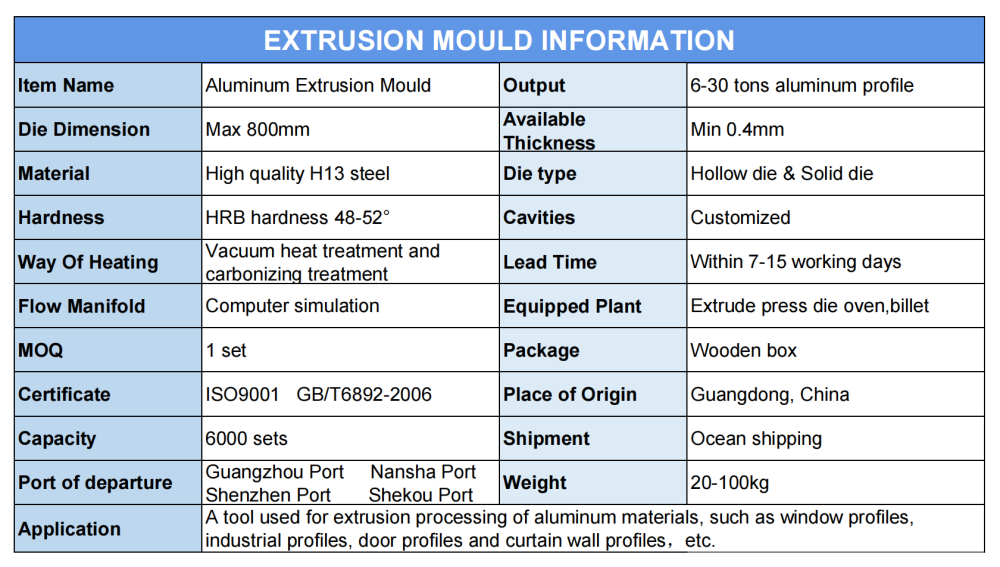

decorative profile mold 4

2 year ago

Advantages of Aluminum Extrusion Dies

1. The extrusion method can not only produce rods, pipes and other products with simple cross-sectional shapes, but also hollow and solid products with complex cross-sectional shapes.

2. The production flexibility of the extrusion method is very large. Products with different shapes and sizes can be produced only by changing the mold. The mold replacement time is short and the production efficiency is high, which is of great significance for the production scale of small batches.

3. The dimensional accuracy of extruded products is far better than that of rolling and die forging, and the surface roughness is better, so it can be processed without processing and become a finished product.

4. The mechanical properties of extrusion products are good, especially for aluminum and aluminum alloy products, the extrusion effect is that after quenching or aging, the longitudinal properties of the products are higher than those of rolling and die forging.

5. Compared with rolling, extrusion equipment has compact structure, less land occupation, less infrastructure cost, simple operation and easy maintenance.

6. It is easy to realize semi-automation or automation.

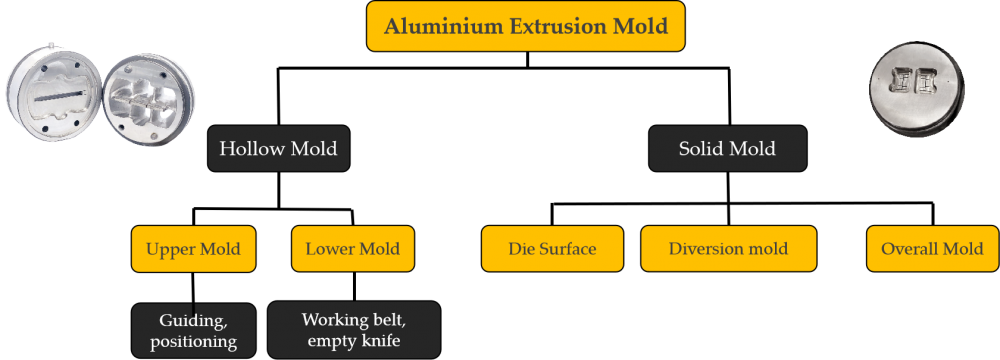

Structure of Aluminium Extrusion -Hollow Mold and Solid Mold

Aluminum profile extrusion dies can be divided into solid dies and hollow dies according to the shape of the extrusion section, and hollow dies can be divided into single-hole dies and multi-hole dies.

Hollow mold: It consists of two parts, the upper mold and the lower mold.

The general function of the upper mold is to guide the flow and position the hollow part of the hollow profile.

The lower mold is the outer surface working belt and empty knife.

Solid mold: Only one piece of mold including flow guide and working belt.

Aluminum alloys are widely used in lighting, mainly in the following aspects:

1. Lamp body material: Aluminum alloy has good thermal conductivity and corrosion resistance, so it is often used as the main body material of lamps, which can effectively dissipate heat and extend the service life of lamps.

2. Reflector: Aluminum alloy has excellent reflective properties and is often used as a reflector for lamps, which can improve the efficiency of light and reduce energy consumption.

3. Radiator: Some high-power lamps, such as LED lamps, will generate a lot of heat. Aluminum alloy has good heat dissipation performance and can be used as a radiator for lamps to prevent the lamps from overheating and ensure their stable operation.

4. Lamp stand: Aluminum alloy has high strength and light weight. It can be used as a light stand for lamps to support the weight of the lamp. It can also reduce the weight of the lamp and facilitate installation and movement.

5. Decoration: The surface of aluminum alloy can be processed in a variety of ways, such as anodizing, electrophoretic coating, spraying, etc., which can change its color and gloss and improve the decorativeness of the lamp.

Therefore, aluminum alloys are widely used in lighting, which can not only improve the performance of lamps, but also improve their aesthetics.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Foshan Jieliwei Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile

You May Also Like