Photo_Video_010

11 month agoCentrifuge spray dryer of formaldehyde resin,formaldehyde amino resin ,formaldehyde epoxy resin.spray equipment for formaldehyde resin,formaldehyde amino resin,formaldehyde epoxy resin

Specifications

Work Principle Description

After filtering and heating, the air enters into the hot air distributor at the top of the centrifugal spray dryer, and the hot air will spirally and evenly goes into the drying chamber. The material liquid via high-speed centrifugal atomizer rotates into extremely thin vaporific liquid globule and parallelly flows with the hot air, and then the liquid will be dried into powdery products in a very short time (5-10 seconds). The waste gas after filtering will be expelled through the fan. For the wet organic solvent materials, the spray drying machine can be designed with closed cycle process. It can utilize cyclic nitrogen to dry the materials.

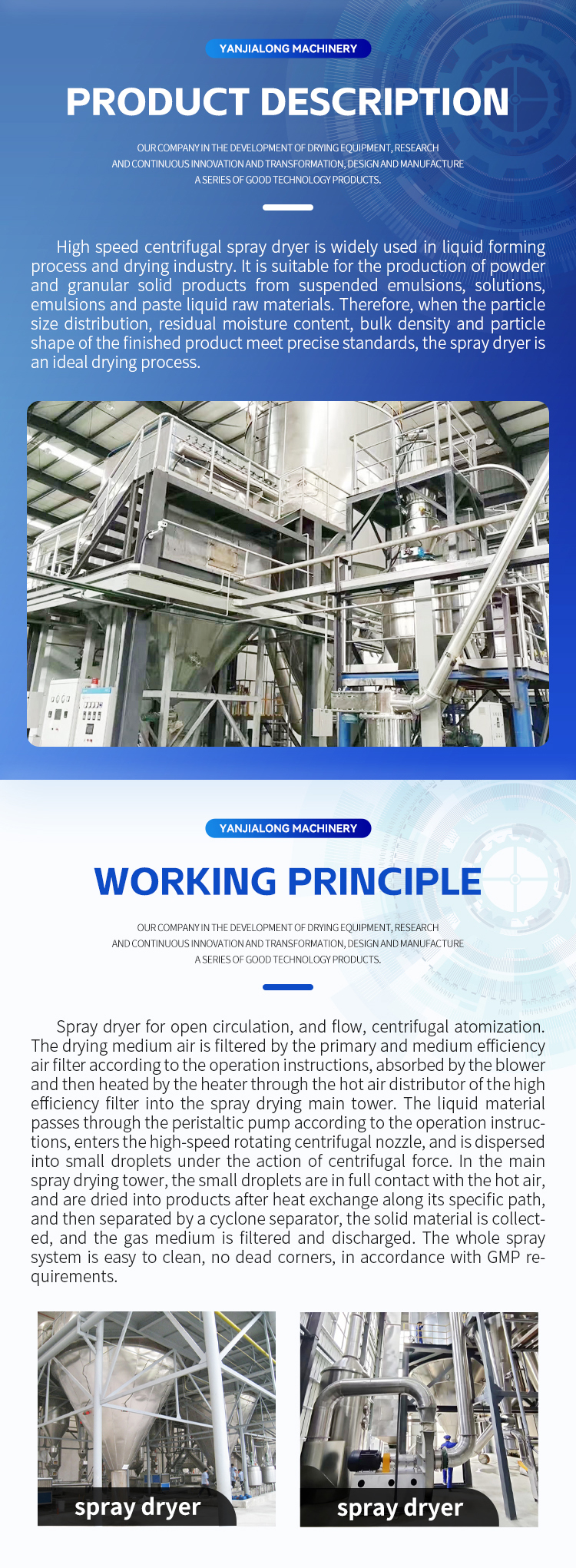

Machine Pictures

Application of Spray Dryer for PF resin

We are the spray dryer national stardard maker, our spray dryer is widely used for sheep blood, bovine(ox) blood, Pig blood etc.

With high drying efficiency, large production, low operation cost, good product quallity features, our spray dryer is welcomed by all home and aborad customers.

Features

Our PF resin spray dryer machine, which can instantly evaporate 95%-98% moisture of materials, is perfect for drying thermosensitive materials. Typically, the drying time is 5 to 15 seconds.

The dried products have the advantages of high purity, great fluidity and solubility.

This spray drying machine is simple to operate and eliminates the need for grinding and screening after drying.

Technical Specifications of Centrifugal Spray Drying Machine

|

Item/Model |

LPG |

|||||||||

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

|||||

|

Inlet temperature(℃) |

≤350 |

|||||||||

|

Outlet temperature (℃) |

80-90 |

|||||||||

|

Max. moisture evaporation (kg/h)* |

5 |

25 |

50 |

100 |

150 |

200-2000 |

||||

|

Drive type of centrifugal spray nozzle |

Compressed air drive |

Mechanical drive |

|||||

|

Rotation speed |

25000 |

22000 |

21500 |

18000 |

18000 |

15000 |

|

|

Diameter of spray disk(mm) |

50 |

102 |

108 |

108 |

150 |

180-340 |

|

|

Heat source |

Electricity |

Electricity |

Electricity |

Electricity + steam |

Electricity |

Depending on the user |

|

|

Max. electric heating power (kw) |

8 |

31.5 |

60 |

81 |

99 |

|

|

|

Outline dimensions L×W×H |

1.8×0.93×2.2 |

3×2.7×4.26 |

3.7×3.2×5.1 |

4.6×4.2×6 |

5.5×4.5×7 |

According to actual situation |

|

|

Dry powder recovery (%) |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

|

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Yanjialong Machinery Technology (Jiangsu) Co., Ltd.

- *Message:

-

Submit

Main Product:

MVR evaporator,

Low temperature evaporator,

Sludge dryer,

wastewater evaporator,

Power plant wastewater treatment,

spray dryer

You May Also Like