OEM Engine hood cover Hood Engine accessories for NO. YD-215RD0731

2 year ago

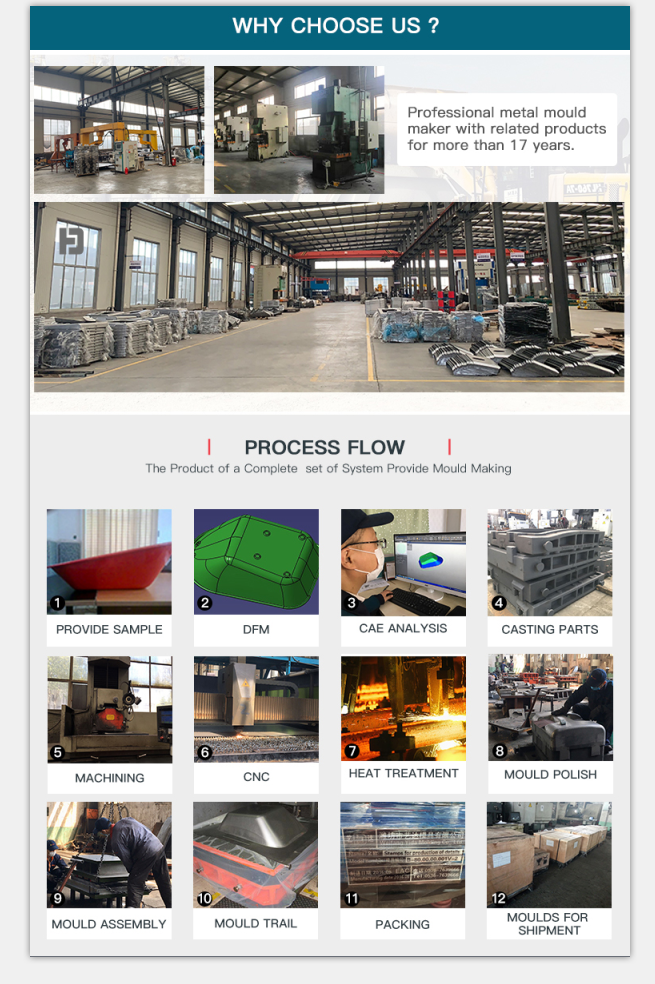

An automotive frame car door stamping die punching mold is a specialized tool used in the manufacturing process of car doors. It is designed to shape and cut the metal sheets used to create the car door frame. The mold consists of multiple components, including punches and dies, which are used to create the desired shape and cutouts in the metal.

The die punching mold is typically made from high-strength steel to withstand the high pressures and forces involved in the stamping process. It is precision-engineered to ensure accurate and consistent results in each production cycle.

The process begins with a flat metal sheet being fed into the stamping machine. The die punching mold then comes into action, as the metal sheet is pressed between the punches and dies. The punches apply pressure to deform the metal sheet, while the dies provide support and shape the metal into the desired form.

The mold can include various features, such as embossing, flanging, or perforations, depending on the specific design requirements of the car door frame. These features are created by the punches and dies in the mold, which are carefully positioned and aligned to achieve the desired outcome.

Once the stamping process is complete, the car door frame is removed from the mold and undergoes further manufacturing steps, such as welding, painting, and assembly, to complete the car door assembly.

Meet your various needs and provide customized molds, such as Diesel Engine Parts, Portable Concrete Mixer,Bucket Mould, Please contact us

Similar Video Recommendation

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Weifang Yida Mould Co.,Ltd

- *Message:

-

Submit

Main Product:

Punching mould,

Wheelbarrow mould,

Auto panel mold,

Deep drawn mold,

Sheet metal fabrication ,

Metal part