3. When machining finished, the professional testing personnel will do 100% retesting again..

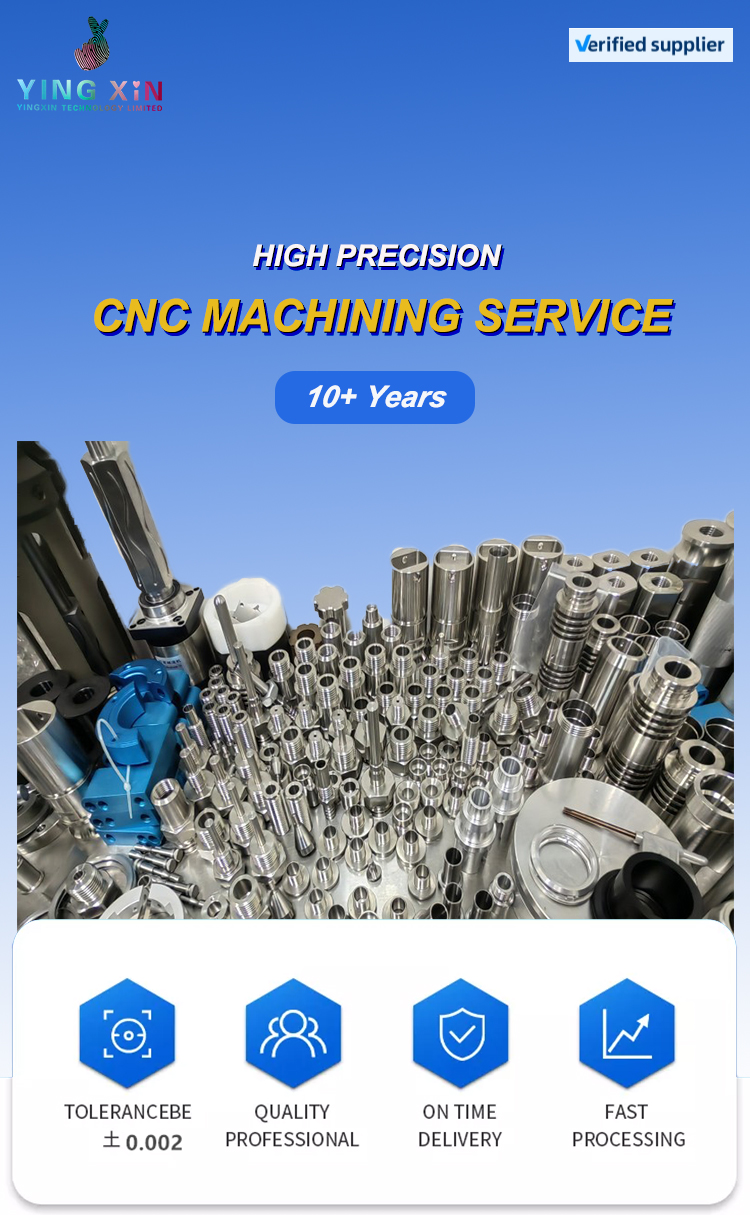

Precision Custom Cnc Machining Parts Stainless Steel Copper Brass Aluminum components Lathe Milling Titanium Cnc Parts1

2 year ago

Precision Custom Cnc Machining Parts Stainless Steel Copper Brass Aluminum Spare Cnc Lathe Milling Titanium cnc Parts

We Support Custom CNC Machining Parts of Most Materials (Non-Standard Parts) | ||

Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) | |

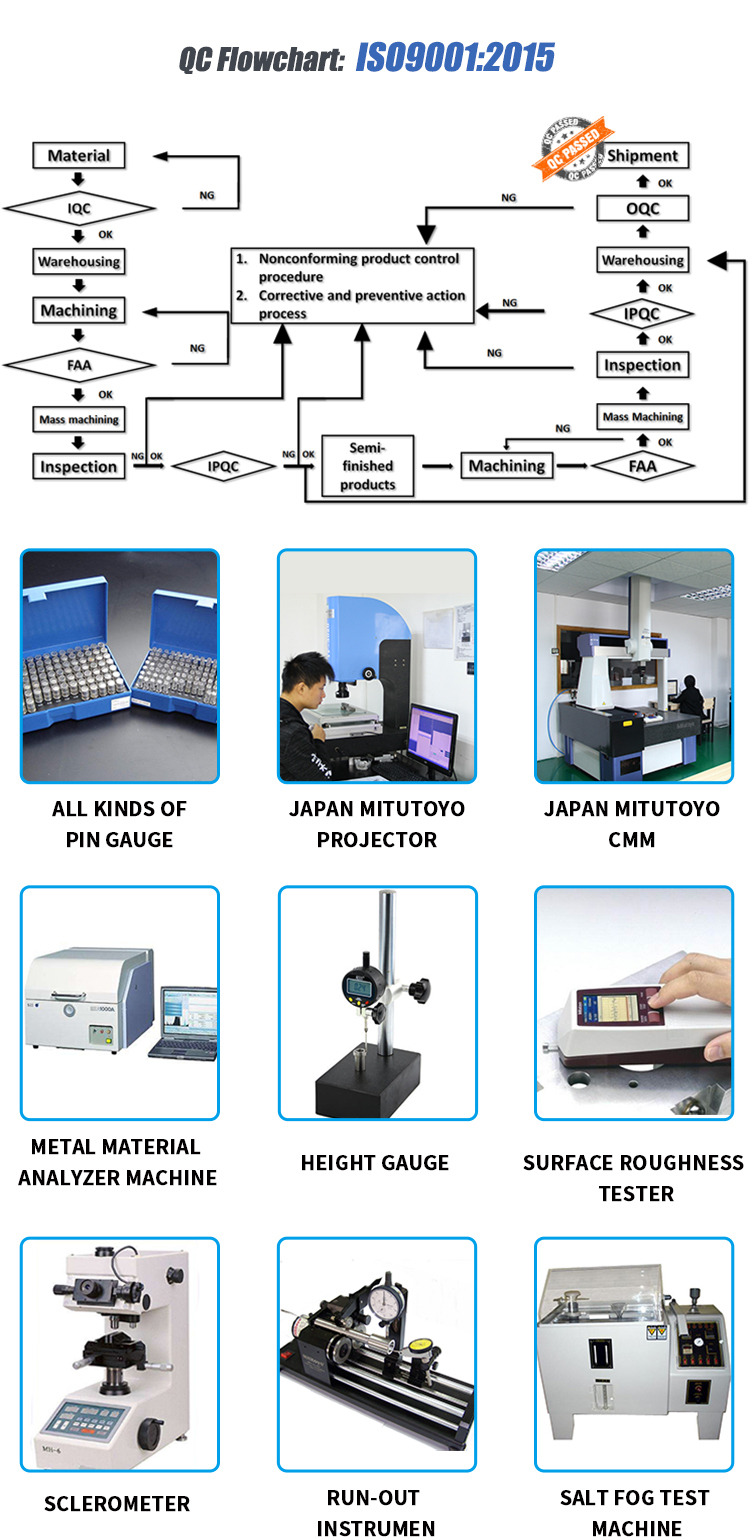

Quality Assurance | ISO9001:2015/SGS/TUV/RoHS | |

Process | CNC Turning, anodized Milling, turning-milling compound, drilling, auto lathe, tapping, brushing, surface treatment, etc. | |

Tolerance | ±0.01-0.05mm, 100% QC quality inspection before delivery, can provide quality inspection form. | |

Roughness | Ra0.2 - Ra3.2(Custonize avaiable) | |

Materials Avaiable | Such as aluminum, copper, stainless steel, iron, PE, PVC, ABS, etc. | |

