car base extrusion mold 2

2 year ago

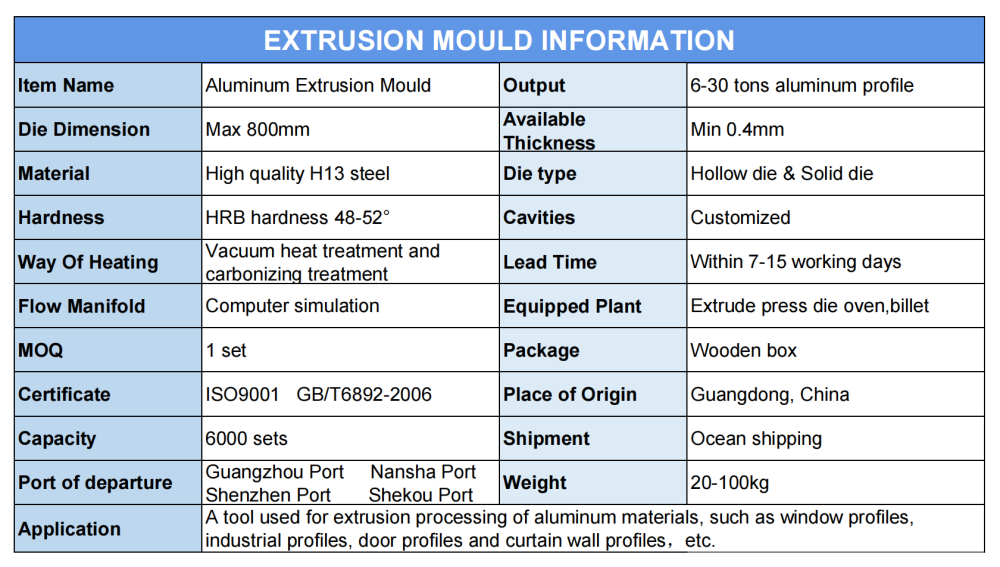

Working Principle of Aluminum Extrusion Die

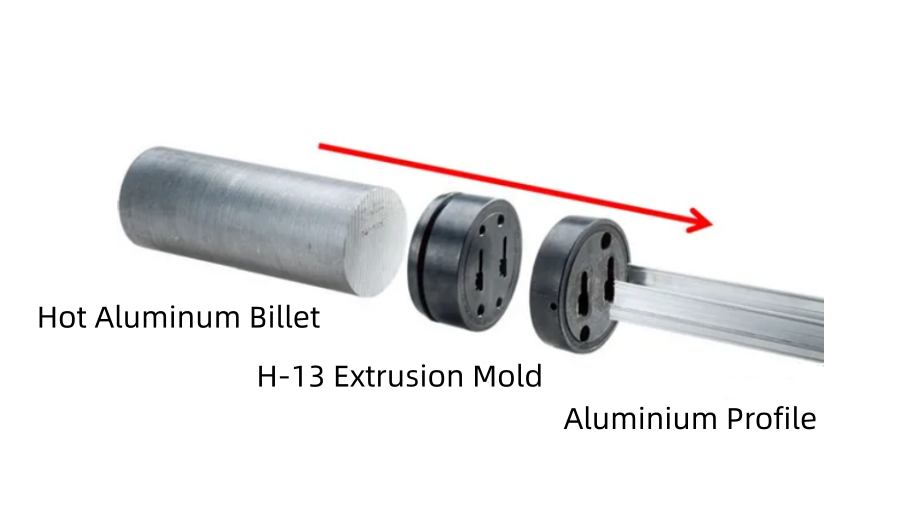

Let's first understand the forming steps of aluminum profiles. The aluminum profile processing process includes batching, rolling, extrusion, stretching, forging and other steps. Generally, factories will directly heat aluminum rods, and then extrude them through dies to obtain aluminum profiles of different cross-sections. , To put it simply, it is casting, extrusion and forming.

