TL-NONPVC-707TL-NONPVC-707

6 month agoIntroduction

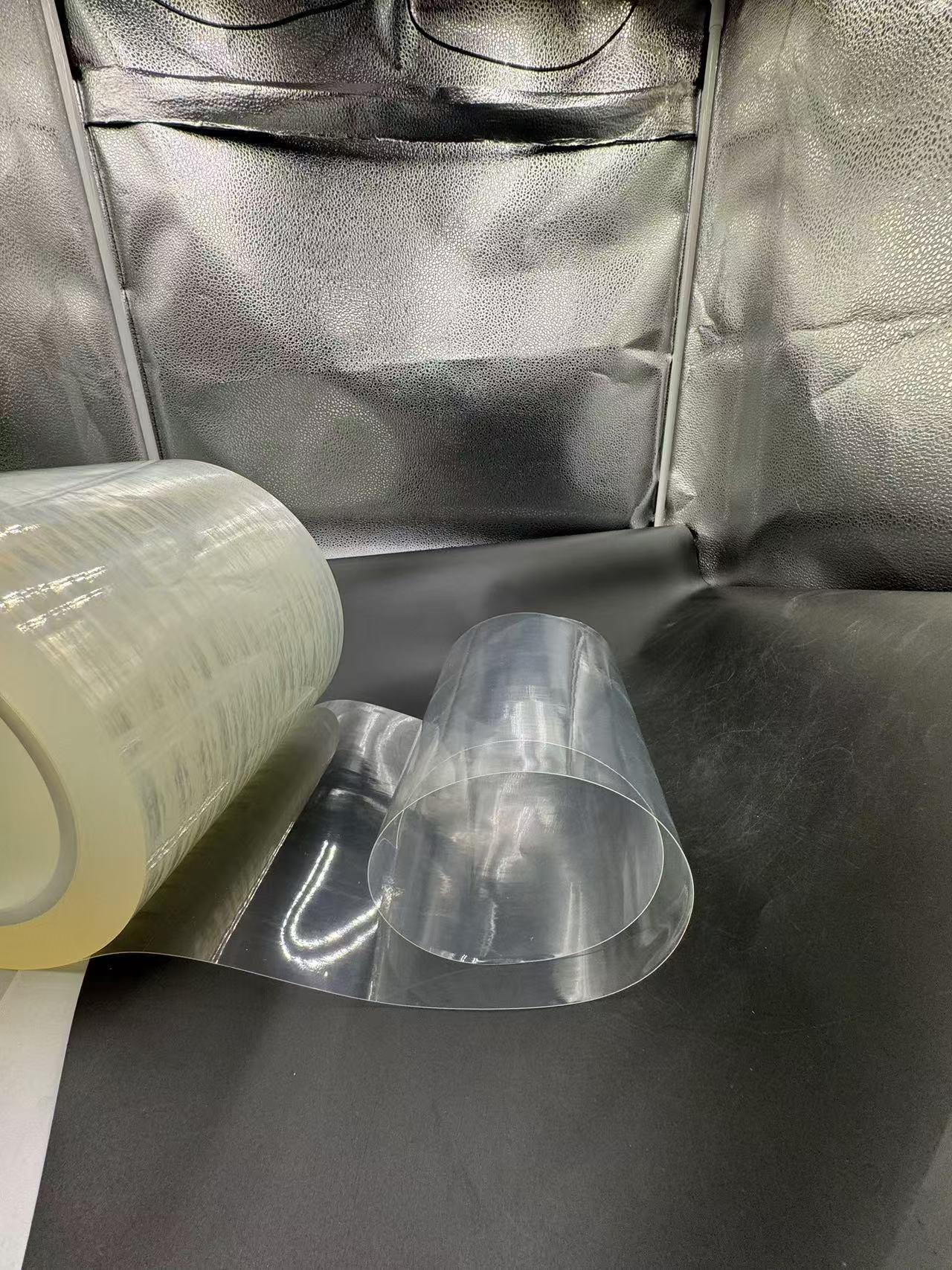

In the ever-evolving landscape of medical packaging, the shift towards materials that offer both performance and safety has led to an increased interest in NON-PVC transparent films. These films, while sharing some properties with traditional PVC,

provide distinct advantages that make them particularly appealing for use in healthcare and pharmaceutical industries. This article delves into the characteristics of NON-PVC transparent films, highlighting their applications in medical packaging, and providing a detailed analysis based on current industry practices and standards.

Characteristics of NON-PVC Transparent Film

1. High Transparency

NON-PVC transparent films are renowned for their optical clarity. This characteristic allows for easy visual inspection of the contents of packaging, which is crucial in medical applications where the integrity and condition of medicines or medical devices need to be verified without breaking the seal. The transparency ensures that any changes in the product, such as discoloration or degradation, can be noticed immediately, promoting safety and efficacy.

2. Barrier Properties

One of the primary reasons for adopting NON-PVC films in medical packaging is their superior barrier properties against moisture, oxygen, and UV light. Unlike PVC, which might require additional coatings or laminations for similar protection, NON-PVC films naturally exhibit these properties. These films protect sensitive pharmaceuticals from environmental factors that could compromise their stability or effectiveness.

