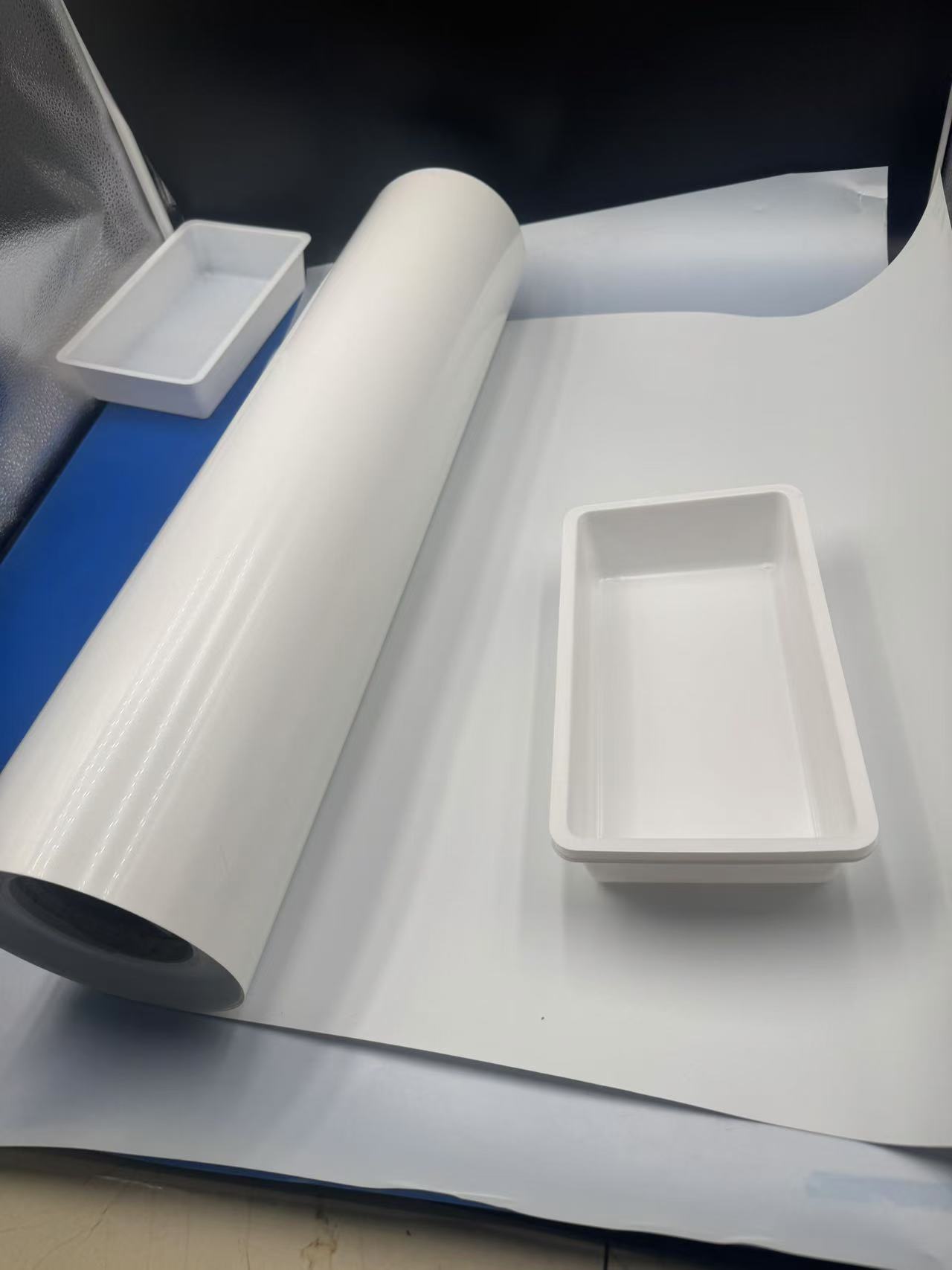

- Opacity and Aesthetic Appeal: Unlike transparent PS film, the white version offers an opaque finish, achieved through the incorporation of pigments like titanium dioxide. This opacity not only enhances visual appeal—giving products a clean, professional look—but also provides a degree of light protection, which can be beneficial for light-sensitive foods. The smooth, glossy surface of white PS film further elevates its aesthetic value, making it a popular choice for branded packaging and tableware.

