cover plate 3

2 year ago

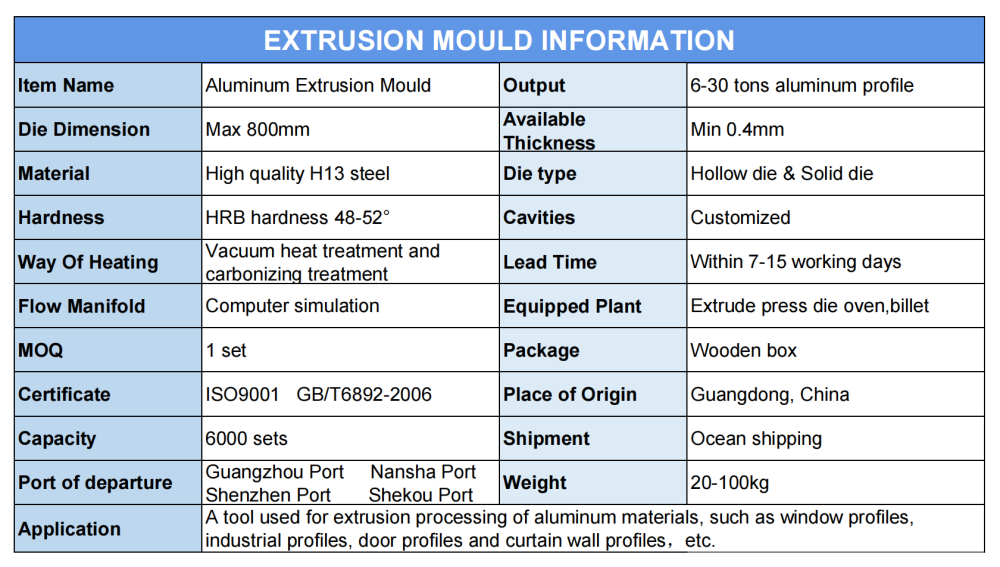

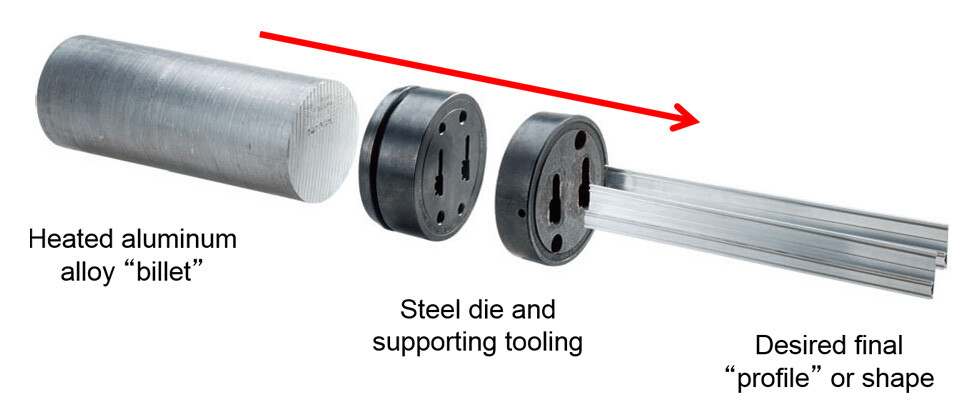

Aluminium Extrusion Working Principle:

During extrusion, under the strong extrusion force, the ingot is divided into several strands of metal by the knife (bridge part) of the mold and flows into the mold welding chamber. Under the conditions of high temperature, high pressure and high vacuum, the metal is re-welded and flows from the die hole to the needle. It flows out from the formed gap to form a hollow product of the required shape and size. The number of welds in the product is the same as the number of strands of metal flow.

The working principle of extruded aluminum profile mold mainly includes the following steps:

1. Preheating: First, preheat the aluminum profile and extrusion die to a certain temperature.

2. Extrusion: The preheated aluminum profile is put into the extruder and extruded through the cavity of the mold under high pressure to form the desired profile shape.

3. Cooling: The extruded aluminum profile needs to be cooled to fix its shape.

4. Cutting: The cooled aluminum profile is cut to the required length.

5. Heat treatment: In order to improve the hardness and strength of aluminum profiles, heat treatment is usually required.

6. Surface treatment: As needed, the surface of the aluminum profile may need to be frosted, anodized, electrophoretic painted, powder sprayed, etc.

In the whole process, the function of the extrusion die is to determine the shape of the extruded aluminum profile through the shape of its internal cavity during the extrusion process. The design and production of molds directly affect the quality and production efficiency of aluminum profiles.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

Wire Electrical Discharge Machining

It belongs to the category of electric processing.

When the couple of the former Soviet Union Lazalianke studied the phenomenon and cause of the damage of the switch contacts by spark discharge corrosion, they found that the instantaneous high temperature of the electric spark can make the local metal melt, oxidize and be corroded, thus creating And invented the electric discharge machining method.

The wire cutting machine was also invented in the former Soviet Union in 1960, and our country was the first country to use it in industrial production.

EDM wire cutting machine can be divided into reciprocating type:

High Speed Wire cut Electrical Discharge Machining

Low Speed one-way walk Wire cut Electrical Discharge Machining

Vertical Wire Electrical Discharge Machining machine tool With Rotation Wire.

It can also be divided into single column cross table type and double column type (commonly known as gantry type) according to the form of workbench.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like