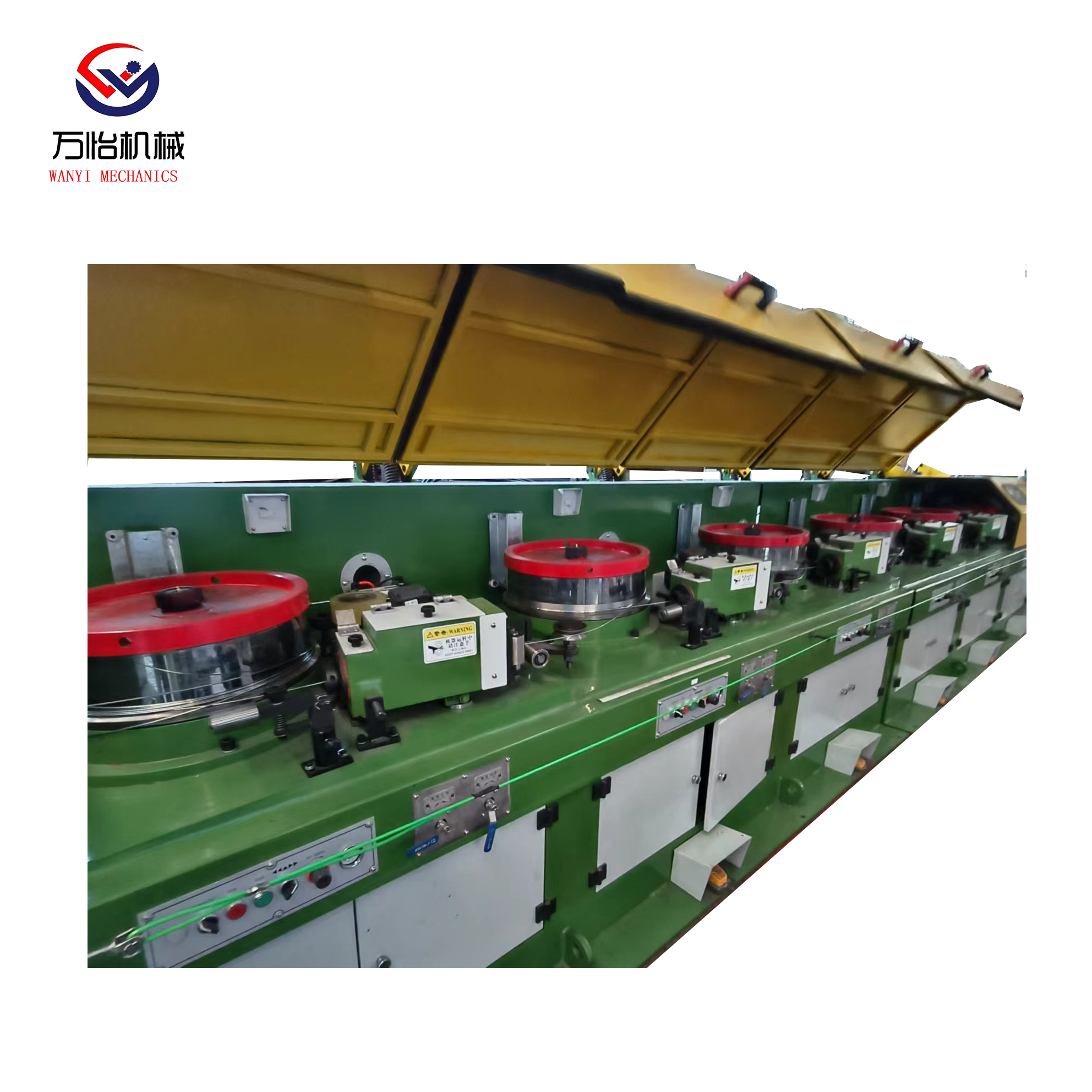

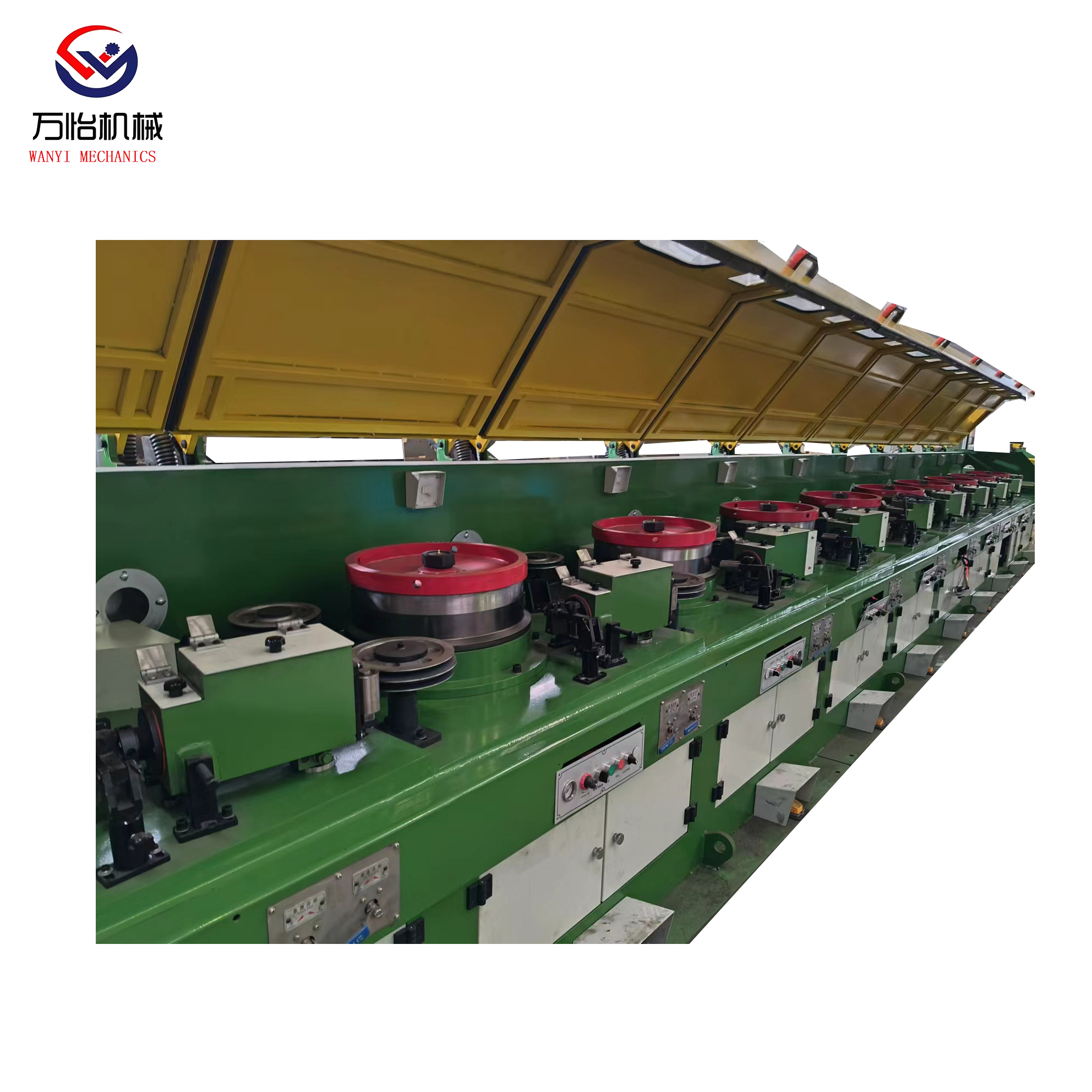

video-FCW drawing machine

8 month agoOn June 28, 1999, the State Administration of Machinery Industry released the current national standard JB/T 7910-1999 for wire drawing machines. This standard came into effect on January 1, 2000 and replaced JB/T 7910-95 with this standard. The national standard for wire drawing machines was first released in March 1989 as GB 10600-89 and was adjusted to JB/T 7910-95 in April 1996. The current national standard JB/T 7910-1999 for wire drawing machines specifies the types of wire drawing machines, basic parameters of wire drawing machines, technical requirements of wire drawing machines, testing methods of wire drawing machines, acceptance rules of wire drawing machines, marking, packaging, transportation and storage of wire drawing machines, and manufacturing guarantees of wire drawing machines.

■ High low-frequency torque and stable output wire drawing machine

High performance vector control

■ Good energy-saving effect

■ High precision proportional linkage control

■ Equipped with slip compensation function and high speed accuracy

Maintain constant tension and prevent wire breakage

Adopting the latest high-speed motor control dedicated chip DSP to ensure fast response of vector control

Modular design of hardware circuits ensures stable and efficient operation of the drawing machine frequency converter

The exterior design combines European automotive design concepts, with smooth lines and beautiful appearance

The structure adopts an independent air duct design, and the fan can be freely disassembled for good heat dissipation

No PG vector control, PG vector control, torque control, V/F control can all be selected

■ Powerful input and output multifunctional programmable terminals, speed regulation pulse input, two analog output channels

■ Unique "excavator" adaptive control feature, automatically limits the upper limit of motor torque during operation, effectively suppressing frequent overcurrent tripping

Wide voltage input, automatic voltage regulation (AVR) for output voltage, instant power failure without stopping, stronger adaptability

Built in advanced PID algorithm, fast response, strong adaptability, and easy debugging; 16 speed control, simple PLC implementation of timing, speed, orientation and other multifunctional logic control, multiple flexible control methods to meet various complex working conditions requirements