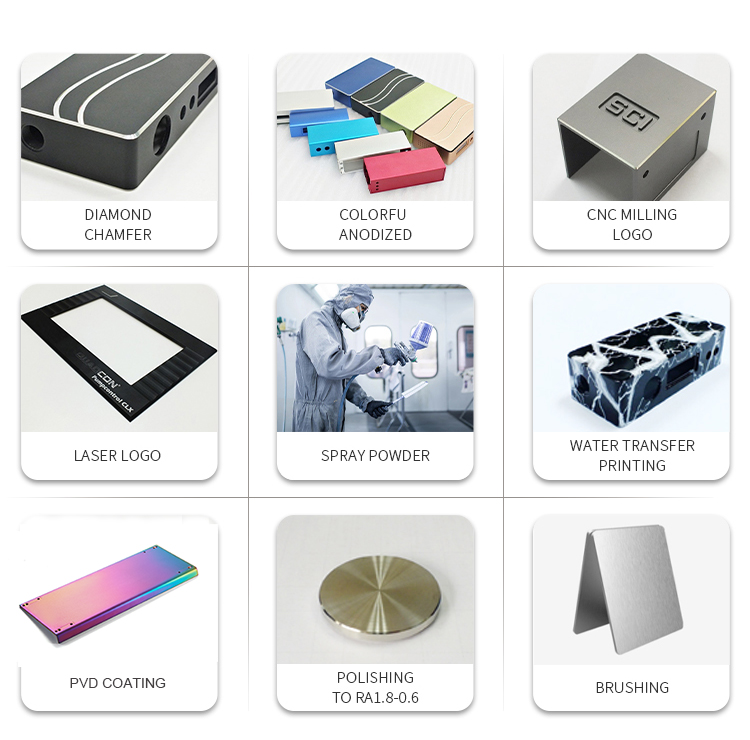

Surface Treatment | Blacking, polishing, anodize, PVD, spraying, chrome plating, zinc plating, nickel plating, tinting, etc | |

Color | White, black,silver, red, grey, Pantone and RAL, etc. | |

Testing equipment | CMM; Tool microscope; Projecting apparatus; Automatic height gauge; Manual height gauge; Dial gauge; Marble platform; Roughness measurement, Salt spray tester, RCA paper tape abrasion tester, Coating thickness tester, etc. | |

Applications | Industrial Equipment, electronic product, smart home, jewelry, watch case,artware etc. | |

Service | OEM/ODM/One-stop customized CNC machining service, provide design drawing analysis service, production and technical service, assembly service, etc | |

File Formats | JPG, PDF, CAD, DWG, STP, STEP | |

Drawing | Please provide design drawings and contact our sales manager, if there are no drawings can send samples/sample photos to get a free quotation. To help us offer the best service for you. Please be sure your drawings are clear and accurate(including processing,quantity,materials, precision tolerances, surface treatment, and special requirements) | |

