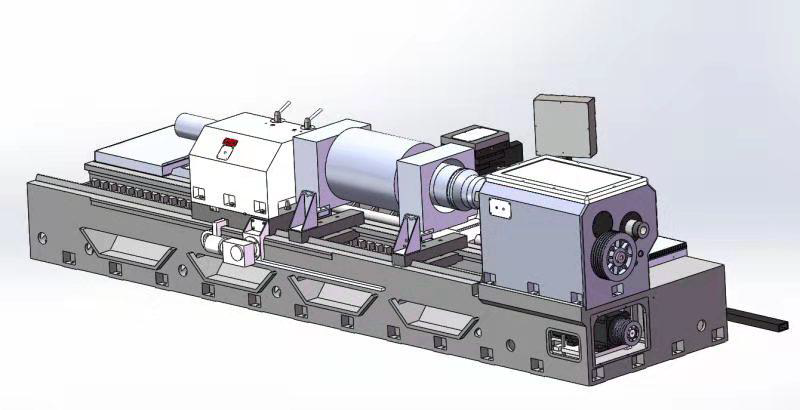

CK8480 CNC roll turning lathe

6 month ago

| Maximum machining diameter | Φ880mm |

| Workpiece length | 500mm~3500mm |

| Spindle speed | 1rpm~200rpm |

| Spindle center height | 1320mm |

| Spindle motor power | 45KW |

| Z-axis motor power | 5.2KW |

| X-axis motor power | 3.0KW |

| Z-axis feed speed range | 1~3000mm/min |

| X-axis feed speed range | 1~2000mm/min |

| Distance from spindle center to guide rail | 580mm |

| Distance from spindle center to tailstock center | 3500mm |

| Distance from spindle center to carriage | 470mm |

| Diameter of spindle end chuck | Φ800 |

| Spindle center | Morse No. 6 |

| Tailstock center | Morse No. 6 |

| Tailstock center load | 15000Kg |

| Tailstock sleeve stroke | 150mm |

| Surface roughness of fine turning outer circle | ≤Ra0.8μm |

| Fine turning outer circle roundness | ≤0.01 mm |

| Minimum unit of longitudinal and lateral movement | 0.001 mm |

| X-axis ball screw nominal diameter | Φ63 |

| Z-axis ball screw nominal diameter | Φ80 |

| Positioning accuracy A (X axis) | 0.012mm |

| Positioning accuracy A (Z axis) | 0.045mm |

| Repeat positioning accuracy R (X axis) | 0.007mm |

| Repeat positioning accuracy R (Z axis) | 0.01mm |

| Reverse difference B (X axis) | 0.006mm |

| Reverse difference B (Z axis) | 0.012mm |

| Installation size of machining tool | 300*40*40mm |

| Machine size (length*width*height) | 6800*2800*1850mm |

| Net weight of machine tool | 20000Kg |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Nantong Yichuang Machinery Equipment Manufacturing Co., Ltd.

- *Message:

-

Submit

Main Product:

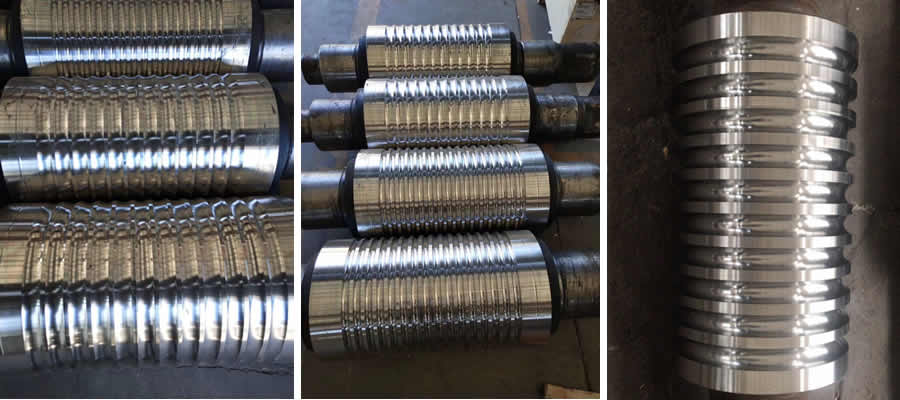

Roller Lathe,

Roll Milling Machine,

Roll Grinding Machine,

Thread Milling Machine ,

Machining center,

Roll Ring Grinder

You May Also Like