peristaltic pump aging test

11 month agoWhy can micro peristaltic pump be used in automatic cooking machines?

In the application of automatic cooking machines, the dc peristaltic pump can accurately control and deliver the liquid or seasoning required in the cooking process, such as oil, water, sauce, etc. Through preset programs and algorithms, the automatic cooking machine can control the operation of the micro peristaltic pump to ensure that the right amount of liquid or seasoning is accurately added at different stages of cooking, thereby improving the automation level of cooking and the quality of dishes.

How does the peristaltic pump work in an automatic cooking machine?

The micro dc peristaltic pump drives the pressure wheel or rotor on the pump head to rotate continuously through the motor. This rotational action causes the pump tube (usually a soft, compressible pipe) to produce periodic compression and relaxation under the action of the pressure point.

During the compression stage, the pump tube is compressed by the pressure wheel or rotor, so that a certain pressure is formed inside the pump tube. This pressure pushes the liquid (such as oil, water, sauce, etc.) in the pump tube forward. Because the pump tube is soft, it can be compressed and restored to its original shape without any valves or seals to prevent the backflow of the fluid.

When the pressure wheel or rotor moves to the next position of the pump tube, the previously compressed part will relax, allowing the pump tube to return to its original shape. At this time, new liquid is sucked into the pump tube to prepare for the next compression and push.

In the application of the automatic cooking machine, the micro peristaltic pump is connected to the control system of the cooking machine. The control system accurately controls the start, stop, rotation speed and working time of the peristaltic pump according to the preset cooking program. In this way, the peristaltic pump can add the right amount of liquid or seasoning at different stages of cooking according to the requirements of the program.

Technical Specification

| Voltage | DC12V | Current | 500mA |

| Power | 3.9W | Pressure | 80kpa |

| Flow | 12-18mlpm | Noise | 60db |

| Life span | more than 500 hours | Application | Vacuum cleaner,soap dispenser,cooking robot,cosmetic machine |

What are the advantages of using micro peristaltic pumps in automatic cooking machines?

1. Precise control: The micro peristaltic water pump has precise flow control capabilities, and can accurately add the required liquid or seasoning at different stages of cooking according to the requirements of the cooking program. This precise control not only improves the automation level of cooking, but also ensures the consistency of the taste and quality of the dishes.

2. Strong adaptability: The small dc peristaltic pump is able to handle liquids of various types and viscosities, including high viscosity, liquids containing large particles or easily corrosive. This means that it can adapt to different kinds of seasonings and cooking oils, allowing the automatic cooking machine to make more kinds of dishes.

3. Stable operation and reliability: The working principle of the peristaltic pump does not rely on seals or valves, which reduces the risk of failure and leakage. At the same time, its stable working performance also ensures the stability and reliability of the automatic cooking machine during long-term operation.

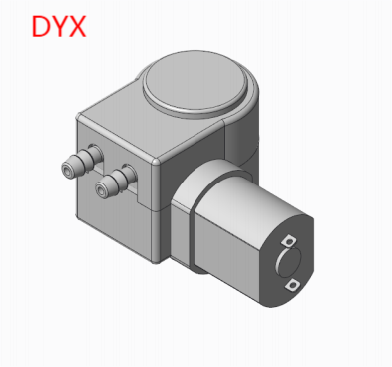

Dimension Drawing

How does a micro peristaltic dosing pump achieve precise flow control and metering functions?

First, the peristaltic pump achieves flow control by precisely controlling the speed of the pump head. There is a certain proportional relationship between the pump head speed and the flow rate, that is, the faster the speed, the greater the flow rate. Therefore, by adjusting the speed of the pump head, the liquid delivery volume can be precisely controlled. In practical applications, the appropriate pump head speed can be set according to the requirements of the cooking program to ensure that the right amount of liquid or seasoning is added at different stages of cooking.

Secondly, the precise metering function of the micro peristaltic pump mainly depends on the structure and material of its pump tube. As a channel for liquid delivery, the inner diameter and elastic properties of the pump tube have an important influence on flow metering. By selecting a pump tube with a suitable inner diameter and elastic modulus, the accuracy of flow metering can be improved to a certain extent. In addition, the length and bending degree of the pump tube may also affect the flow rate, so these factors need to be comprehensively considered in practical applications to optimize the accuracy of flow metering.

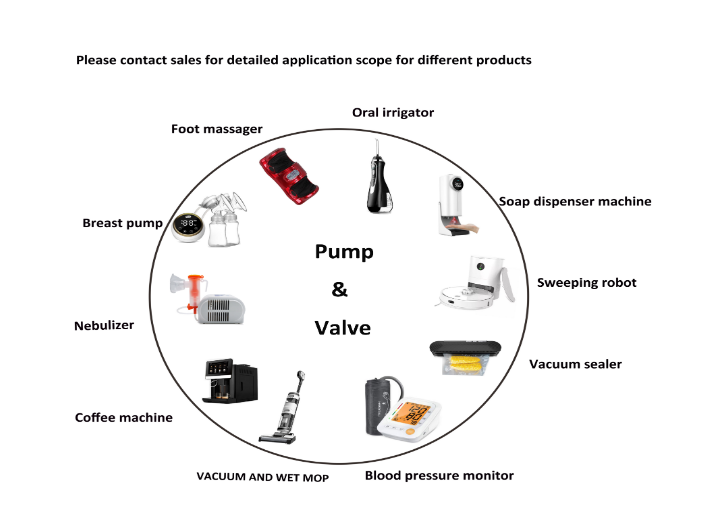

DYX Mini Pumps And Solenoid Valves Application

How does the pump tube of a dc electric peristaltic pump affect the accuracy of flow measurement?

First of all, the inner diameter of the pump tube directly determines the amount of fluid passing through. The larger the inner diameter, the more fluid passes through per unit time, and vice versa.

Therefore, the precise selection and control of the inner diameter of the pump tube is one of the keys to ensure the accuracy of flow measurement. If there is a deviation in the inner diameter of the pump tube, there will be an error between the actual flow rate and the set flow rate, which will affect the accuracy of flow measurement.

Secondly, the elastic properties of the pump tube will also affect the flow measurement. The working principle of the peristaltic pump is to push the fluid forward by periodically compressing and releasing the pump tube through the roller. Factors such as the elastic modulus, thickness, and material uniformity of the pump tube will affect its deformation degree and recovery ability when compressed. If the elastic properties of the pump tube are unstable or inconsistent, it will cause fluctuations and instability in the flow output, thereby affecting the measurement accuracy.

In addition, the long-term use and wear of the pump tube will also affect the flow measurement. As the use time increases, the inner wall of the pump tube may become rough or worn, which will increase the friction resistance of the fluid in the pump tube, resulting in a decrease in flow or increased fluctuations. Therefore, regular inspection and replacement of severely worn pump tubes is one of the important measures to maintain the flow measurement accuracy of micro peristaltic pumps.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen DYX Technology Co.,Limited

- *Message:

-

Submit

Main Product:

Mini Diaphragm Pump ,

Solenoid Pump,

Peristaltic Pump,

Piston Pump,

Solenoid Valve,

Solution For Mini Pumps And Valves

You May Also Like