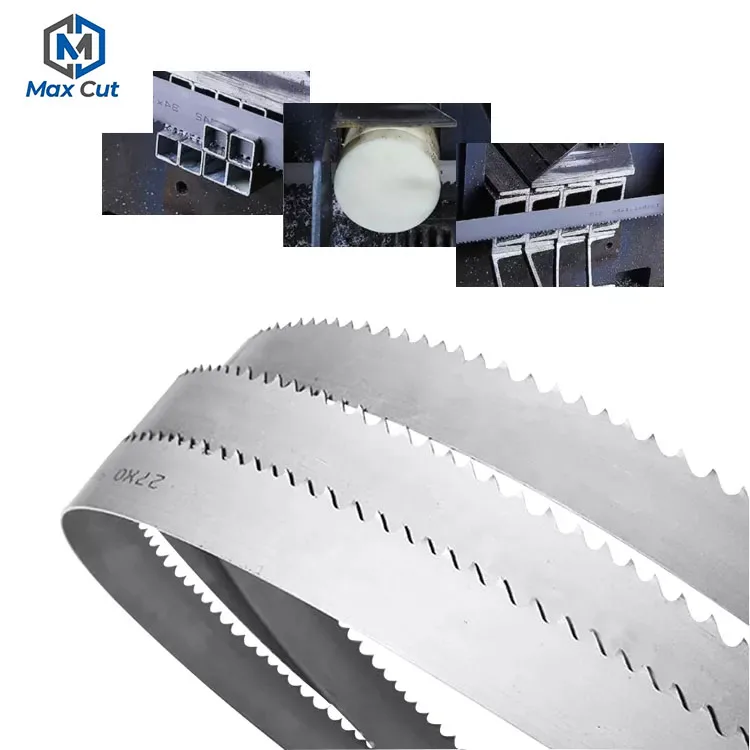

Grooved Great Wall Band Saw Blade For Graphite Jade Monocrystalline Silicon Cutting1

2 year ago

|

Product name

|

Bi-metal Band Saw Blade

|

|

|

||

|

Service

|

ODM&OEM

|

|

|

||

|

Material

|

HSS M35/M42/M51

|

|

|

||

|

Material Cutting

|

Alloy steel/carbon steel/

Stainless steel/mold steel

|

|

|

||

|

Details

|

Preferred material、Serrated sharp

|

|

|

||

Advanced Blade Technology: This M42 8% Cobalt Bi-Metal Band Saw Blade is engineered for longevity. The high-speed steel edge delivers formidable cutting power, while the tempered alloy backer provides the necessary fatigue resistance to extend the blade's life.

Distinct Advantages of Bi-Metal Band Saw Blades

Reduced Blade Replacement: These blades offer an extended lifespan, minimizing the need for frequent changes.

Quiet Operation: Our innovative processing reduces noise significantly during cutting.

High-Quality Cutting Results: The specialized teeth setting ensures excellent cutting quality and a smooth finish.

Strength and Resistance: The combination of a high-speed steel edge and a tempered alloy backer provides durability and fatigue resistance for a long-lasting blade life.

In the precision machinery manufacturing industry, slitting saw blades, slotting machine saw blades, and band saw blades each play an indispensable role. These efficient tools are widely used in the precise division of metal plates, the creation of complex slots and holes, and the continuous cutting of long materials. For instance, in the production line of automotive components, slitting saw blades are capable of accurately slicing thick steel plates to the desired widths, preparing them for subsequent stamping and forming. Meanwhile, slotting machine saw blades excel at rapidly cutting precise slots and holes into metal parts, meeting the stringent requirements of assembly. As for band saw blades, with their unique continuous cutting method, they demonstrate remarkable efficiency in the lengthwise cutting of materials such as wood, metal, and even some non-metallic materials, ensuring the smooth and efficient flow of the production process. Together, these three tools collaborate to drive the manufacturing industry towards greater refinement and efficiency.

|

Width

|

Thickness

|

Tooth Pitch

|

|

19mm

|

0.9mm

|

2/3TPI 3/4TPI 4/6TPI 5/8TPI

|

|

27mm

|

0.9mm

|

2/3TPI 3/4TPI 4/6TPI 5/8TPI

|

|

34mm

|

1.1mm

|

2/3TPI 3/4TPI 4/6TPI

|

|

41mm

|

1.3mm

|

2/3TPI 3/4TPI 4/6TPI

|

|

54mm

|

1.6mm

|

2/3TPI 3/4TPI 4/6TPI

|

|

67mm

|

1.6mm

|

2/3TPI 3/4TPI 4/6TPI

|

|

80mm

|

1.6mm

|

0.75/1.25 1.4/2 1/1.5 2/3

|

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like