door materials 8

2 year ago

Analysis of global aluminum product structure

There are certain differences in the global aluminum product structure between different regions and industries, but the following general analysis can be made:

Aluminum materials and semi-finished products: Aluminum materials and semi-finished products are the main components of the global aluminum product structure. This includes aluminum plates, aluminum coils, aluminum profiles, aluminum foil, etc. Aluminum materials and semi-finished products are widely used in construction, transportation, packaging, electricity and other fields, and are the main products of the aluminum industry.

Aluminum building materials: Aluminum building materials are an important part of the global aluminum product structure. Aluminum alloy doors and windows, aluminum curtain walls, etc. are widely used in the construction field. These products are lightweight, corrosion-resistant and durable, providing good architectural appearance and functionality.

Automotive industry: The automotive industry is one of the important areas of global aluminum product consumption. Aluminum alloy parts are widely used in automobile manufacturing, such as engine parts, body structures, wheels, etc. Aluminum's lightweight properties help improve fuel efficiency and reduce tailpipe emissions.

Packaging Industry: Aluminum packaging products have a wide range of applications worldwide. Aluminum cans, aluminum foil, etc. can be used for packaging of food, beverages, pharmaceuticals and other products. Aluminum packaging products have excellent moisture-proof, anti-oxidation and fresh-keeping properties, which can extend the shelf life of products.

Aerospace field: The aerospace field is an industry with a large demand for high-performance aluminum alloys. Aluminum alloys are used in aerospace for aircraft structures, engine parts, aerospace equipment, etc. High strength, light weight and corrosion resistance make aluminum alloys an ideal material choice.

Applications of aluminum alloys in the automotive industry

Aluminum alloys are widely used in the automobile industry and are mainly used in the manufacture of various parts of automobiles, including body, engine, suspension system, rims, etc. Here are some specific applications:

1. Body and frame: The lightweight properties of aluminum alloy make it widely used in the manufacture of body and frame. Using aluminum alloys can significantly reduce the overall weight of a car, thereby improving fuel efficiency and reducing emissions.

2.Engine parts: The high thermal conductivity and excellent corrosion resistance of aluminum alloys make it very popular in the manufacture of engine parts. For example, aluminum alloys can be used to make engine cylinder heads, pistons, and radiators.

4. Rim: The lightweight and beautiful appearance of aluminum alloy make it very popular in the manufacture of rims.

5. Other components: In addition to the above components, aluminum alloys are also used to manufacture other components of automobiles, such as fuel systems, braking systems, electrical systems, etc.

In general, the application of aluminum alloys in the automotive industry can improve the fuel efficiency, performance and durability of the vehicle, while also improving the aesthetics of the vehicle.

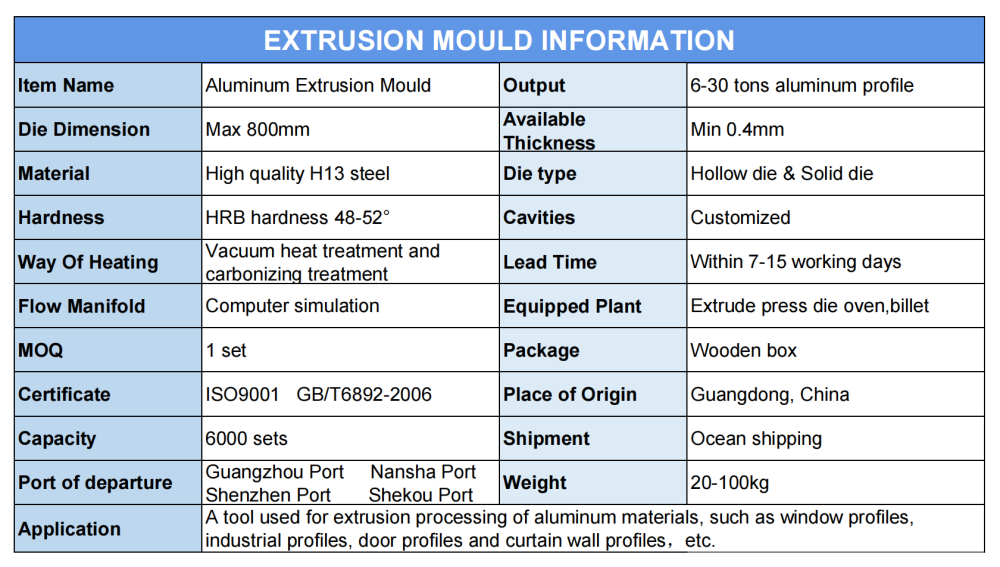

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

Computer Numerical Control

A CNC milling machine is a milling machine controlled by a digital signal of an electronic meter.

CNC milling machine is an automatic processing equipment developed on the basis of general milling machine. The processing technology of the two is basically the same, and the structure is somewhat similar.

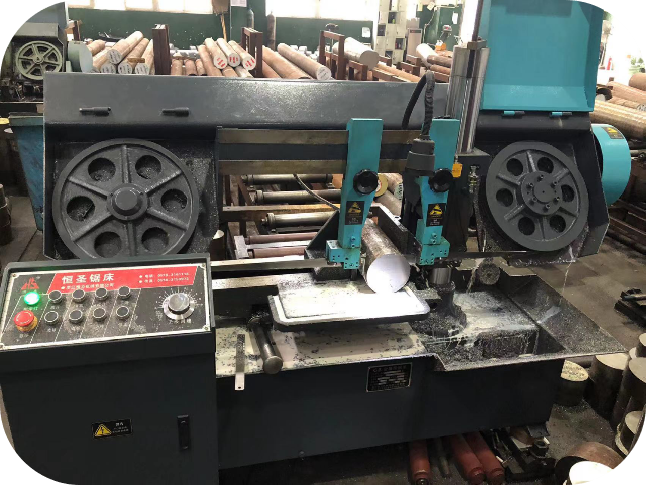

Saw Machine

The circular saw band is tensioned on two saw wheels, and the saw wheels drive the saw band to cut. There are two main types of band sawing machines: vertical and horizontal.

The saw frame of the vertical band sawing machine is set vertically, and the workpiece moves during cutting, which is used to cut the curved contour of the sheet and formed parts. The saw band can also be replaced with a file chain or abrasive belt for repairing or grinding.

The saw frame of the horizontal band sawing machine is arranged horizontally or obliquely, and is fed in the vertical direction or in the direction of swinging around a point. The saw band is generally twisted by 40° to keep the saw teeth perpendicular to the workpiece.

Horizontal type is divided into scissors type, double column, single column type band sawing machine; according to the use situation, it can be divided into manual type (economic type, manual feeding and manual cutting of materials), automatic type; according to the automation program using the controller, it can be divided into manual type ( Semi-automatic manual feeding) Fully automatic type (automatic feeding and automatic cutting).

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like