bopet printable packaing

5 month agoUnveiling Creativity and Functionality:

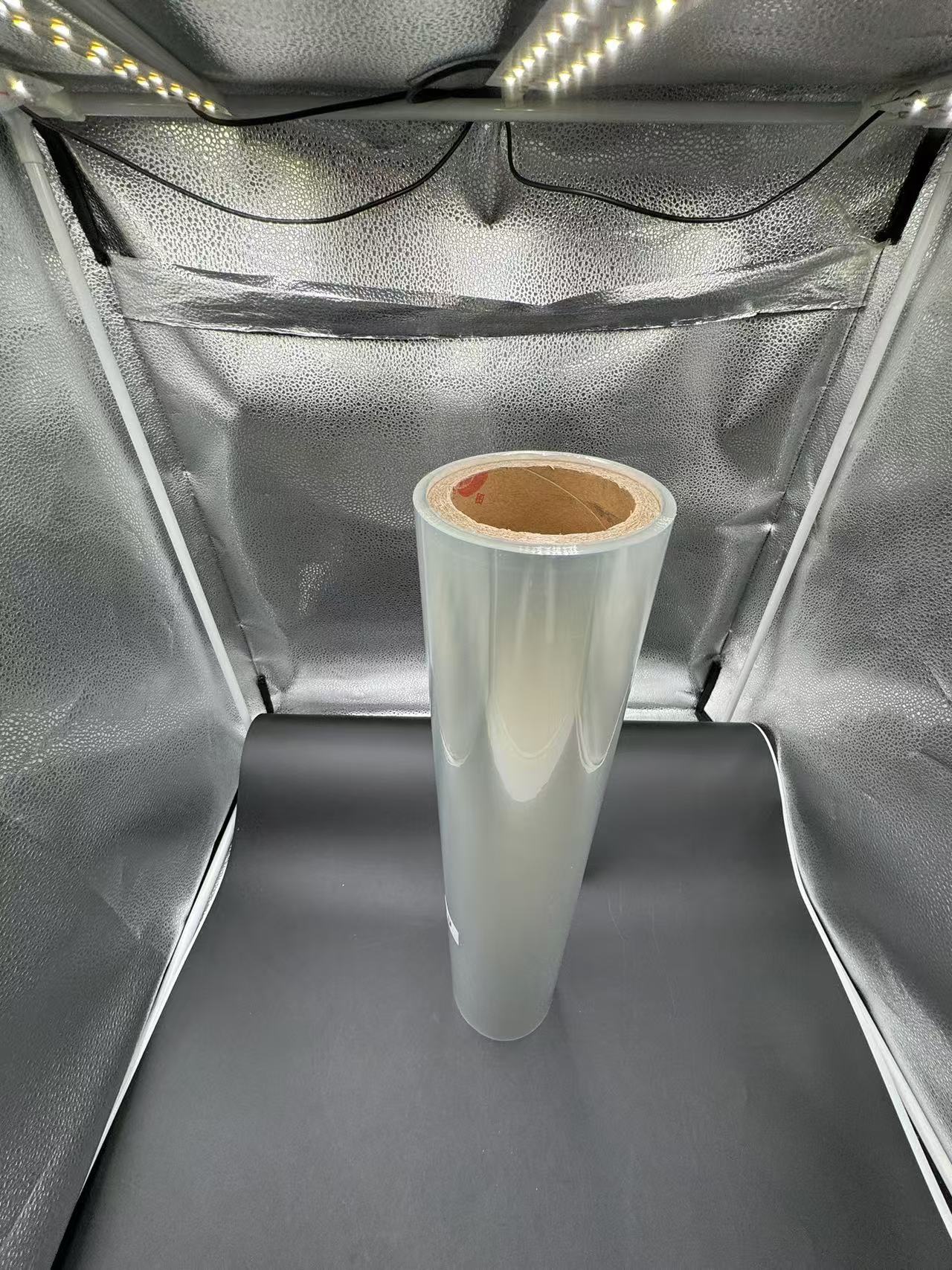

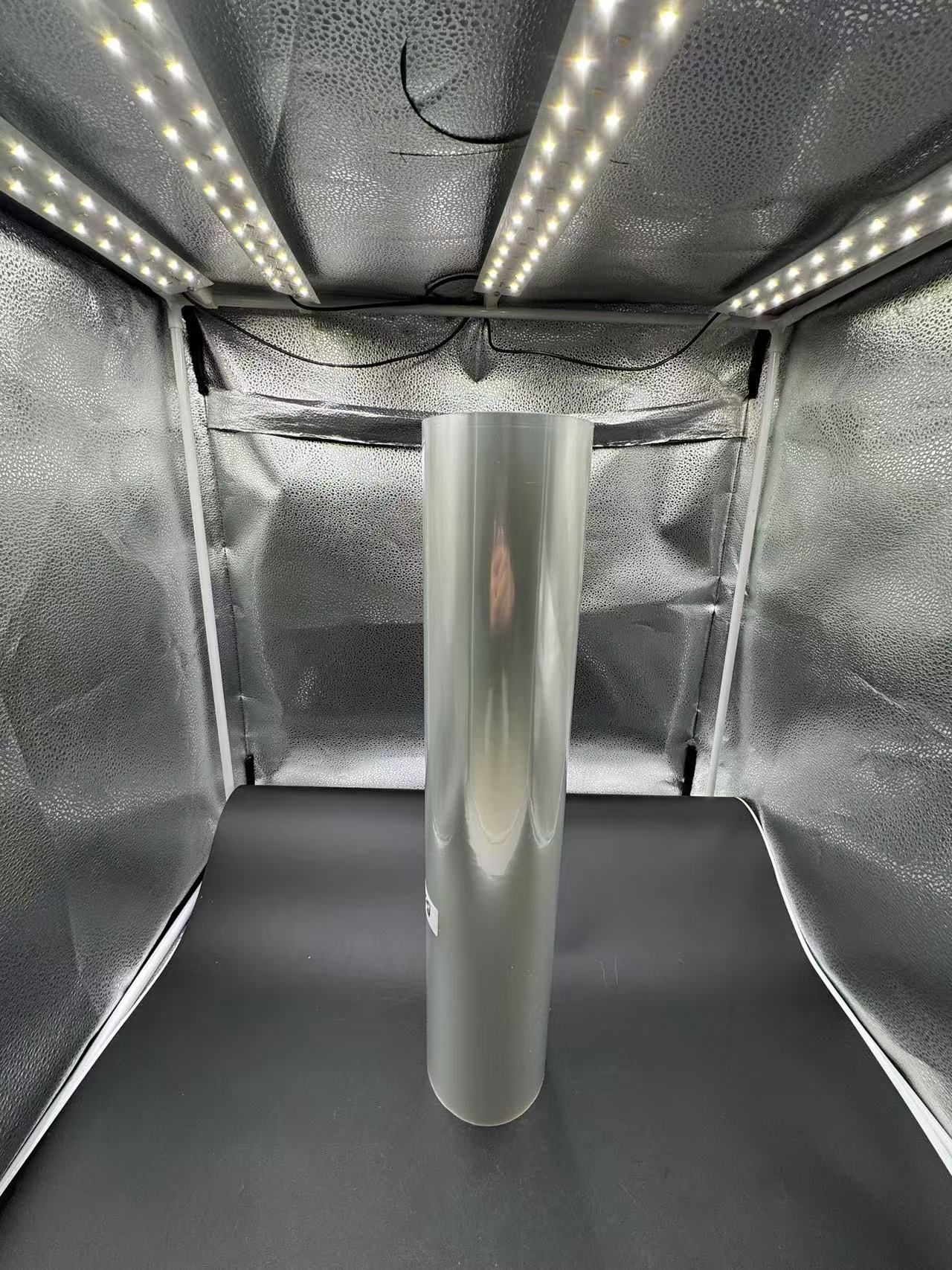

The Diverse Application of Transparent BOPET Printable Film in Packaging Introduction Materials play a major role in deciding the fate of a product's market

Transparency and Clarity

Probably the most striking feature of the transparent BOPET printable film is the high level of transparency and clarity. It allows a full, unobstructed view of the contents it covers, which is of immense importance in packaging applications where the product has to be

This printability not only serves the purpose of conveying essential information to consumers but also plays a crucial role in creating a distinct brand identity, making products stand out on crowded store shelves.

Mechanical Properties

BOPET printable film exhibits impressive mechanical strength due to its biaxial orientation. It has a high tensile strength, enabling it to withstand significant stretching and pulling forces without tearing or deforming easily. This strength is paramount at the time of the manufacture of the film-for its conversion into bags and inclusion in composite films-against their mechanical stresses. Since this material is flexible and ductile, it follows easily the shapes and geometries, whether it tourns irregularly shaped food merchandise or is molded into certain specific geometries for particular forms of packaging. It also possesses excellent puncture resistance, which can protect the packaged products against any accidental external damage during handling and transportation due to sharp objects.

