TL-ABS-403TL-ABS-403

9 month agoAdvantages of 3-4mm Thick ABS Sheets in Automotive Parts

Due to its unique features and versatility, the material has become a material of preference in the automotive industry. Overview of why ABS sheets are applied much in making automotive parts.

Impact Resistance

One of the most well-known features of the 3-4mm thick ABS sheet is its extremely high impact strength, making them highly recommended for use in the automotive industry where durability and strength are very critical. ABS won't crack or break under substantial impacts, securing the safety and longer lifespan of automobile parts.

Scratch Resistance

It has very high scratch resistance, which helps the sheet to keep its appearance for many years. This property is very useful for auto parts subject to frequent handling and abraded conditions, such as interior panels, dashboards, and exterior trims.

Antistatic Properties

The antistatic properties of ABS sheets keep the formation of static electricity at bay, hence preventing dust and dirt from sticking. This may become critical in automotive interiors where cleanliness is a prime requirement and static interference with the electronics has to be minimized.

Waterproof and Leak-Proof

Due to the impermeability of ABS sheets to water, they work perfectly for parts manufacturing that is exposed to moisture or potential leakage. This characteristic guarantees that automotive components will operate even in humid or wet environments and protects them from water damage, thus contributing towards vehicle reliability.

Corrosion Resistance

Besides, the waterproof properties, the ABS sheets show high resistance to many wide-range chemicals and corrosive materials. This resistance is very important for those vehicle parts that become exposed to very adverse conditions—for instance, motor parts and underbody parts, which normally face oils, fuels, and other chemicals.

Aging Resistance

The ABS sheets have very good durability against degradation with time, and they are very suitable for use in automotive parts. Due to their resistance against aging, the component will still maintain its integrity and performance after a long use.