Built in international standard MODBUS RTU ASCII communication protocol, users can control the upper computer through PC/PLC to achieve centralized control of frequency converter 485 communication network

Stainless steel wire drawing machine

The main products include a complete set of wire drawing machines, which can pull large, medium, and small sizes from 6.5mm to 0.13mm; Stainless steel hydrogen annealing furnace and wire winding machine, wire drawing machine can pull from 8mm to 0.05mm. The drum and winding tank used for stainless steel are specially cast with white cast iron and other ingredients, with high hardness, wear resistance, and long service life. The galvanizing machine can coat 0.5-4mm iron wire onto the upper plate or main shaft, producing a flat and uniform shaft with the same degree of tightness. The straight wire machine can straighten 1.8-6.5 millimeters and is used for weaving nets, hardware construction, and other straight wire machines. The complete set of equipment for copper wire drawing machine can also be used to produce various wire mesh machinery, supporting products and accessories according to the user. Generally, the wire drawing machine is mainly driven by a wire laying motor, a wire winding motor and a wire arranging mechanism. As the wire winding diameter does not expand, the speed of the wire winding motor should be correspondingly reduced to ensure a constant wire speed. Tension feedback devices are often used in control to adjust the speed of the wire winding motor. With the continuous enhancement of frequency converter functions and stable performance, frequency converters have also been used in wire drawing machines. Among them, frequency converters are used to control the wire receiving and discharging motors, while the wire arranging motor is directly controlled by the grid voltage due to its low power. The working process of different wire drawing machines is basically the same.

We can make wire drawing machine,drum packing machine,layer winding machine and butt welding machine,

pointing machine and so on.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jiangyin Wanyi Machinery CO.,Ltd

- *Message:

-

Submit

Main Product:

Wire Drawing Machine ,

Flux Cored Wire Forming Machine ,

Layer Winding Machine ,

Mig Welding Wire Production Machine ,

pay off and take up machinery,

drum packing machine

You May Also Like