Diaphragm filter presses

3 year agowhat is Diaphragm filter presses?

Diaphragm Filter Press Is A Type Of Filter Press That Uses A Diaphragm To Separate The Liquid From The Solid Particles. The Diaphragm Is A Flexible Membrane That Is Placed Between The Filter Plates And The Filter Cloth. The Diaphragm Is Made Of Rubber Or Polypropylene And Is Designed To Allow Liquid To Pass Through While Preventing Solid Particles From Passing. This Type Of Filter Press Is Used In Various Industries Including Wastewater Treatment, Food And Beverage Processing, And Chemical Processing. Diaphragm Filter Presses Are Ideal For Applications Where A High Degree Of Solids Separation Is Required.

Filter Press Membrane Filter Press Sludge Dewatering Machine for Wastewater Treatment

Filter Press Introduction

Filter press consist of frame, filter plate, pressing system and electric control cabinet. Frame consist of base, push plate and girder and supports the pressing device and filter plate. Filter plates are installed on girder between tail plate and push plate, with filter cloth sandwiched in them. In operation, the pressing device drives the push plate to press the filter plates and filter cloth between push plate and tail plate. The function of electric control cabinet is to control the process of the sludge dewatering, such as set the dewatering time, the pump pressure, the treating capacity, and so on.

Filter Press Fabricate Process

China PLC Control Automatic Filter Press

Our company supply various series of filter presses, including chamber filter press, plate and frame filter press, stainless steel filter press, lab type filter press, automatic filter press, water washing filter press, cast iron filter press, vertical filter press, etc.

Introduction of Filter Press:

A filter press is a batch operation, fixed volume piece of equipment ranging from 0.1m3 -20m3 that separates liquids and solids using pressure filtration. Slurry is pumped into the filter press and dewatered under pressure. A filter press can be used for solid-liquid separation or wastewater treatment in a variety of different industries and applications, such as mining, metallurgy, petrol, chemical, medical, dyeing, paper, food, alcohol, textile production, etc..

Main components of filter press:

>> Frame: The steel frame acts as a clamping device for the filter plates.

>> Filter Plates: A filter cake forms in the chambers between filter plates.

>> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids..

Type of filter press according to:

>> Closing mode: manual, gear drive, hydraulic;

>> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

>> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

>> Filter plate material: PP, rubber, cast iron, stainless steel;

>> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500,2000

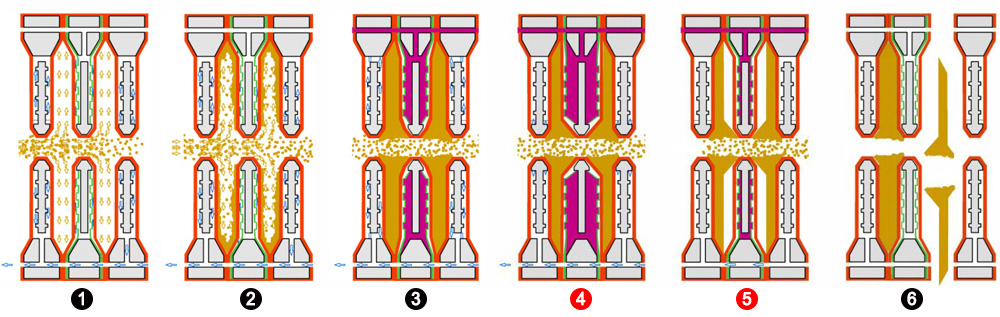

Working principle of China Automatic Filter Press:

- Feeding: Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- Filtration: Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- Filtration completed: When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- Membrane Squeezing: Once the chambers are full, the fill cycle is over, high pressure water or compressed air will start fill in between membranes of filter plates, pushing the membrane toward the filter cakes, squeezing the filter cakes to remove any residue water.

- Presssure relief: when squeezing is over, high pressure water(compressed air) is released from between the membranes.

- Cake discharge: after pressure relived, the filter press is ready to discharge cakes.

(* Note: 4, 5 is only for membrane filter press)

How to order your filter press:

- Firstly, please refer to technical data of filter press, choose a suitable model, plate material, plate closing mode, filtration flow mode.

- Based on production requirements, please choose between: open-flow, close-flow; cake washing, non-washing before ordering.

- Slurry feeding pump, squeezing pump(or air compressor) is not included in the filter press machine by default, please add them to your purchase order if they are requested from us.

- Customized filter press for special working conditions are available, please feel free to present your requirements.

- Due to upgrade of machines, all technical data are subject to change without prior nofications.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Hongfa Environmental Protection Equipment CO., LTD

- *Message:

-

Submit

Main Product:

Filter Press,

Plate and Frame Filter Press,

Chamber Filter Press,

Membrane Filter Press,

Wastewater Treatment ,

filter press pump

You May Also Like