b385fc10e9456e7495c75df0dcc8c45c

8 month agoHello, friend, we are professional tungsten steel (hard alloy) mold manufacturers.

Looking forward to our cooperation and solving your needs!

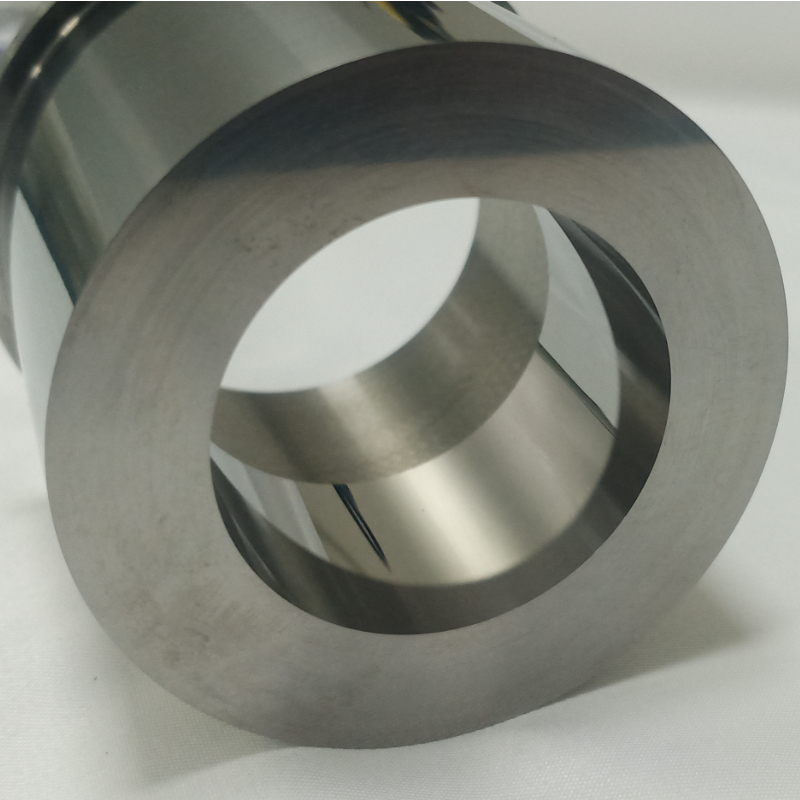

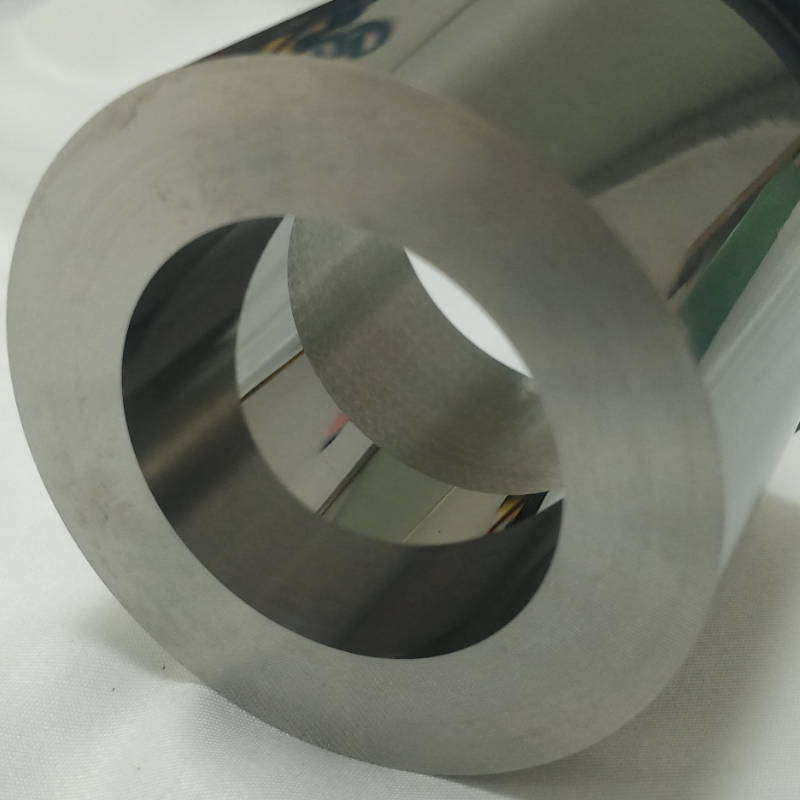

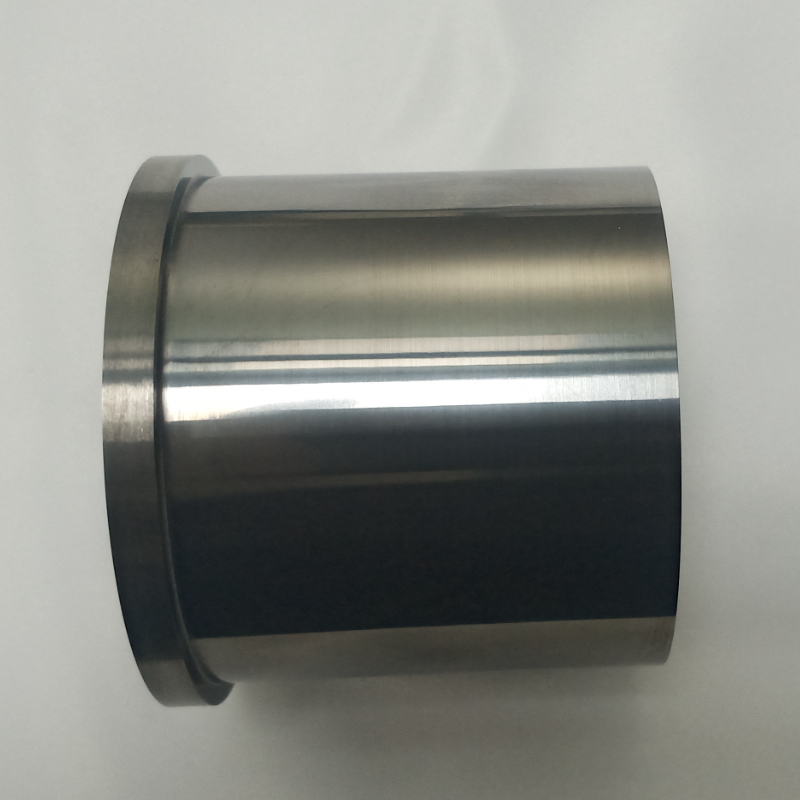

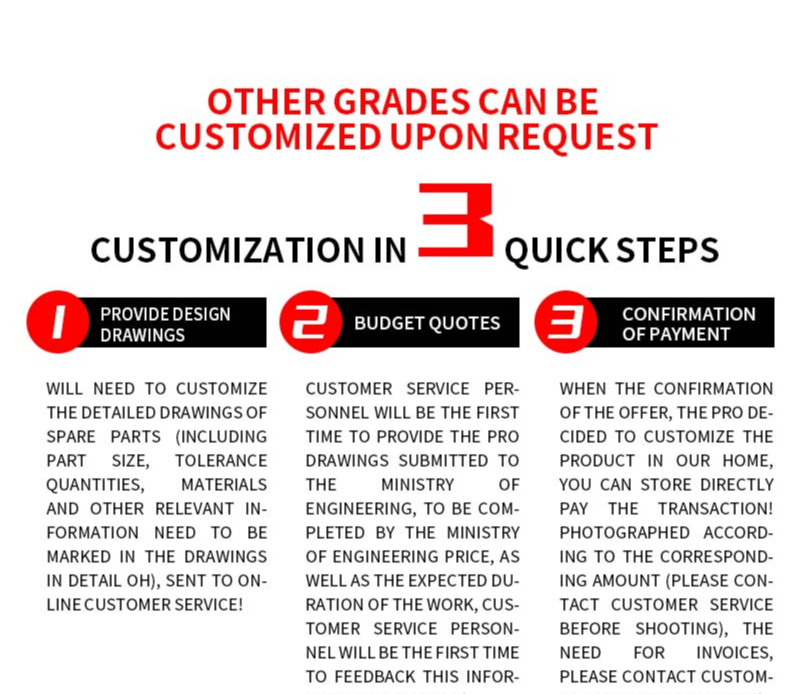

Dongguan Fengguan Precision Technology Co., Ltd. is located in Changan Town, Dongguan City, which is the main center of Zhuzhou cemented carbide in Dongguan. The main tungsten carbide materials, tungsten steel mold deep processing and all kinds of tungsten steel precision accessories. The cemented carbide series mainly produced and sold are: cemented carbide tungsten steel plate, cemented carbide tungsten steel round rod, cemented carbide tungsten steel strip, cemented carbide tungsten steel round die, diamond tungsten steel, various kinds of cemented carbide tungsten steel non-standard blank, non-magnetic tungsten steel, hard alloy drawing die, tungsten steel pipe shrinking die, tungsten steel pipe drawing die, tungsten steel forming die, tungsten steel punching die, powder metallurgy die, tungsten steel sealing die, Tungsten steel insert sleeve, Tungsten steel extrusion die, Tungsten steel roll, Tungsten steel guide rail, Tungsten steel sealing ring, Tungsten steel punching and shearing die, Tungsten carbide wear-resistant parts, Tungsten wear-resistant steel, Tungsten corrosion-resistant steel, Tungsten steel conductive block, Tungsten steel punch, Tungsten steel bushing, Tungsten steel parts, cemented carbide ball, Tungsten steel milling cutter, diamond blade, Tungsten steel processing, etc. The main products are: Tungsten Steel Stretching Mold,CNC Processing Tungsten Steel Products,Tungsten Steel Die Material,Tungsten Carbide Custom Machining,Tungsten Steel Precision Machined Parts,New Energy Materials Ceramic Aluminium Oxide Zirconia。

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Fengguan Precision Technology Co., Ltd.

- *Message:

-

Submit

Main Product:

Tungsten steel irregular die,

Tungsten steel strip,

Tungsten steel plate ,

Tungsten steel round die,

Tungsten steel drawing die,

Customization of non-standard parts of tungsten steel

You May Also Like