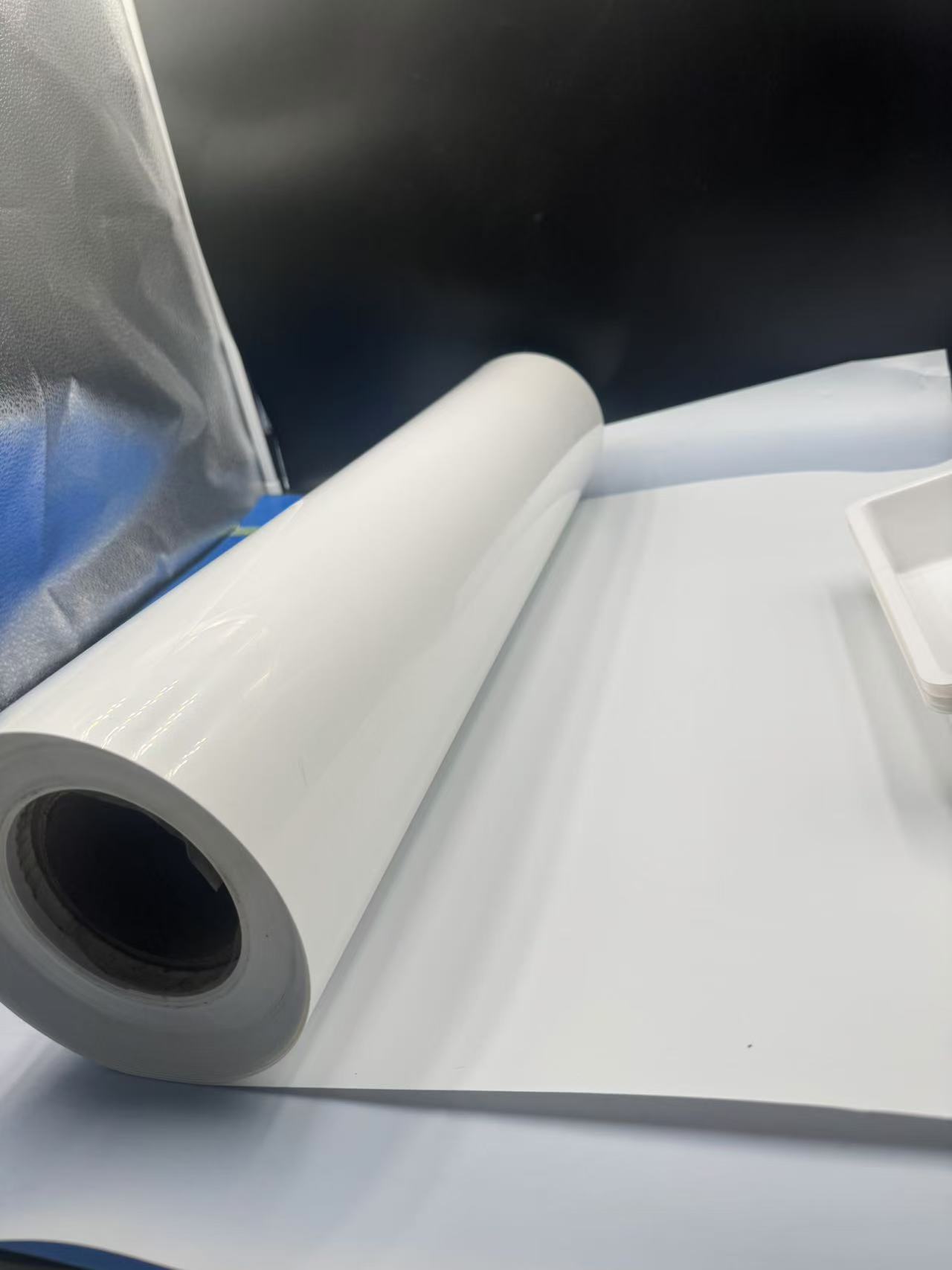

- Thermoformability: One of the standout features of white PS film is its excellent thermoforming capability. When heated to its glass transition temperature (around 100°C), the film becomes pliable, allowing it to be molded into intricate shapes using vacuum or pressure-forming techniques. This property is critical for creating precise, custom-fit packaging trays and tableware designs, such as clamshells, plates, and cups, with minimal material waste.

- Lightweight Nature: White PS film is remarkably lightweight, a trait stemming from its low density (approximately 1.05 g/cm³). This characteristic reduces shipping costs and makes it convenient for single-use applications, aligning with the fast-paced needs of the foodservice industry.

- Cost-Effectiveness: Polystyrene is relatively inexpensive to produce compared to alternatives like polyethylene terephthalate (PET) or polypropylene (PP). The affordability of white PS film makes it an attractive option for manufacturers aiming to keep production costs low while delivering functional, high-quality products.

- Moisture and Chemical Resistance: While white PS film is not as robust a barrier to gases as some other plastics, it offers adequate resistance to moisture and certain chemicals, such as acids and bases. This makes it suitable for short-shelf-life food items, like takeout meals or bakery goods, where prolonged exposure to air isn’t a primary concern.

