Non-thermal break frame

2 year ago

Analysis of the six major advantages of aluminum alloy door and window profiles:

As the eyes and soul of a building, doors and windows are directly related to the quality of the building and the quality of living life. It is not only a tool to protect from wind and rain, but also has the function of separating the inside of the home from the outside society. It also plays an important decorative role. What are the advantages of aluminum alloy door and window profiles?

1. Strong plasticity

Aluminum alloy profiles are metal materials. Aluminum is added with various metal elements to make various alloys. It has the unparalleled advantages of other alloy profiles: light weight and high strength, and can be extruded into various complex cross-section profiles to meet the design of doors and windows. The various new cross-section requirements of the division.

2. Good sealing performance

Aluminum alloy profiles have strong air tightness, water tightness, heat insulation and sound insulation. These properties are suitable for various specific applications in the door and window industry.

3. Long service life

Aluminum alloy profiles have the advantages of light weight, high strength, corrosion resistance, small deformation, strong fire resistance and long service life (more than 50 years).

4. Environmental protection and energy saving

The broken bridge aluminum alloy profile uses a new type of thermal insulation material nylon 66 to form a hot and cold bridge between the inner and outer profiles, thereby minimizing the heat conduction of the aluminum alloy and achieving excellent heat and sound insulation effects.

5. Excellent weather resistance

Aluminum alloy profiles have been treated with various processes, and the surface is resistant to acid and alkali erosion and is not affected by air pollution, acid rain, and ozone. UV resistant, retains inherent color and luster for a long time.

6. Elegant decorative effect

The surface of aluminum alloy profiles can be subjected to various surface treatments, such as powder spraying, anodizing, electrophoretic coating, wood grain transfer and other surface treatment technologies. There are a variety of colors and wood grains. There is a wide range of choices to meet various needs. It meets the needs of architectural decoration and puts beautiful clothes on the building.

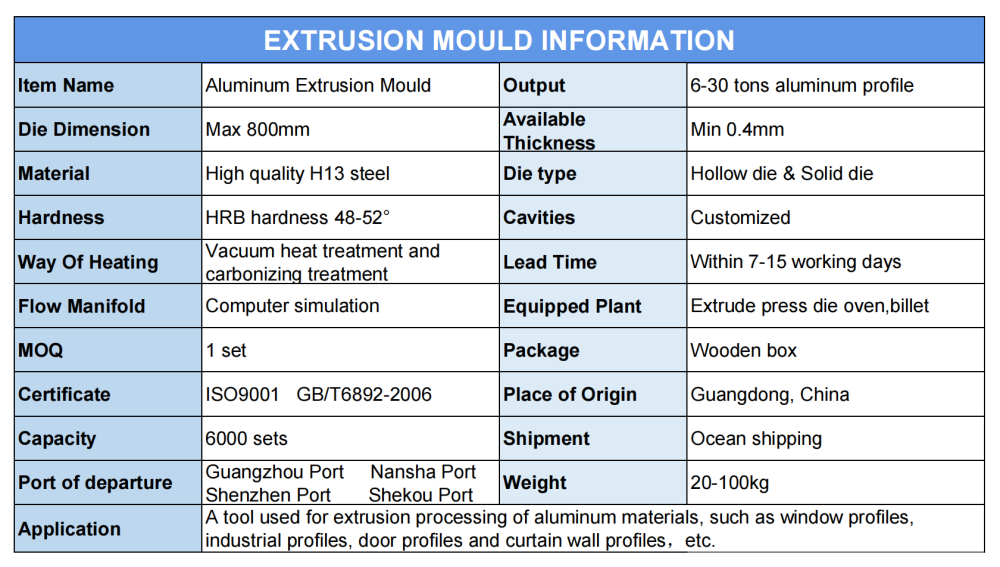

JIELIWEI has been providing aluminium profile mould for clients at home and abroad. With extraordinary craftsmanship and competitive price in this trade, more and more clients established long-term cooperative relationships with us.

If you are looking for Architectural Aluminum Profile Mold, Decorative Aluminum Profile Mold, Industrial Aluminum Profile Mold, Curtain Wall Aluminium Profile Extrusion Dies, Lighting Material Aluminium Profile Extrusion Dies, Roller Shutter Aluminium Profile Extrusion Dies..., Jieliwei is the perfect extrusion mold supplier for you!

Aluminum alloys are widely used in lighting, mainly in the following aspects:

1. Lamp body material: Aluminum alloy has good thermal conductivity and corrosion resistance, so it is often used as the main body material of lamps, which can effectively dissipate heat and extend the service life of lamps.

2. Reflector: Aluminum alloy has excellent reflective properties and is often used as a reflector for lamps, which can improve the efficiency of light and reduce energy consumption.

3. Radiator: Some high-power lamps, such as LED lamps, will generate a lot of heat. Aluminum alloy has good heat dissipation performance and can be used as a radiator for lamps to prevent the lamps from overheating and ensure their stable operation.

4. Lamp stand: Aluminum alloy has high strength and light weight. It can be used as a light stand for lamps to support the weight of the lamp. It can also reduce the weight of the lamp and facilitate installation and movement.

5. Decoration: The surface of aluminum alloy can be processed in a variety of ways, such as anodizing, electrophoretic coating, spraying, etc., which can change its color and gloss and improve the decorativeness of the lamp.

Therefore, aluminum alloys are widely used in lighting, which can not only improve the performance of lamps, but also improve their aesthetics.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

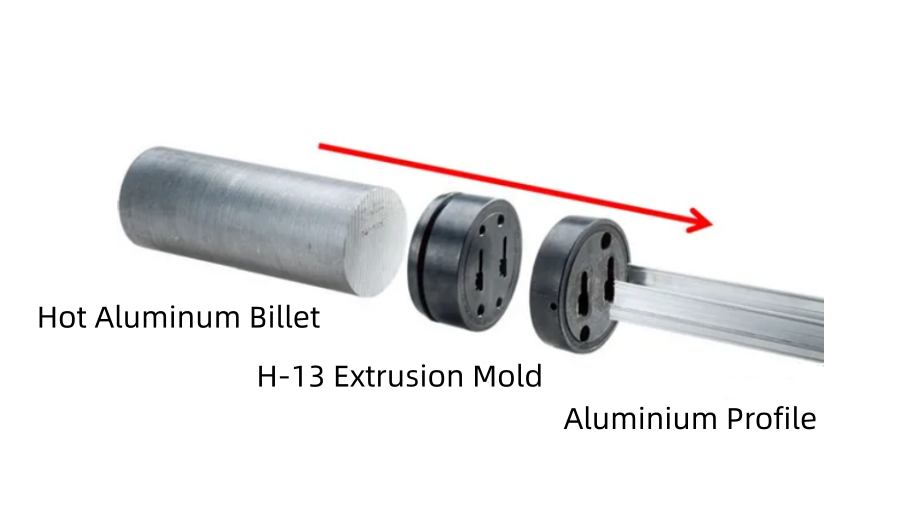

Aluminium Extrusion Working Principle:

During extrusion, under the strong extrusion force, the ingot is divided into several strands of metal by the knife (bridge part) of the mold and flows into the mold welding chamber. Under the conditions of high temperature, high pressure and high vacuum, the metal is re-welded and flows from the die hole to the needle. It flows out from the formed gap to form a hollow product of the required shape and size. The number of welds in the product is the same as the number of strands of metal flow.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like