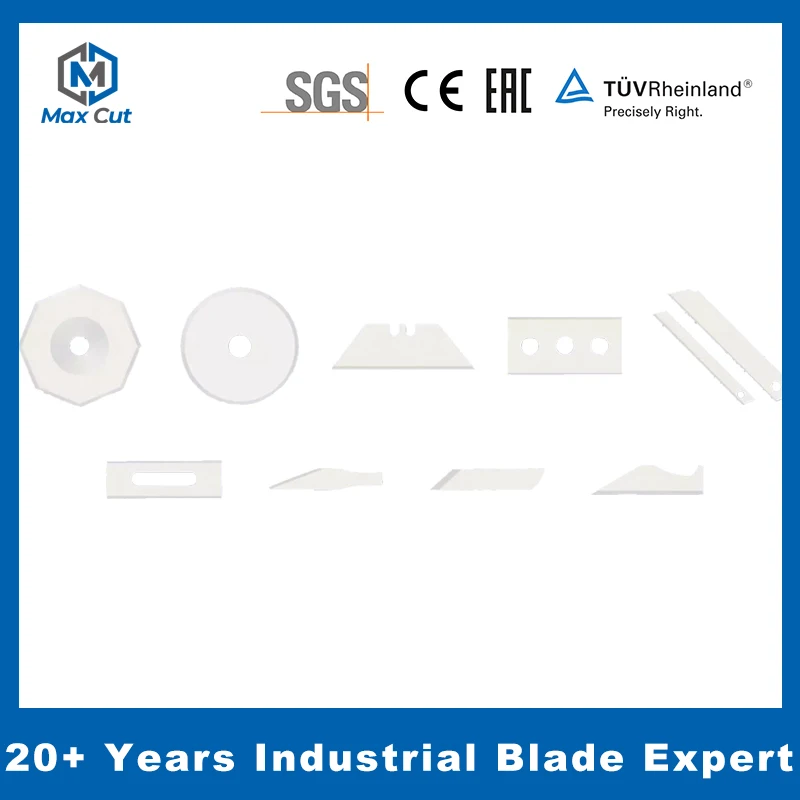

Anti-Static 45*8*0.4mm Non woven Fabric Slitting Knife Zirconia Ceramic Round Blade1

2 year ago

fabrics, synthetic fabrics, natural cotton fabrics, etc.

Ceramic blade features: high hardness, high density, high temperature resistance, high toughness, clean cutting surface, good wear

resistance, good corrosion resistance, low friction coefficient, insulation, no static electricity, etc.

|

Product Name

|

ceramic round blade, suitable for handhold fabric cutting machine, automatic cutting machine

|

|

General Specifications

|

Round blade Φ45*8*0.4mm

|

|

Delivery Time

|

2-7 workdays

|

|

OEM

|

can be customized according to requirement LLY PACK (Foshan) Co., Ltd is one of the leading manufacturers for corrugating roller and all types of industrial knives and cutting blades. Our brand"Max Cut" is committed to supply the durable and accurate cutting products to our customer without the troubles.

Our factory is located in Foshan City, Guangdong Province, South China.

A state-of-the art factory with over 30 sets of high precision CNC machine and the most advanced heat-treatment equipment.

Over 20 years of technical experience, we have been continuously striving for top quality cutting knives. We strictly following our standard quality control.

Max Cut products are widely applied in various industries, such as: Corrugated Cardboard & Carton Packaging Industry, Paper Mill, Tissue& Towel converting, Plastic& Flexible Packaging Industry, Food Packaging, Tobacco Cutting, Fabric& Textile & Leather Cutting, Film& Foil Cutting, Tube Cutting, Metalworking, Wood processing, Shredder/Crusher Blade and more.

Max Cut is always ready to support you the industrial cutting knives with expected quality at the best price and reliable turnaround time.

Please join us for"Win-win cooperation"

|

medicinal materials industry, sheet metal industry, rubber industry, food industry, leather industry, packaging industry, printing

industry, woodworking industry, textile industry, etc

a mold under a heavy pressure of 300 tons at a high temperature of 1750 degrees, and then grinded and cut into a finished ceramic

blade with a diamond grinding wheel. Ceramic blades are new types of blades with sharpness in industrial applications. The service

life of ceramic knives is 100 times longer than that of high-speed steel blades and more than 3-13 times longer than that of

tungsten carbide blades.The ceramic blade has the characteristics of high hardness, high density, high temperature resistance,

anti-magnetization, oxidation resistance, and no static static loading.

A1: Our factory is a professional manufacturer of industrial blades for more than 20years.Our blades are mainly used in:

packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.

Q2: What is your blade hardness?

A2: Different material has different hardness, from 48HRC to 68HRC, we can supply all of these. You can describe the use, we'll

provide suitable suggestion for you.

Q3. Where were cutting blades exported before?

A3: Our industrial blade have been exporting to over 40 countries, including: Vietnam, Thailand, Myanmar, Philippine, Malaysia,

Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia, Lithuania, Mexico, Brazil, Argentina, Venezuela,

Honduras, Korea and etc.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers ,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like