3. Flexibility and Durability

NON-PVC films often provide a balance between flexibility and rigidity, making them suitable for various packaging methods like thermoforming or blister packaging. They can be molded into complex shapes without compromising the structural integrity, which is essential for packaging different sizes and shapes of medical devices or pharmaceuticals. Moreover, these films resist punctures and tears better than some traditional materials, ensuring product safety during handling and transport.

4. Chemical Stability

These films are chosen for their chemical inertness, particularly in environments where they might be exposed to drugs, disinfectants, or other chemicals used in healthcare settings. This stability minimizes the risk of chemical interactions that could affect the medication or contaminate the environment.

5. Environmental and Health Considerations

Unlike PVC, which has been criticized for its environmental impact due to the release of toxic fumes during manufacturing and disposal, NON-PVC films are generally more environmentally friendly. They often do not contain plasticizers like DEHP, which have raised health concerns, particularly in medical environments where patient safety is paramount.

Usage in Medical Packaging

Blister Packaging

Blister packs are a common application for NON-PVC films due to their excellent thermoformability, providing a secure and visible enclosure for tablets, capsules, and medical devices. The film's durability ensures that each compartment remains intact, preventing accidental exposure to air or contaminants.

Case Study: Pharmaceutical Tablets

In packaging for tablets, the clarity of NON-PVC films allows for consumer confidence in product verification at the point of sale. The barrier properties keep the tablets in optimal conditions, extending shelf life and maintaining potency.

Medical Device Packaging

For medical devices, particularly those that are sterile or sensitive to environmental changes, NON-PVC films offer an excellent protective layer. The films can be used in packaging for syringes, catheters, and diagnostic tools where sterility and material integrity are critical.

Case Study: Sterile Packaging

The use of NON-PVC films in sterile packaging for surgical instruments illustrates how these materials maintain the sterile barrier while allowing for easy access when needed. Their resistance to UV radiation ensures that the materials inside are not degraded by light exposure.

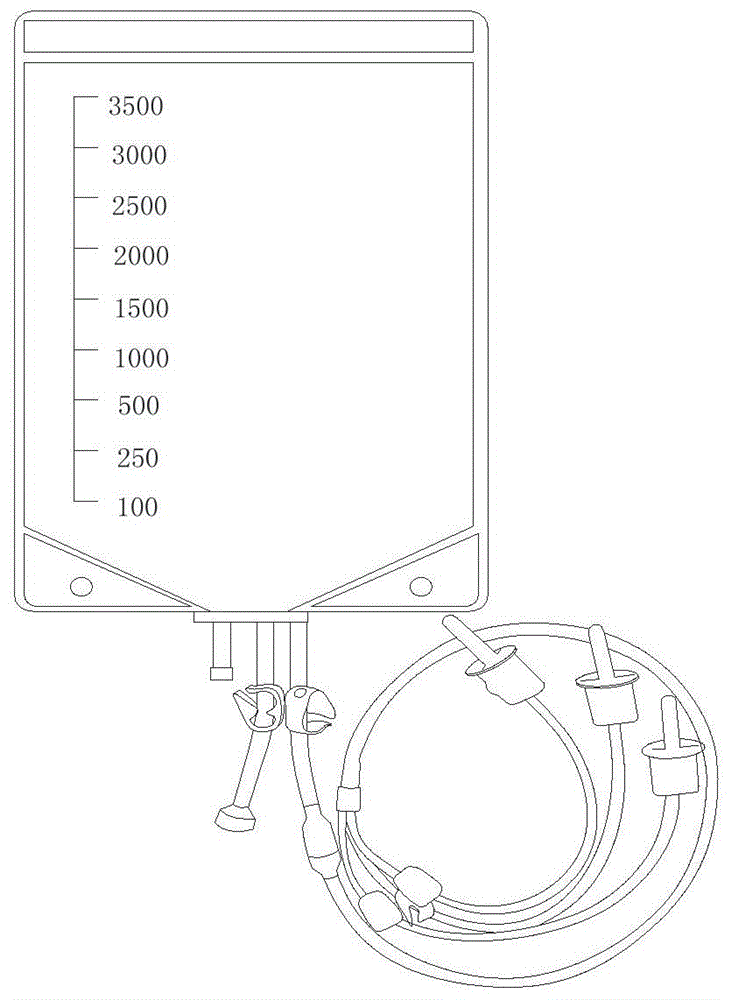

IV Bags and Fluid Containers

While PVC has been traditionally used for IV bags due to its flexibility, NON-PVC alternatives are gaining ground. These films offer similar flexibility without the need for potentially harmful plasticizers, thus enhancing patient safety, especially in pediatric and neonatal care where chemical exposure can be more significant.

Compliance with Regulations

NON-PVC films often meet or exceed the stringent regulations set by bodies like the FDA or the European Commission for medical packaging. Their compliance with standards for direct contact with pharmaceuticals makes them a preferred choice in regulated environments.

Conclusion

The adoption of NON-PVC transparent films in medical packaging represents a significant advancement in ensuring product safety, environmental responsibility, and patient health. With their unique combination of transparency, durability, and barrier properties, these films are not just alternatives but often superior choices for modern medical packaging needs. As the industry continues to move towards more sustainable and safe material options, NON-PVC transparent films will likely play a pivotal role in shaping the future of pharmaceutical and medical device packaging.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film ,

Other plastic packaging products

You May Also Like