Window materials 19

2 year ago

Advantages of aluminum alloy railings:

1. Corrosion resistance: Aluminum alloy railings will not rust due to moisture in the air or other acid and alkali substances, so their service life is much longer than ordinary iron railings.

2. Beautiful: Aluminum alloy railings have a high appearance finish and bright color, and the color can be freely selected, which can greatly improve the aesthetics of the building.

3. Easy maintenance: Aluminum alloy railings do not require frequent maintenance and repairs. They only need to be cleaned regularly to maintain their beauty.

4. Lightweight and high strength: Aluminum alloy railings are light in weight, but high in strength, not easily deformed, and have good safety performance.

5. Environmental protection: Aluminum alloy railings are a recyclable material and have little environmental pollution.

6. Easy installation: The installation of aluminum alloy railings is simple and quick, and does not require complex installation tools and techniques.

7. Reasonable price: Compared with railings made of other materials such as stainless steel and wood, aluminum alloy railings are more affordable and cost-effective.

Aluminium Extrusion Working Principle:

During extrusion, under the strong extrusion force, the ingot is divided into several strands of metal by the knife (bridge part) of the mold and flows into the mold welding chamber. Under the conditions of high temperature, high pressure and high vacuum, the metal is re-welded and flows from the die hole to the needle. It flows out from the formed gap to form a hollow product of the required shape and size. The number of welds in the product is the same as the number of strands of metal flow.

The working principle of extruded aluminum profile mold mainly includes the following steps:

1. Preheating: First, preheat the aluminum profile and extrusion die to a certain temperature.

2. Extrusion: The preheated aluminum profile is put into the extruder and extruded through the cavity of the mold under high pressure to form the desired profile shape.

3. Cooling: The extruded aluminum profile needs to be cooled to fix its shape.

4. Cutting: The cooled aluminum profile is cut to the required length.

5. Heat treatment: In order to improve the hardness and strength of aluminum profiles, heat treatment is usually required.

6. Surface treatment: As needed, the surface of the aluminum profile may need to be frosted, anodized, electrophoretic painted, powder sprayed, etc.

In the whole process, the function of the extrusion die is to determine the shape of the extruded aluminum profile through the shape of its internal cavity during the extrusion process. The design and production of molds directly affect the quality and production efficiency of aluminum profiles.

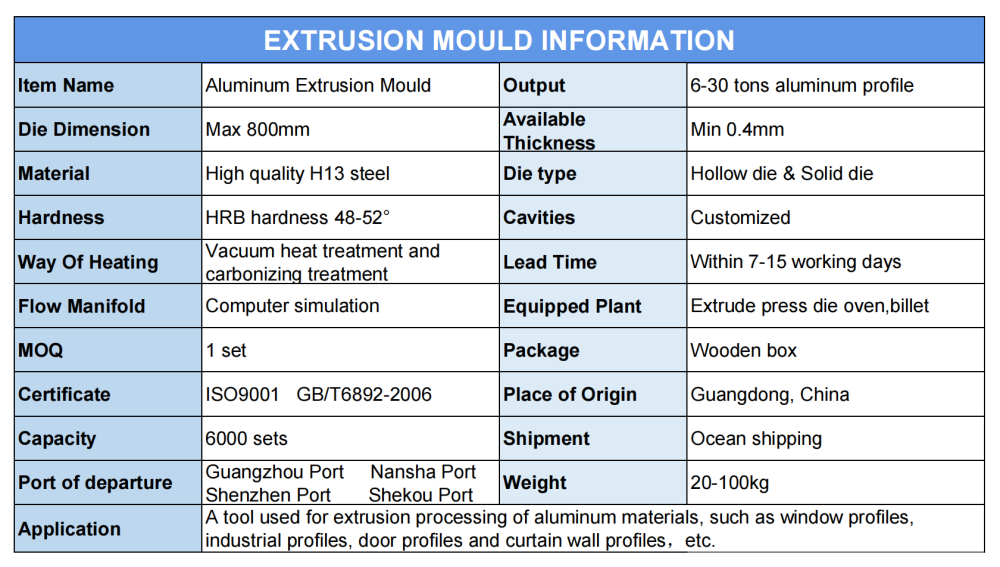

JIELIWEI has been providing aluminium profile mould for clients at home and abroad. With extraordinary craftsmanship and competitive price in this trade, more and more clients established long-term cooperative relationships with us.

If you are looking for Architectural Aluminum Profile Mold, Decorative Aluminum Profile Mold, Industrial Aluminum Profile Molds, Curtain Wall Aluminium Profile Extrusion Dies, Lighting Material Aluminium Profile Extrusion Dies, Roller Shutter Aluminium Profile Extrusion Dies..., Jieliwei is the perfect extrusion mold supplier for you!

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like