Barrier Properties

Barrier Properties

Transparent BOPET printable film possesses excellent barrier properties for protecting the packaged goods. It serves as a perfect barrier against moisture, gases such as oxygen and carbon dioxide, and odor. In the food packaging domain, it helps maintain the freshness and quality of products by preventing the ingress of moisture that could lead to spoilage and by restricting the entry of oxygen that causes oxidation and degradation. For example, in the case of a bag of potato chips, the film keeps the chips crispy by keeping moisture out and slows down rancidity by limiting oxygen exposure. In the pharmaceutical and cosmetic fields, it protects sensitive products against environmental factors that would have an impact on the efficacy and stability of pharmaceuticals, maintaining the potency of medications and the integrity of cosmetics.

Heat Resistance

that undergo pasteurization or sterilization at comparably low temperatures. After orientation and surface treatment, the film undergoes an annealing process to relieve the internal stresses generated during stretching. Annealing involves heating the film to a specific temperature below its melting point and then slowly cooling it. It contributes to the stabilization of the film's molecular structure, ensuring its dimensional stability, consequently preventing its warping or cracking while undergoing further handling and service. After that, it cools down to room temperature and is wound on jumbo rolls, which later head to various packaging manufacturers across industries.

that undergo pasteurization or sterilization at comparably low temperatures. After orientation and surface treatment, the film undergoes an annealing process to relieve the internal stresses generated during stretching. Annealing involves heating the film to a specific temperature below its melting point and then slowly cooling it. It contributes to the stabilization of the film's molecular structure, ensuring its dimensional stability, consequently preventing its warping or cracking while undergoing further handling and service. After that, it cools down to room temperature and is wound on jumbo rolls, which later head to various packaging manufacturers across industries.

Quality Control

Severe quality control measures have to be in place at all times during the manufacturing process. The thickness of the film is gauged with highly accurate instruments to ensure that it meets the specified standards since any deviation will affect performance in packaging applications. Other key properties, such as transparency, mechanical strength, barrier properties, printability, and heat resistance, are also tested comprehensively in the laboratory. Any film that does not pass the high-quality threshold standards is discarded to ensure only high-quality transparent BOPET printable film reaches the market for use in critical packaging.

Applications of Transparent BOPET Printable Film in Printable Packaging

Food Packaging

The food industry uses transparent BOPET printable

Cosmetic Packaging

Cosmetics rely heavily on packaging that is both visually appealing and informative. Transparent BOPET printable film fits the bill perfectly. Sleevings or wraps for color display in lipstick, mascaras, and eyeshadows

Cosmetics rely heavily on packaging that is both visually appealing and informative. Transparent BOPET printable film fits the bill perfectly. Sleevings or wraps for color display in lipstick, mascaras, and eyeshadows

with improved properties. For example, it is laminated with aluminum foil in order to improve light, oxygen,

with improved properties. For example, it is laminated with aluminum foil in order to improve light, oxygen,

Benefits of Using Transparent BOPET Printable Film in Packaging

Benefits of Using Transparent BOPET Printable Film in Packaging

Visual Appeal and Branding

High transparency and excellent printability make the film offer a package that is beautiful to look at and highly effective for brand messages. Products have a commanding presence on the store shelf as consumers are clearly able to see what the contents are, and good, well-designed prints are done on them. This gives rise to brand recognition and brand loyalty, since consumers relate an attractive package to quality merchandise.

Product Protection

Recyclability

Recyclability

BOPET is a recyclable material, which is a great advantage in today's world that is conscious of environmental protection. After use, the film can be collected, recycled, and reprocessed into new products, thus reducing waste and conserving resources. This recyclability makes BOPET printable film an appealing choice for both consumers and manufacturers who are committed to sustainable packaging practices.

Challenges and Solutions in the Use of Transparent BOPET Printable Film in Packaging

Challenges and Solutions in the Use of Transparent BOPET Printable Film in Packaging

Printing and Ink Compatibility

While the film has good printability, ensuring compatibility with different inks and printing techniques can be a challenge. Some inks may not adhere well or may fade over time. Manufacturers should, therefore, conduct thorough ink compatibility tests before production, selecting inks that are specifically designed for plastic films and have good adhesion and lightfastness properties. Surface treatments like corona or plasma treatment can also be optimized to enhance ink adhesion.

Adhesion and Lamination Issues

Heat Sealability and Compatibility with Filling Processes

Heat Sealability and Compatibility with Filling Processes

In some cases, this can be a problem for consistent and reliable heat sealability of BOPET printable film when used with certain filling processes. This is where the manufacturer would need to invest time in testing to identify the optimal heat seal parameters for any given application. They can also work with equipment suppliers to ensure that the packaging machinery is compatible with the film's heat seal requirements. Additionally, using additives or modifying the film's composition can improve its heat sealability.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film ,

Other plastic packaging products

You May Also Like