- Thermal Insulation: In its foamed form (expanded polystyrene or EPS), white PS film provides excellent thermal insulation, keeping hot foods warm and cold foods chilled. Even in its solid form, it retains some insulating properties, which is advantageous for disposable tableware used in quick-service settings.

Despite these strengths, white PS film has limitations. It softens at relatively low temperatures (above 100°C), rendering it unsuitable for high-heat applications like microwaveable containers unless specially treated. Additionally, its brittleness in unmodified forms and poor recyclability in some regions pose challenges, which we’ll address later.

Applications in Food Thermoforming Packaging

Thermoforming, a process where plastic sheets are heated and shaped into molds, is a dominant application for white PS film in food packaging. Its versatility shines in this context, enabling the creation of a wide array of packaging solutions tailored to specific food types. Here’s how white PS film excels in this domain:

- Trays and Clamshells: White PS film is widely used to produce thermoformed trays for meats, poultry, fish, and bakery items. Its rigidity ensures that these trays maintain their shape under the weight of the product, while the white color provides a clean backdrop that highlights the food’s freshness. For example, a butcher might use a white PS film tray to package ground beef, where the film’s slight flexibility (thanks to HIPS modifications) prevents cracking during transport, and its opacity masks any minor discoloration of the meat.

- Dairy Packaging: In the dairy sector, white PS film is a staple for yogurt cups and cheese containers. The film’s ability to be scored and snapped—owing to its inherent rigidity—makes it perfect for multi-pack yogurt designs, where consumers can easily separate individual portions. The smooth surface also supports high-quality printing, allowing brands to display vibrant logos and nutritional information, enhancing shelf appeal.

- Fast Food Containers: Takeout containers, such as those for sandwiches or salads, often rely on white PS film due to its lightweight nature and cost efficiency. A typical fast-food clamshell made from white PS film might feature a hinged lid, formed seamlessly during thermoforming, offering convenience for both the vendor and the consumer. The material’s insulation properties help maintain food temperature during short delivery windows, a critical factor in customer satisfaction.

- Bakery and Deli Displays: White PS film trays are a go-to for bakery goods like cookies and pastries, as well as deli items like sliced meats and cheeses. The film’s glossy finish and white hue create an inviting presentation, while its strength protects delicate items from being crushed. For instance, a tray of croissants packaged in white PS film retains its shape on a supermarket shelf, ensuring the product looks as good as it tastes.

The thermoforming process itself underscores the material’s practicality. Manufacturers heat white PS film rolls to a pliable state, then use molds to shape them into trays or containers, often integrating features like stacking ridges or snap-fit lids. This efficiency, combined with the material’s low cost, allows for high-volume production runs that meet the demands of large-scale food distributors.

Applications in Disposable Tableware

Beyond packaging, white PS film is a key player in the production of disposable tableware, catering to the needs of restaurants, catering services, and households. Its properties translate seamlessly into practical, single-use items:

- Plates and Bowls: White PS film is thermoformed into plates and bowls that offer a sturdy, lightweight alternative to paper or heavier plastics. A picnic organizer, for example, might choose white PS film plates for their durability during outdoor use—capable of holding a hearty serving of pasta salad without buckling—while their bright white finish gives a premium feel compared to flimsy paper alternatives.

- Cups and Lids: Disposable cups made from white PS film are common in coffee shops and fast-food outlets. The material’s ability to be foamed into EPS enhances insulation, keeping beverages hot or cold, while solid PS film lids provide a secure seal. Picture a bustling café handing out lattes in white PS film cups: the lightweight design reduces strain on staff, and the insulation ensures the drink stays warm for the customer’s commute.

- Cutlery: Forks, spoons, and knives crafted from white PS film offer a balance of rigidity and slight flexibility, making them functional for single-use scenarios. While not as durable as reusable plastic cutlery, they suffice for casual dining—like a food truck serving tacos—where convenience trumps longevity. The white color adds a touch of elegance, elevating the dining experience beyond basic clear or black options.

- Serving Trays: Catering events often feature white PS film serving trays, which are thermoformed to include compartments for different foods. Their strength supports heavier items like sliced fruits or sandwiches, and the white surface provides a neutral, appetizing backdrop. A wedding caterer might use these trays to present hors d’oeuvres, appreciating their disposability after a long night of service.

The production of these items leverages white PS film’s thermoformability, allowing manufacturers to create complex shapes with minimal material. For instance, a bowl’s curved edges or a cup’s ribbed texture—designed for grip—are easily achieved, enhancing both utility and user experience.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film ,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products

You May Also Like