Custom sheet metal fabrication metal stamping deep drawing parts1

2 year ago

Sheet metal stamping and deep drawing parts can be customized in various ways to meet specific requirements. Some of the customization options include:

1. Material selection: The choice of material for the parts can be customized based on the specific application requirements. Different types of metals such as steel, aluminum, copper, and brass can be used, each offering unique properties such as strength, corrosion resistance, and conductivity Wheelbarrow Mould.

2. Dimensional customization: The dimensions of the parts can be customized to meet specific size and shape requirements. This can include varying thickness, length, width, and depth of the parts.

3. Surface finish: The surface finish of the parts can be customized to achieve the desired appearance and functionality. Options for surface finish customization include painting, powder coating, anodizing, plating, and polishing.

4. Tolerance and precision: The level of tolerance and precision of the parts can be customized to ensure that they meet the required specifications for fit and function.

5. Tooling and die design: Custom tooling and die designs can be developed to produce parts with complex shapes and features. This can include the design of punching moulds, wheelbarrow moulds, and other specialized tooling for specific applications Punching Mould .

6. Custom features: Additional custom features such as embossing, engraving, and perforation can be incorporated into the parts to meet specific design requirements.

7. Integration with other components: Parts can be customized to integrate with other components or assemblies, such as diesel engine parts, to ensure compatibility and seamless operation.

Overall, customization of sheet metal stamping and deep drawing parts allows for the production of components that are tailored to the unique requirements of a given application, resulting in improved performance, durability, and cost-effectiveness Diesel Engine Parts.

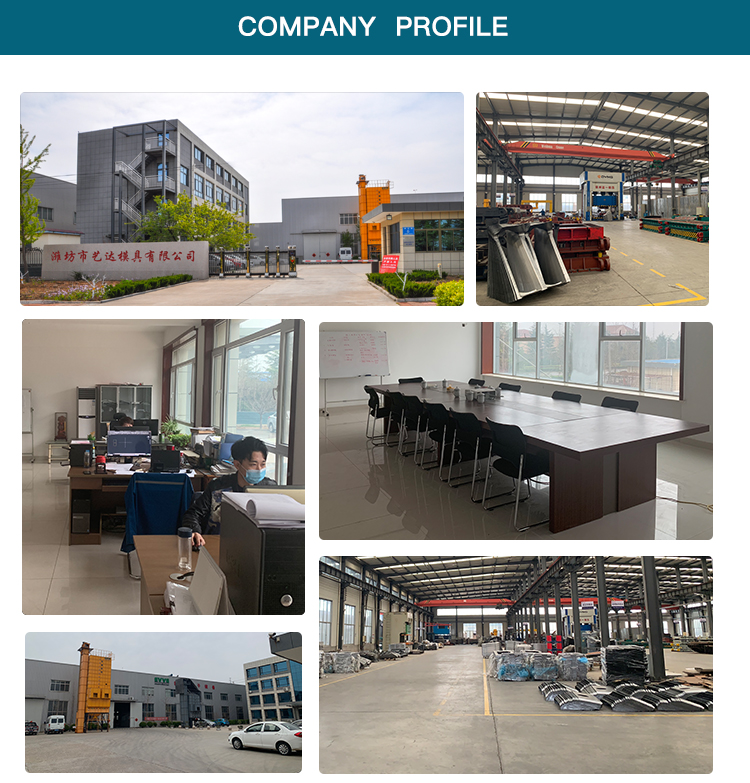

Weifang Yida mould Co., Ltd was established in 2003 which is a professional manufacturer in

designing and producing mould products for more than 19 years.

Factory covers 1 3,055 square meters with 108staff including 6 R&D.

Mould of wheelbarrow tray, automobile panel mould, fuel tank mould, vehicle transmission mould,

large with deep cavityspecial-shape stretching mould is our mainproducts.

To produce finished hardware products, in 2012,a branch factory was established, specializing in the production of fnished automobile panel covering, wheelbarrow tray, oil pans, vehicle

transmissions, 304 stainless of meat grinder barrel, mixer tray, portable concrete mixer and any

metal related punching parts.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Weifang Yida Mould Co.,Ltd

- *Message:

-

Submit

Main Product:

Punching mould,

Wheelbarrow mould,

Auto panel mold,

Deep drawn mold,

Sheet metal fabrication,

Metal part

You May Also Like