Packing | 1. Regular: Paper, Foam, PE bag, Carton | |

2. According to customers' requirements | ||

3. When machining finished, the professional testing personnel will do 100% retesting again..

deformation

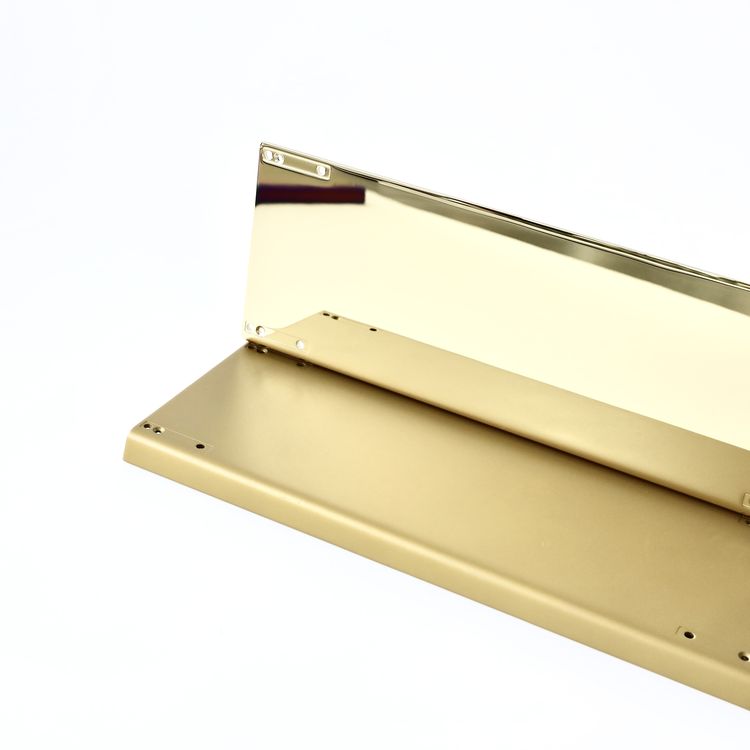

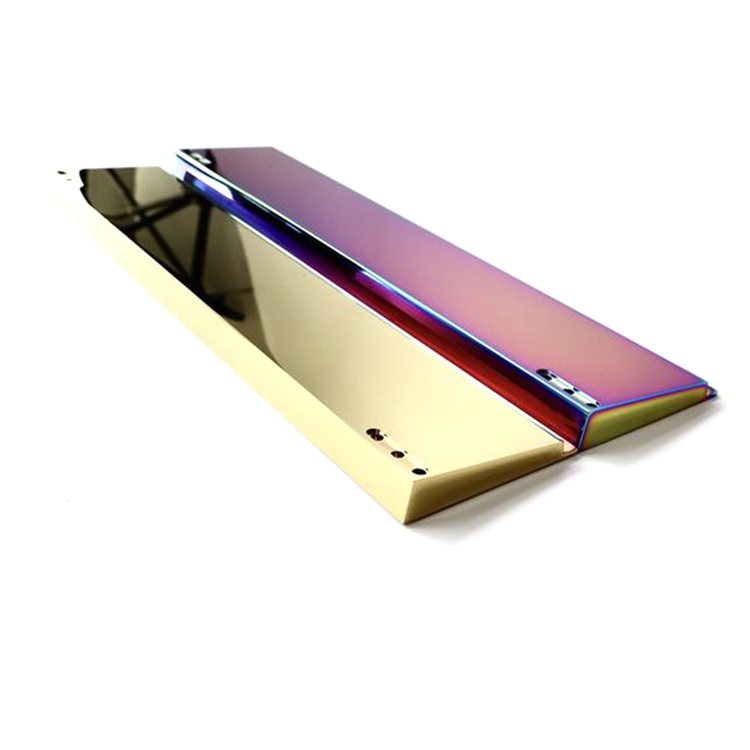

glossy,strong stereoscopic feeling

precision, stable quality, fastening and durable

Product Name | Precision Custom Aluminum Stainless Steel Cnc Turning Parts Small Metal Parts CNC Turning Service | ||||

Material | aluminum, stainless steel, brass | Size(mm) | according to customer's needs | ||

Color | gold, black, silver,rose gold.... | Features | precision,stable,durable,personality... | ||

Processing | CNC machining, Polishing, PVD | Packing | opp bag, export carton | ||

Application | Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment,etc | ||||

Yingxin's Workshop

It has 35 CNC machines, 8 complete polishing lines (128 stations), 30 flat grinders, 4 electric polishing machines, bending machines, 6 PVD machines, dust-free workshops, automatic control systems, and supporting processes such as brushing sandblasting, anodizing, electro plating, PVD coating, exposure development, etching, and oil filling.

Surface Treatment Available___________________________________________________________________________

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Yingxin Technology Co., Ltd.

- *Message:

-

Submit

Main Product:

Mechanical Keyboard,

Mechanical Watch,

Phone Case,

Quartz Watch,

Watch Accessories,

Keyboard Accessories

You May Also Like