TL-PP-301TL-PP-301

9 month ago

In the food industry, the safety and quality of packaging materials are paramount. Polypropylene (PP) sheets have become increasingly popular due to their unique combination of non-toxic, heat-resistant, and microwave-safe properties, making them ideal for various applications in food packaging and handling.

Non-Toxic Characteristics

One of the foremost concerns in food packaging is the potential for harmful substances to leach into food products. PP sheets are known for their non-toxic nature, ensuring that no harmful chemicals or additives are transferred to the food they encase. This characteristic makes PP sheets a preferred choice for packaging a wide range of food items, from fresh produce to processed foods, ensuring consumer safety and maintaining food quality.

Heat-Resistant Properties

The food industry often requires packaging materials that can withstand high temperatures during processes such as cooking, sterilization, and storage. PP sheets excel in this regard, offering exceptional heat resistance. They can endure temperatures up to 130°C (266°F), making them suitable for hot-fill processes and other high-temperature applications. This property not only preserves the integrity of the packaging but also ensures that the food remains uncontaminated and safe for consumption.

Microwave-Safe Advantages

In today’s fast-paced world, the convenience of microwaveable food packaging is highly valued. PP sheets are microwave-safe, allowing consumers to heat their food directly in the packaging without the risk of melting or releasing harmful substances. This convenience enhances the user experience, making meal preparation quicker and easier while ensuring that the packaging remains intact and safe to use.

Applications in the Food Industry

The versatile properties of PP sheets have led to their widespread adoption in various food industry applications:

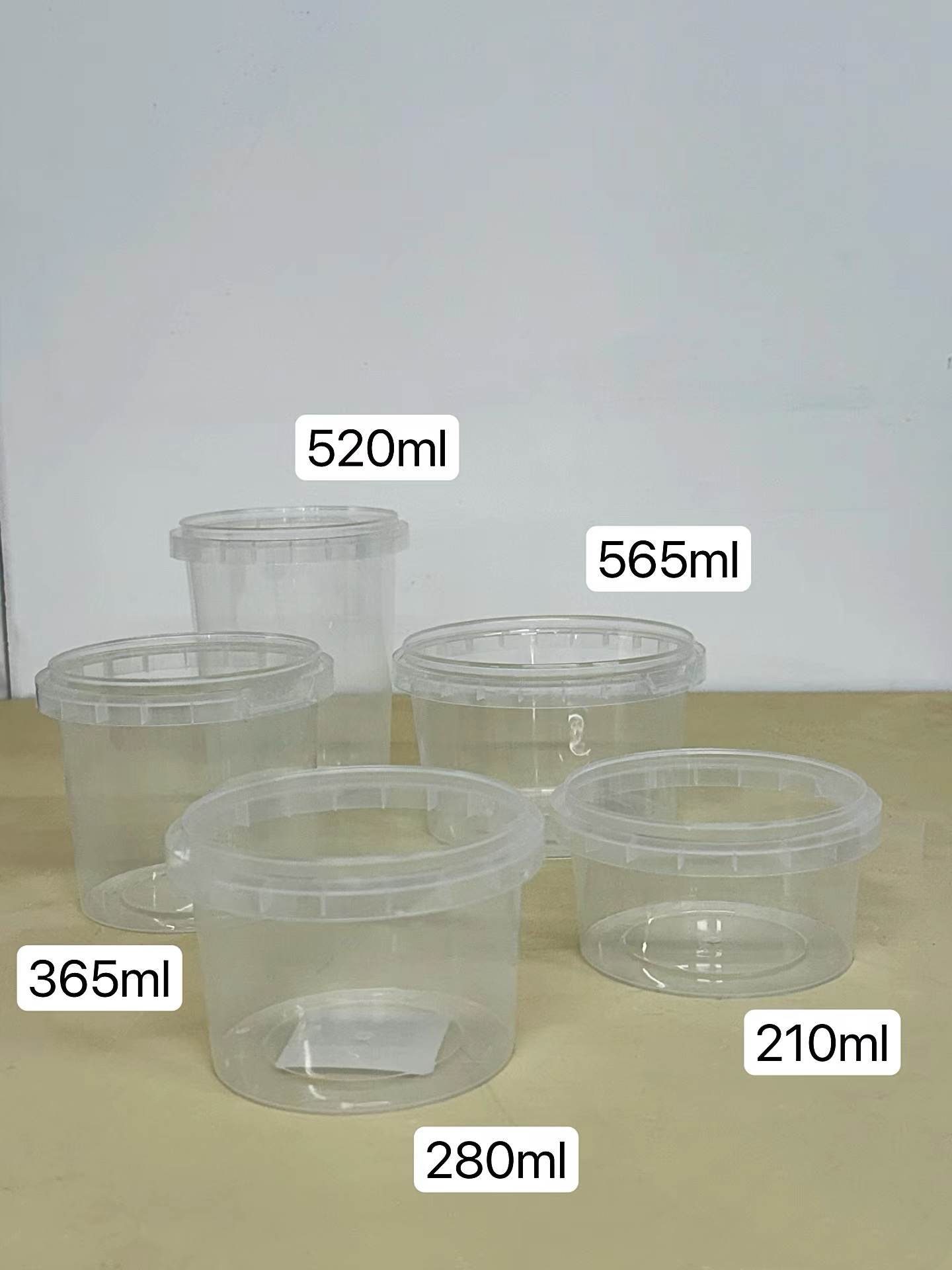

1. Food Containers: PP sheets are used to manufacture a variety of food containers, including those for ready-to-eat meals, takeout, and storage, ensuring they can be safely heated in a microwave.

2. Packaging Films: PP sheets are processed into films for wrapping fresh produce, meat, and dairy products, offering a non-toxic barrier that maintains food freshness and safety.

3. Disposable Tableware: Heat-resistant and microwave-safe PP sheets are used to produce disposable plates, bowls, and utensils, providing a safe and convenient option for both consumers and food service providers.

4. Baking and Cooking Trays: PP sheets are ideal for creating baking and cooking trays that can withstand high oven temperatures, making them a practical choice for both commercial and home kitchens.

Conclusion

Polypropylene (PP) sheets offer significant advantages in the food industry, including non-toxic properties, heat resistance, and microwave safety. These characteristics ensure that food products are packaged safely, heated conveniently, and stored securely, maintaining the highest standards of food safety and quality. As consumer demand for safe and convenient food packaging continues to grow, the role of PP sheets in the food industry is set to become even more vital.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film ,

PP Film,

Other plastic packaging products

You May Also Like