car base extrusion mold 1

2 year ago

Precautions when using extruded aluminum molds:

1.Mold installation: When installing the mold, it is necessary to ensure that the mold is installed in the correct position and fixed stably to avoid the mold from shifting or falling off during the production process.

2. Temperature control: The mold will generate a lot of heat during use, and the temperature of the mold needs to be effectively controlled to prevent the mold from overheating and causing deformation or damage.

3. Cleaning and maintenance: During the use of the mold, regular cleaning and maintenance are required to ensure the service life of the mold. When cleaning, avoid scratching with hard objects to prevent damage to the mold surface.

4. Avoid overuse: During the use of the mold, excessive use should be avoided to prevent premature wear of the mold. Generally speaking, molds need to be replaced after being used for a period of time to ensure product quality.

5. Use appropriate lubricants: During the use of the mold, appropriate lubricants should be used to reduce mold wear and improve production efficiency.

6. Regular inspection: During the use of the mold, the mold needs to be inspected regularly to find out whether there are cracks, deformations and other problems in the mold so that they can be dealt with in a timely manner.

7. Use special tools: When disassembling and installing the mold, special tools should be used to avoid mold damage caused by using inappropriate tools.

8. Train operators: Operators need to receive professional training to understand the usage and precautions of the mold to avoid mold damage due to improper operation.

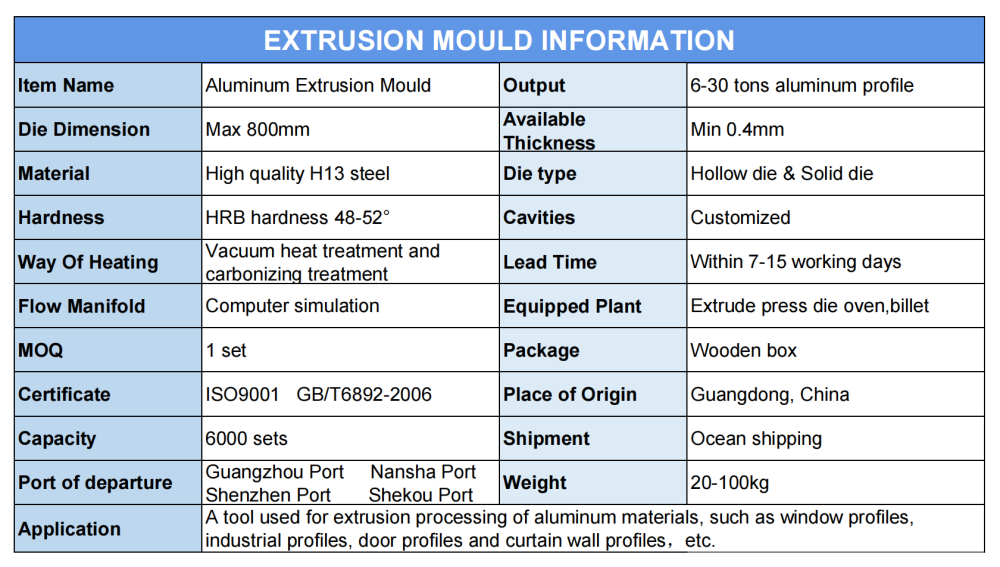

Introduction to aluminum extrusion mold

Aluminum extrusion die is a tool used for extrusion processing of aluminum materials. It is made of high-strength alloy steel and has the characteristics of wear resistance, corrosion resistance and high temperature deformation resistance. Aluminum extrusion molds are mainly used to produce aluminum profiles of various shapes and sizes, such as aluminum alloy door and window frames, aluminum alloy pipes, aluminum alloy elevator guide rails, etc.

The manufacturing process of aluminum extrusion molds is very precise. First, the molds need to be designed and manufactured according to the design requirements of the product. Then, it is processed by CNC machine tools to ensure the accuracy and quality of the mold. During the extrusion process, the aluminum material is heated to a certain temperature and then pressed into the mold through an extruder to form the required shape and size. Finally, after cooling and trimming processes, the final aluminum profile product is obtained.

Aluminum extrusion molds have high production efficiency and precision and can meet various complex product requirements. At the same time, because aluminum materials are lightweight, corrosion-resistant and have good thermal conductivity, aluminum profiles are widely used in construction, transportation, electronic appliances and other fields. Therefore, aluminum extrusion molds play an important role in modern industrial production.

In summary, the aluminum extrusion die is a critical tool used to produce aluminum profiles of various shapes and sizes. It has the characteristics of high strength, wear resistance, corrosion resistance and high temperature deformation resistance, and can meet various complex product requirements. Aluminum extrusion dies play an important role in modern industrial production and promote the widespread application of aluminum profiles.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

Aluminum resource distribution

The world's bauxite resources are relatively abundant. According to 2015 data from the United States Geological Survey, the world's bauxite resources are 55-75 billion tons. The world's proven reserves of bauxite are approximately 28 billion, mainly distributed in Africa (32%), Oceania (23%), South America and the Caribbean (21%), Asia (18%) and other regions (6%) .

From the perspective of country distribution, bauxite is mainly distributed in Guinea, Australia, Brazil, China, Greece, Guyana, India, Indonesia, Jamaica, Kazakhstan, Russia, Suriname, Venezuela, Vietnam and other countries.

Among them, Guinea (proven bauxite reserves of 7.4 billion tons), Australia (proven bauxite reserves of 6.5 billion tons) and Brazil (proven bauxite reserves of 2.6 billion tons) account for approximately 60% of the world's total proven bauxite reserves.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like