Industrial Tungsten Carbide Blades For Different Blades and Size1

2 year ago

Tungsten Carbide Blades For Different Blades and Size

Ceramics, printing machinery, paper industry, carton, forestry, rubber, plastics, food machinery, textile, electrical appliances, light industrial machinery, metallized film, tobacco, cigarette machinery, packaging materials, electronic appliances, wire, cable, shipbuilding, chemical fiber, glass fiber, textile, feed paper tube, forestry, woodworking machinery, plastic crushing, edge sealing, middle sealing machinery, bottom sealing bag making machine, wood processing, food Product packaging, metallurgical machinery, rubber, etc

The thin blade knife, with its razor-sharp edge, excels in precise cutting tasks, making it a popular choice in various industries. Industrial blades, on the other hand, are built to last, withstanding the rigors of continuous use in heavy-duty applications. Among these, the circular knife blade stands out for its ability to deliver smooth and even cuts, enhancing production efficiency. These Industrial Slitter Blades, each with its unique characteristics, contribute significantly to the success of various industrial cutting processes.

|

Product introduction

|

product introduction

|

|

|

Material

|

Raw material tungsten steel, hard alloy

|

|

|

Feature

|

1. Excellent quality, high production efficiency 2. Tungsten steel material, can work in high temperature environment

|

|

|

Use

|

Mainly used for Corrugated cardboard,paper, film, gold, silver foil, aluminum foil, copper foil, tape and other items cutting

|

|

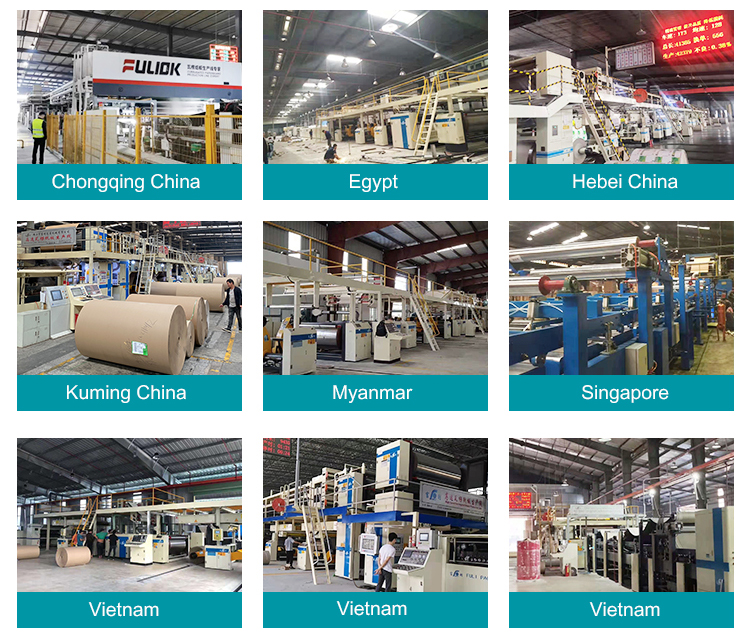

A: Our factory is located in Foshan City, Guangdong Province, China.

For most of machines, engineers team provides solutions in the field of Mechanic/ Electric/ Operation.

TM online for 24 hours.

One year warranty period under normal use for most of machines.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt ,

Printer Slotter Die Cutter

You May Also Like