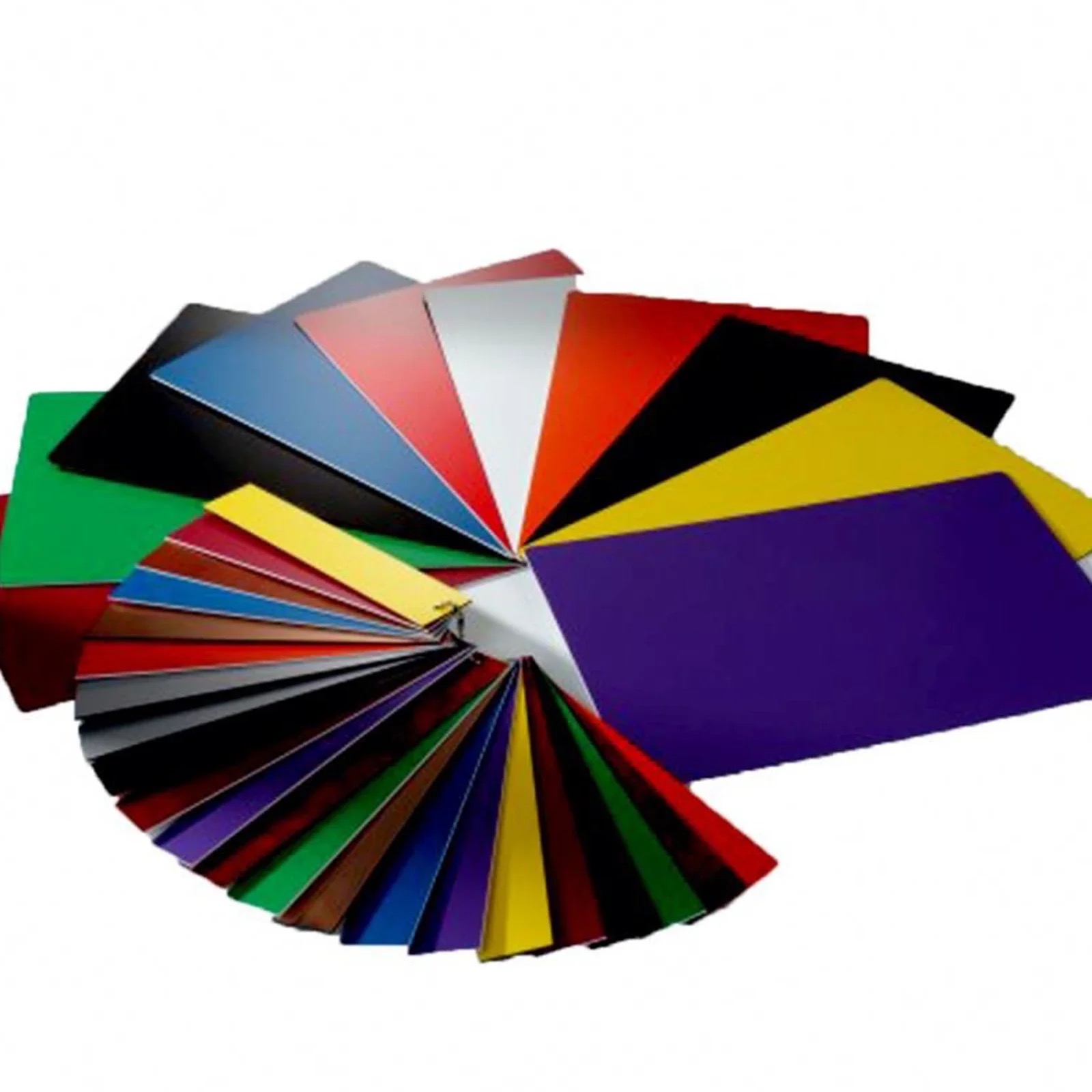

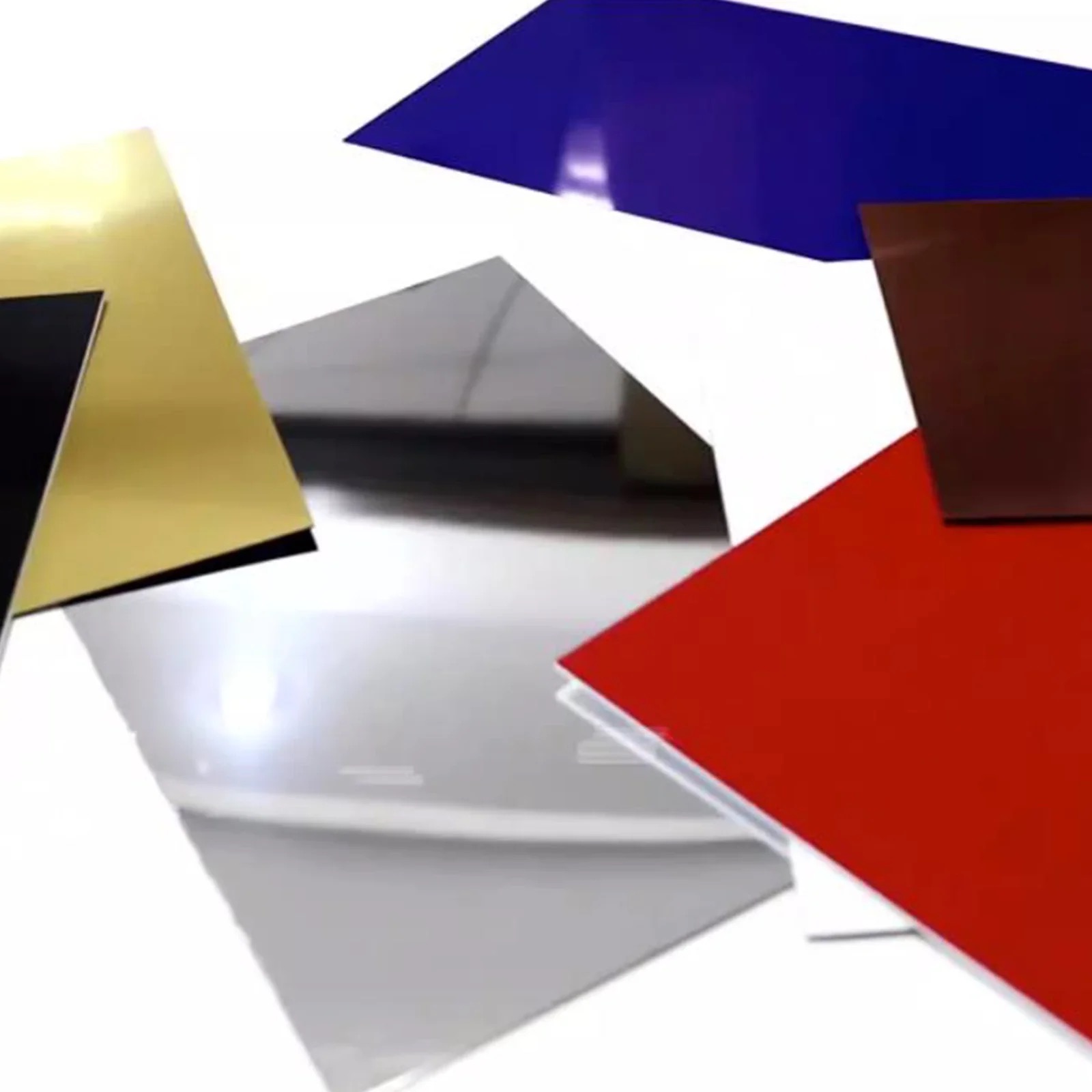

Customizable Finishes

One of the main advantages of ABS sheets is that they can be spray-painted in a variety of colors and finishes to allow aesthetic customization based on design and color scheme. Be it a glossy finish or matte or textured, ABS sheets could be tailored for specific designs.

