stamping parts

2 year ago

The produced parts are including Auto parts,Agricultural machinery parts, construction scaffolding parts Marine valve and pump components and hydraulic parts etc. Architectural,Machinery,Medical; Food Machinery, Valves and so on. The material which we used Aluminium; Bronze; Brass; Copper; carbon steel; stainless steel and so on.At the same time, we can offer the CNC machining; Phosphating; Blackening Processing;Hot Dip Galvanizing: Powder Coating: Painting: Plating, Assembly for customers.

85% products are sold to overseas, the customers are from America, Canada, Europe Union, etc.

We are specializing in:

1. Sand casting (Grey iron, ductile iron, aluminum,etc.)

2. Investment casting (carbon steel, stainless steel, alloy steel,etc.)

3 . Die casting(aluminum, zinc, etc.)

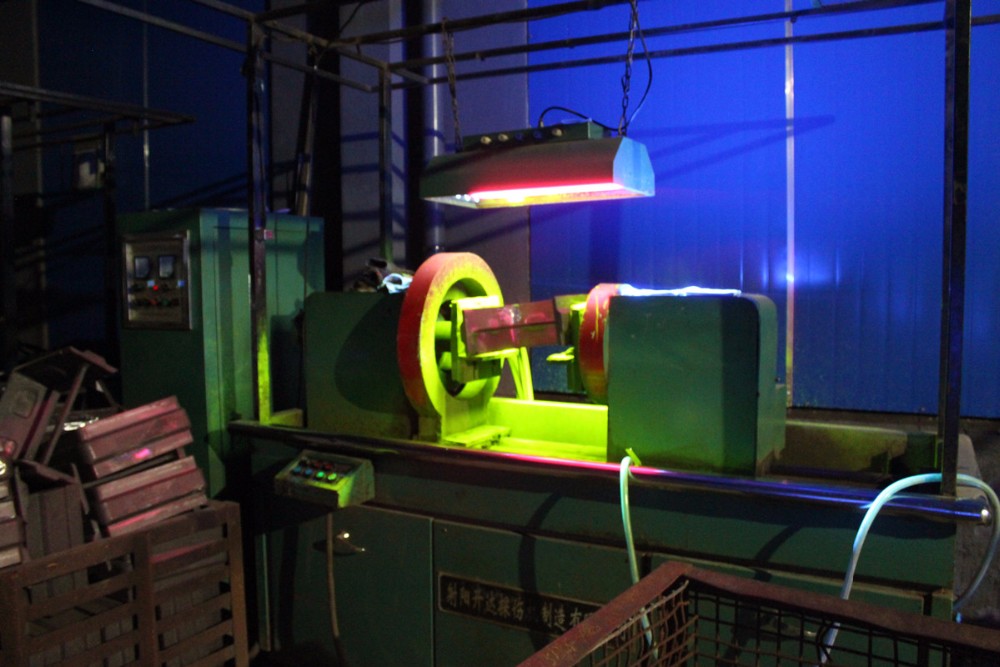

3. CNC Machining(CNC Center, CNC lathe, lathe, drilling machine, milling machine, pressing machine, etc.)

Certificate: ISO9001:2015, TS16949

Our Service

|

Products

|

According to the customers' technical drawings or samples

|

||

|

Casting Material

|

Cast Iron,ductile iron,Grey iron,aluminium,aluminium alloy,copper,bronze,GG25,GG20,GGG40,GGG50,GGG60,GGG70;QT400-18;QT450-10,QT600-3;QT700-2;FCD400;FCD450;60-40-18,65-45-12,ect.

|

||

|

Casting Product Weight

|

available from 0.02kg to 3000kg

|

||

|

Surface Treatment

|

*Oxidation

|

*Painting

|

*Plating Zinc

|

|

*Hot galvanized

|

*Electroplating

|

*Powder coating

|

|

|

*Sand blasting

|

*Vibration Grinding

|

*Electrophoresis

|

|

|

Inspection

|

*100% inspection before shipping,offer the material reports and mechanical property reports

|

||

|

*Control Plan and PPAP documents according to the clients' requirements

|

|||

|

*ISO9001:2015 quality control system

|

|||

|

Extra Service

|

*CNC machining service in our machining workshop

|

||

|

|

*The dimensions and outside shape are similar with investment casting

|

||

|

*The surface roughness is good from 2.5 to 25µm(100 to 1000µm)

|

|||

|

*The min. thickness can meet 3mm(0.120inch)

|

|||

|

*decrease the internal crack and keep close structure

|

|||

|

*As no joint and defect,the cleaning and machining work can be less

|

|||

|

*It's cheaper because it's a simpler process and the foam is cheaper than the wax

|

|||

Packing Details : sea Packing,air package; bubble bags;paper cartons, less than 1000kgs per pallet

Delivery Details : according to the customer required delivery time

Inspect the inner defects of the products,such as the cracks or air holes which can't be found by eyes.

Spectrum Analysis Tester

Inspect the chemical compostion of each furnace before casting,gaurantee that all produced parts will be according to the customers' requirements

Tensile Strength tester

Inspect the mechanical property for the different material parts

CMM is Coordinate Measuring Machine can inspect the space dimensions(X;Y;Z axis); widely used for Auto. parts

Ultrasonic tester inspects the inner defects of the casting parts.

Q: Are you trading company or manufacturer ?

A: We are OEM,owns the casting foundry and CNC machining workshop

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

we can discuss with my customers by email or face to face.

If you have another question, pls feel free to contact us as below:

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Ningbo City Yinzhou Ruican Machinery Co.,Ltd

- *Message:

-

Submit

Main Product:

Steel Castings and Iron Casting Parts,

Cnc Machining Parts,

Food Machinery Parts,

Agricultural Machinery Parts,

Construction Machinery Parts,

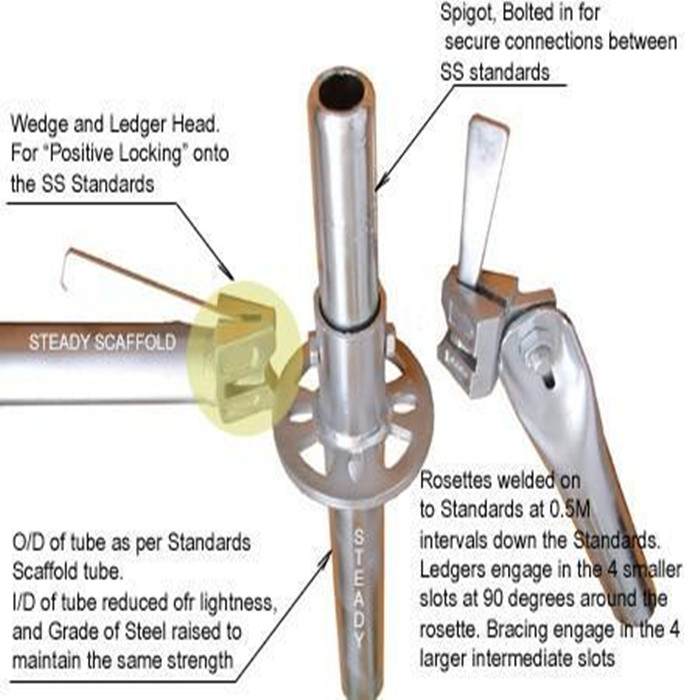

Scafflolding Parts

You May Also Like