Paper feed bridge

9 month ago

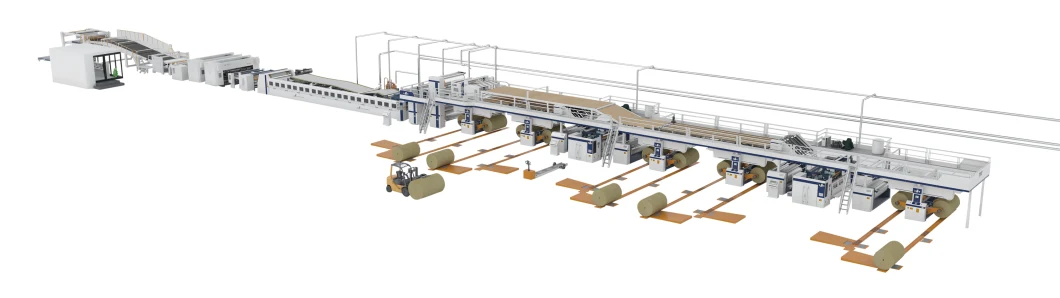

Corrugated Paper Board Making Machine

The original paper volume is sent to the reel frame, after heating and humidification, the original into the single-sided machine, after LT corrugated, another piece of original paper bonded into single-sided corrugated, and then through the conveyor. Bridge, multistage preheater reheating, gluing machine gluing, double-sided machine splicing, continuous corrugated board.

After cutting, cutting, crosscutting, produce different specifications of corrugated cardboard. Finally, the different sizes of corrugated cardboard are stacked, calculated, and delivered by a stacker.

A Complete Corrugating Board Production Line Includes The Following Machines:

Mill Roll Stand, Pre-Heater, Splicer, Single Facer, Over Bridge, Heavy Duty Drive, And Glue Machine, Double Facer,Slitter Scorer, Cutoff, Stacker, And Ect.

|

1,Maximum mechanical speed:300m/min |

|

2,Production line width:1400~2800mm |

|

3,Positive pressure cassette type quick roll change single face corrugator |

|

4,Double motor upper and lower independent drive double-sided machine |

|

5,Equipment high stability, low noise, long life |

|

6,High physical index and high speed of cardboard |

|

7,Energy saving of equipment, reducing unit energy consumption |

| 8,Easy to operate and maintain |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like