Computer Cutting Tungsten Steel Decagonal Round Ten-sided Slitting Blade1

2 year ago

Tungsten Steel Decagonal Round Ten-sided Slitting Blade

Tungsten Carbide Steel Blade Details

Material Composition: Predominantly made of tungsten carbide steel. Hardness Level: Falls within HRC90° to 93°. Material Density: Measured at 15.5KG/DM3. Distinctive Features: 1. Exceptional quality for increased production efficiency. 2. Constructed using tungsten steel, suitable for high-temperature environments. Applications: Ideal for cutting a variety of materials such as paper, different types of film, and a range of foils (gold, silver, aluminum, and copper), including magnetic tapes. Industry Use: Extensively applied in numerous fields, including ceramics, printing equipment, paper production, box manufacturing, the forestry sector, the rubber and plastics industry, machinery for food processing, lightweight textiles and industrial equipment, films with metallic coatings, tobacco and cigarette machine manufacturing, packing materials, electronics, wire and cable fabrication, shipbuilding, chemical and glass fiber production, textiles, animal feed processing, paper tube manufacturing, woodworking, plastic grinding, various machinery for sealing, wood processing, food packaging, metallurgy, and rubber manufacturing, among others.

The Tungsten Steel Blades are renowned for their exceptional durability and precision, making them a preferred choice for various industrial applications. The Tungsten steel round Blade, with its circular design, offers smooth and efficient cutting, while the paper box slitting blades are specifically tailored for precise slicing of paper materials. These blades, together, demonstrate the versatility and reliability of Tungsten steel in blade manufacturing.

|

Material

|

Tungsten Steel Carbide

|

|

Shape

|

Round /Ten-sided

|

|

Delivery Time

|

7-15 workdays

|

|

Application Industry

|

Textile,Paper,Fabric Plastic

|

1. Prolonged service life, minimizing the need for regular blade replacement, thus boosting productivity.

2. Made of materials that are both wear and high-temperature resistant, suitable for use in heated environments.

3. Ultra-sharp blade design ensures smooth, accurate cuts without any burrs.

|

Common Size (OEM/ODM Available)

|

|

|

|

|

|

||||

|

Outer diameter(MM)

|

Outer Diameter

|

Inner diameter(MM)

|

Thickness

|

Thickness(MM)

|

|

||||

|

25

|

108

|

8

|

7

|

0.63

|

|

||||

|

28

|

108

|

8

|

20

|

0.63

|

|

||||

|

32

|

118

|

8

|

8

|

0.63

|

|

||||

|

36

|

88

|

8

|

7

|

0.63

|

|

||||

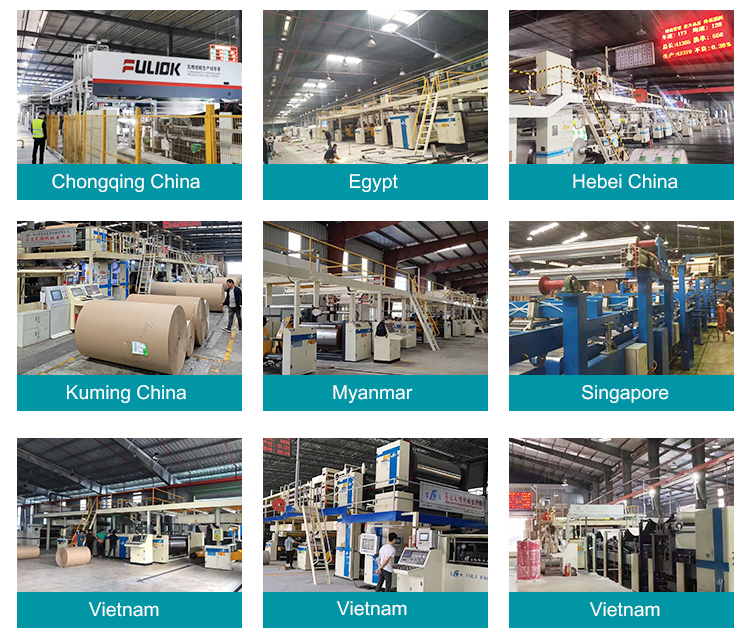

A: Our factory is located in Foshan City, Guangdong Province, China.

For most of machines, engineers team provides solutions in the field of Mechanic/ Electric/ Operation.

TM online for 24 hours.

One year warranty period under normal use for most of machines.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line ,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like