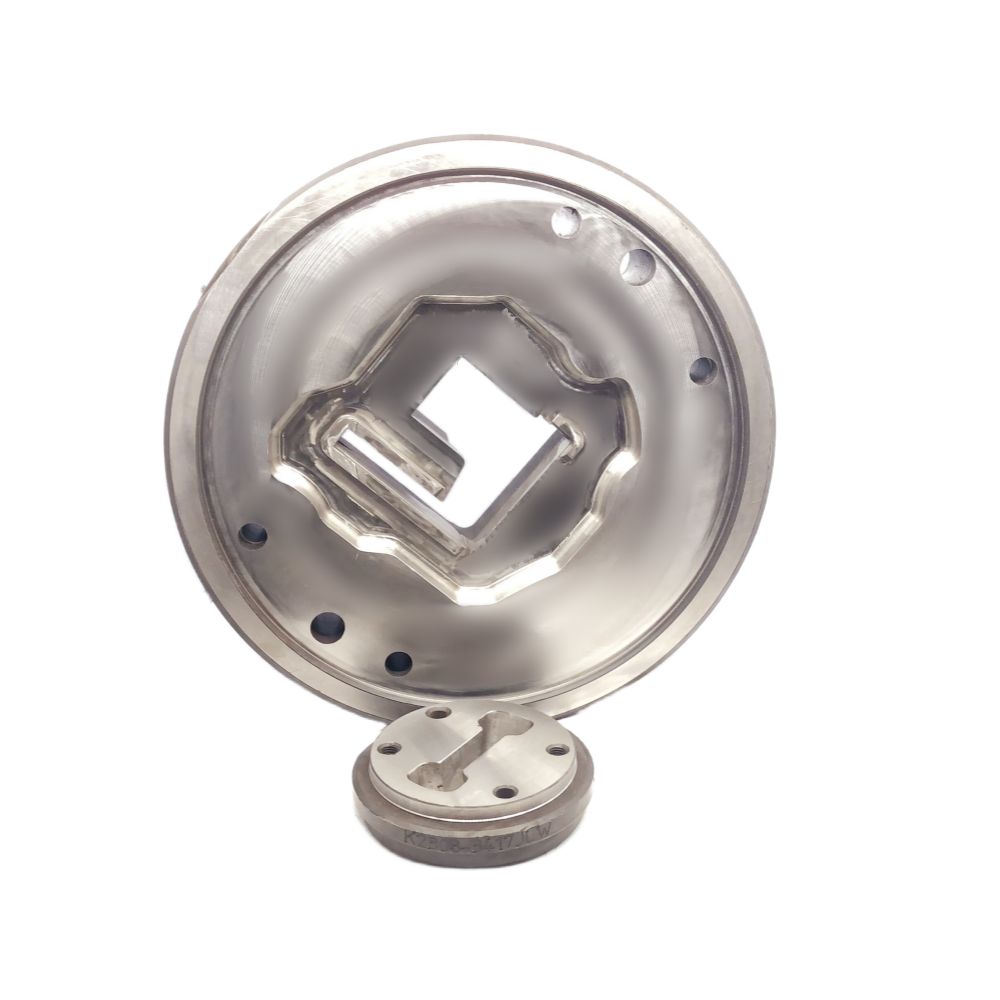

Extrusion requires an aluminum profile mold. The material of this industrial aluminum profile extrusion mold is H13 steel, and the mold needs to be nitrided before it can be used. Generally, a set of molds consists of three parts: the positive mold, the mold pad and the mold sleeve. The positive mold is composed of working belt, empty knife, deflector and other parts, and each component has its own function.

The formed gap flows out to form a hollow product of the required shape and size, and the number of welds of the product is the same as the number of strands of the metal flow.

Tempering Furnace

The tempering furnace is used for tempering general metal parts in air and quenching, annealing and aging heat treatment for aluminum alloy die-casting parts, pistons, aluminum plates and other light alloy parts.

The shell is welded by steel plate and section steel, and the trolley is welded by section steel and steel plate.

The trolley can reduce heat radiation and convection loss through soft contact with the furnace lining and sand sealing mechanism, and effectively ensure the sealing of the furnace body.

(Our tempering standard: 2 times*10 hours)

Applications of aluminum alloys in the automotive industry

Aluminum alloys are widely used in the automobile industry and are mainly used in the manufacture of various parts of automobiles, including body, engine, suspension system, rims, etc. Here are some specific applications:

1. Body and frame: The lightweight properties of aluminum alloy make it widely used in the manufacture of body and frame. Using aluminum alloys can significantly reduce the overall weight of a car, thereby improving fuel efficiency and reducing emissions.

2. Engine parts: The high thermal conductivity and excellent corrosion resistance of aluminum alloys make it very popular in the manufacture of engine parts. For example, aluminum alloys can be used to make engine cylinder heads, pistons, and radiators.

3. Suspension system: The strength and stiffness of aluminum alloy make it widely used in the manufacture of suspension systems. Using aluminum alloys can improve the performance and durability of your suspension system.

4. Rim: The lightweight and beautiful appearance of aluminum alloy make it very popular in the manufacture of rims.

5. Other components: In addition to the above components, aluminum alloys are also used to manufacture other components of automobiles, such as fuel systems, braking systems, electrical systems, etc.

In general, the application of aluminum alloys in the automotive industry can improve the fuel efficiency, performance and durability of the vehicle, while also improving the aesthetics of the vehicle.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold made of good industrial aluminum materials, we are the perfect partner for you.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like