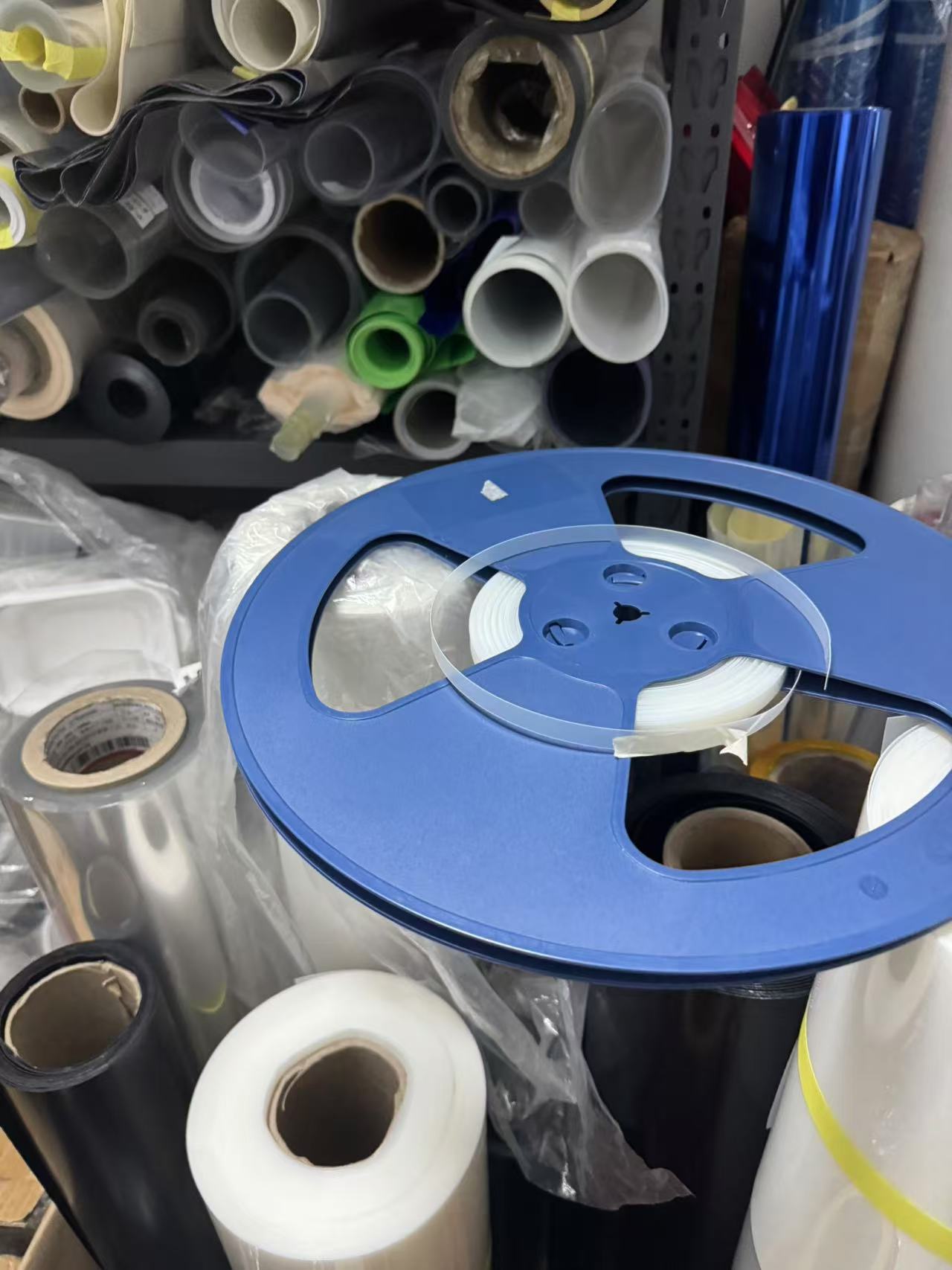

electronic component carrier

5 month agoPET Grid Film: The Versatile Solution for Electronic Component Carriers

I. Introduction

A. What is PET Grid Film?

II. Properties of PET Grid Film

A. High Transparency

A prominent characteristic of PET grid film is its remarkable transparency. This enables effortless visual inspection of the electronic components placed atop or beneath it. During production, technicians can promptly assess the alignment, integrity, and any potential flaws of the components without the need to remove the film.

B. Good Electrical Insulation

PET grid film exhibits excellent electrical insulation capabilities. In an electronic device, where numerous components with varying electrical potentials are in close proximity,

C. Durability

The durability of PET grid film is another crucial aspect that renders it highly suitable for electronic component carriers. It can endure a gamut of environmental conditions, including temperature fluctuations, humidity, and mechanical stresses. In the manufacturing environment, components are frequently subjected to handling, transportation, and assembly procedures that could potentially damage them. The PET grid film serves as a protective shield, diminishing the risk of scratches, abrasions, and breakages. Moreover, throughout the lifespan of an electronic device, it can withstand the typical wear and tear, ensuring the continued safeguarding of the components. For example, in portable electronic devices like smartphones and tablets, which are constantly in motion and exposed to diverse conditions, the PET grid film contributes to maintaining the integrity of the internal components.

III. Uses of PET Grid Film in Electronic Component Carriers

A. Protection of Electronic Components

IV. Advantages of PET Grid Film in Electronic Component Carriers

A. Cost-Effective

C. Easy to Process

Another advantage of PET grid film is its ease of processing. It can be readily cut, shaped, and laminated using standard manufacturing techniques. This flexibility empowers manufacturers to customize the film according to their specific requirements. For example, they can trim the film into diverse shapes and sizes to fit the exact dimensions of the component carrier they are designing. Lamination can be employed to combine the PET grid film with other materials, such as adhesives or protective coatings, to further enhance its properties. This ease of processing facilitates efficient production lines and rapid turnaround times, which are vital in the fast-paced electronics industry.

VI. Applications of Electronic Component Carriers with PET Grid Film

A. Consumer Electronics

B. Automotive Electronics

C. Industrial Electronics

VIII. Conclusion

A. Summary of Key Points

B. Future Prospects

Looking forward, the future prospects of PET grid film in electronic component carriers are auspicious.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film ,

PC Film,

PP Film,

Other plastic packaging products

You May Also Like