High-Temperature Thermoforming

Thermoforming in high temperature can easily flex ABS sheets to be moulded into any complex shape and design that may be required by any part for automotive parts. This very property enhances the flexibility of ABS in manufacturing intricate and precise components which fit seamlessly into vehicle assemblies.

Conclusion

Additionally, the advantages of 3-4mm thick ABS sheets in automotive parts lie in the following features: high impact resistance, scratch resistance, antistatic properties, waterproof and leak-proof capabilities, corrosion resistance, aging resistance, customized finish, and easy high-temperature thermoforming. With such features, ABS is very essential for the manufacture of auto parts, hence ensuring strong, reliable, and beautiful products.

About us:

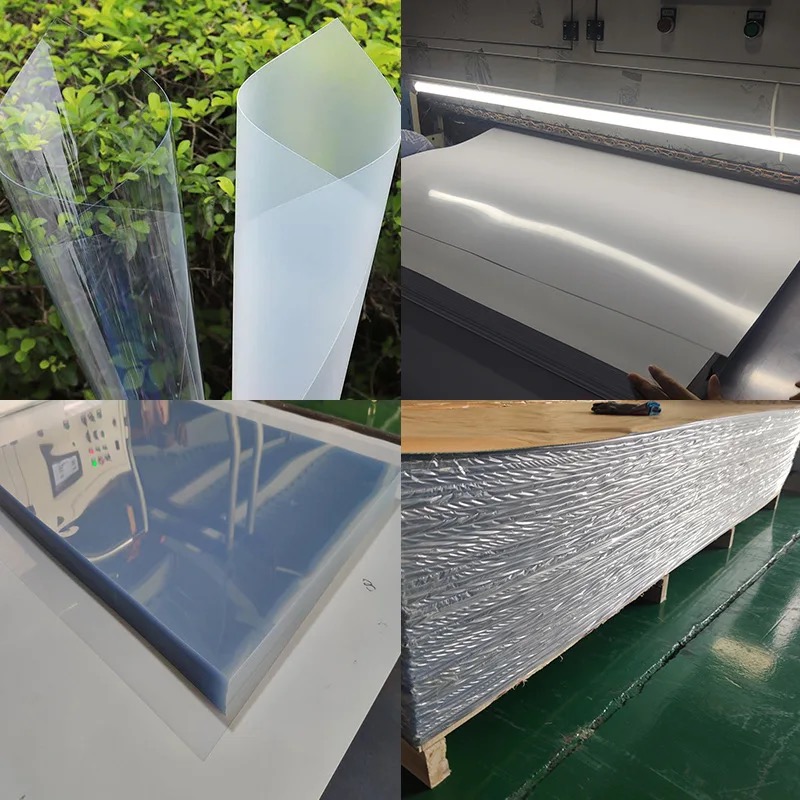

Shandong Top Leader Plastic packing Co.,Ltd was established in November, 1999. As a large-scale private enterprise with more than 500 staffs, our company is a major market player in plastic film and film manufacturer at North China. Our company pursues "people oriented policy" in human resource management and persists in applying "realistic approach, innovative mentality, quality consistency and efficient administration" as our core value. Strong technical force, advanced production equipment, our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply products of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane pressing film, etc. Totally 64 production lines, and the production of pvc sheet, PE sheet,pet sheet, Petg Sheet, GAG sheet, PP Sheet, PS Sheet, PC sheet ,pla sheet, Biodegradable material film and Composite Plastic Film widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging , Handicraft packaging and other fields.

All of our quality management is complied with ISO9001-2008 Quality Assurance Certificate and SGS Quality Assurance Certificate . We also apply "customer first, satisfaction service" to provide a comprehensive process service value on our products. As a result our products have covered all over the world market. We sincerely welcome customers and friends from home and abroad for exploration and instruction, to establish extensive cooperation and to create brilliant future together.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film ,

Other plastic packaging products

You May Also Like