Integrated machine (injection machine +feeder)

8 month agoOur factory is professional in manufacturing the liquid silicone injection molding machine (LSR molding machine /Injection machine of LSR),from 35T,55T,85T,120T,160T & 200T,Horizontal injection molding machine and vertical LSR injection machine we have.Together with liquid silicone mold and automation for your choosing.We also make the plastic injection molding machine and rotary plastic injection mold machine .

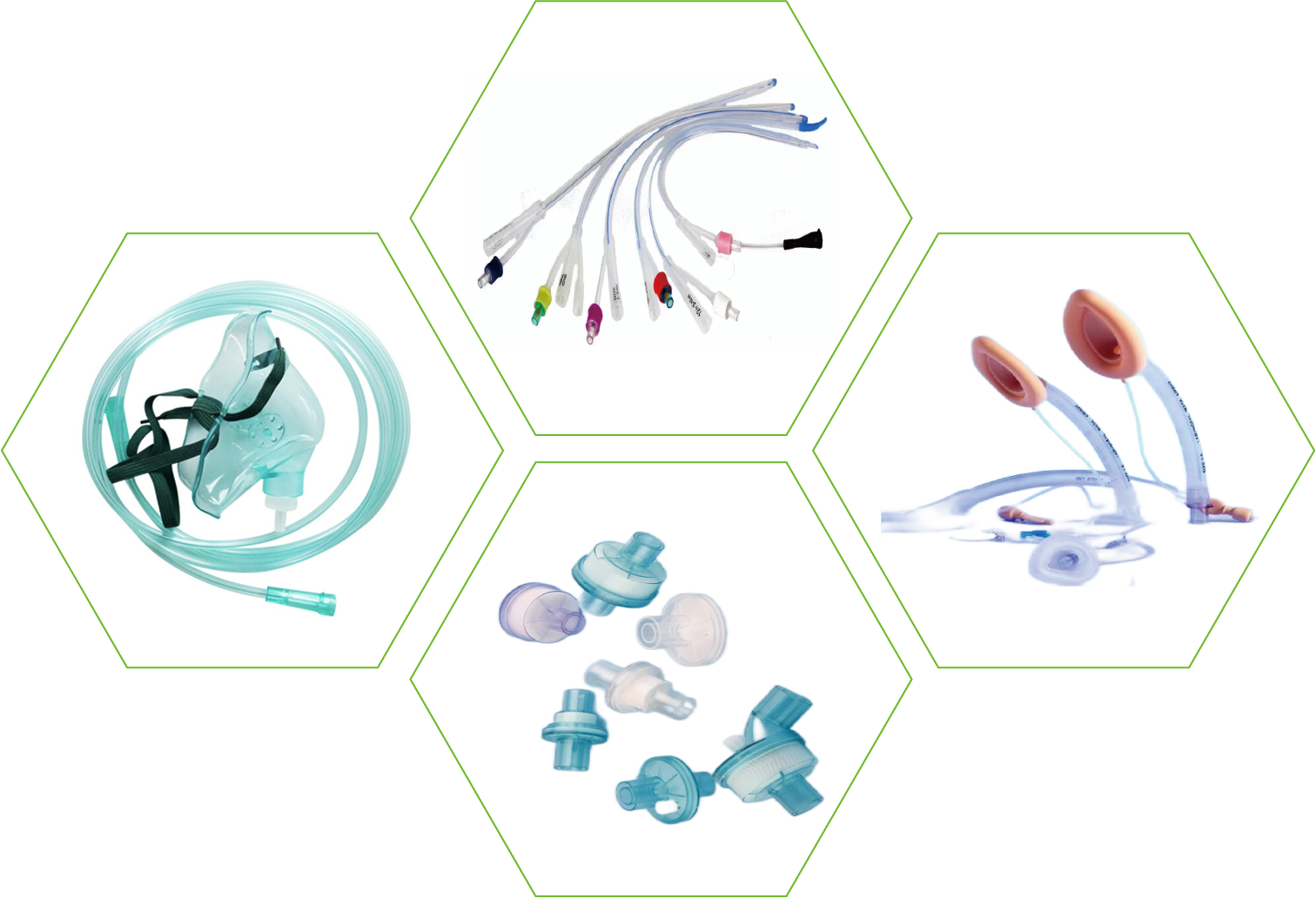

Silicone products are more and more popular nowadays.including solid silicone and liquid silicone .Solid silicone products are made by compressing machine;liquid silicone products are made by the liquid silicone rubber molding machine.

Vertical dosing unit is used for making the liquid silicone rubber product.And it works with the liquid silicone rubber injection molding machine and LSR mold.It is also called feeding machine.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangzhou S-guangyu Machinery &Equipment Co.,Ltd

- *Message:

-

Submit

Main Product:

Liquid silicone rubber injection molding machine,

Lsr injection molding machine ,

Vertical Injection machine,

liquid silicone injection molding machine,

Silicone injection molding machine,

Injection moulding machine

You May Also Like