CT-c (99)

6 month agoFruit Slice Oven Description

CT-C series Fruit Slice Oven is the most often used convection chamber dryer. Inside the drying chamber of the Fruit Hot Air Dryer Oven, trays loaded with wet material are placed on top of each other in trolleys.

In drying process, fresh cold air is sucked into the drying chamber via the circulation fan and flows through the steam radiator or electrical heating tubes installed in the top to get required temperature. With the help of air distributor, hot air evenly flows through each layer of trays for heat transfer and carries way the evaporated moisture. Most of the damp air flows back to the circulation fan for circulation while part of the damp air is exhausted. The drying process is batch operation. After the drying is finished, open the chamber door and pull out the trolleys for unloading the dried product.

CT-C series Banana Slice Oven can be used for drying or heating almost all kinds of wet materials, such as liquid, slurry, paste, cake, powder, granule or sliced materials in almost all kinds of industries.

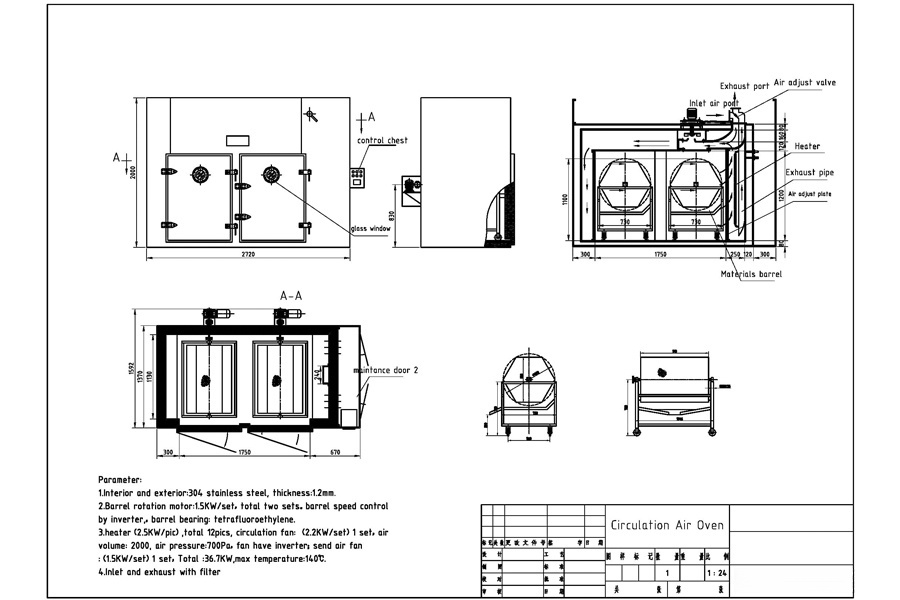

Main Parts of CT-C- Barrel Rotation Oven

Food hot air drying oven consists of several main parts like baking trays, fan, heater, tray cart and so on.

External cabinet

The External cabinet is made of stainless sheets. It covers the inner chamber.

Glass wool insulation

The space between the inner chamber and external cabinet is filled with Glass wool. It provides insulation to the hot air oven.

Inner chamber

The inner chamber of the hot air oven is made of Stainless steel.

Tubular air heaters

Heater help to generate heat within the inner chamber of the hot air oven. electrical heaters are located on up sides of the fruit hot air drying oven, and steam heater are located on the side of inner of the oven.

Motor-driven blower

It helps in uniformly circulating the air within the chamber. The fan is the auxiliary part of the fruit hot air drying oven with the power of 0.75kw / set. The materials for manufacturing fan are aluminum alloy or stainless steel.

Temperature sensor

It measures the temperature within the fruit hot air oven and displays it on the controller screen.

Tray cart

the cart load the tray and move inside the of food hot air dryer oven, The baking vehicles and its wheels are made of stainless steel. Their customization is also available.

Tray

Once Shaping Pressed Baking Trays are specially designed auxiliary products for hot air circulation drying oven. Generally, the baking tray is made with the standard size of 640*460*45mm and it also can be customized according to customers' demands.

Temperature controller: It maintains the accurate temperature during the entire cycle. It also controls the temperature and also displays the temperature values.

Hot air Oven specifications

|

Model |

Loading (Kg) |

Fan power (KW) |

Heating method |

Quantity of Tray cart |

Quantity of Tray |

Machine size |

Weight (Kg) |

|

CT-C-O |

60 |

0.75 |

Electrical /steam |

1 |

24 |

1.4×1.2×2.2 |

560 |

|

CT-C-I |

120 |

0.75 |

Electrical /steam |

2 |

48 |

2.3×1.2×2.2 |

1300 |

|

CT-C-II |

240 |

0.75x2 |

Electrical /steam |

4 |

96 |

2.3×2.2×2.2 |

1830 |

|

CT-C-III |

360 |

0.75x3 |

Electrical /steam |

6 |

144 |

3.4×2.2×2.2 |

2200 |

|

CT-C-IV |

480 |

0.75x4 |

Electrical /steam |

8 |

192 |

4.46×2.2×2.2 |

2800 |

|

1.Erbang Drying reserves the right to the design without notice 2.All specifications are as accurate as is reasonably possible, but they are not binding. |

|||||||

Hot Air Drying Oven Advantages

Erbang Drying CT series hot air fruit dryer had the following advantages over conventional solutions.

1. Robust drying chamber: The drying chamber is made by SUS304 or SUS316L steel plate, fully welded and mirror polished. The design is robust, simple and compact which requires minimum maintenance.

2. Uniform drying: Due to the specially designed air distributor, the hot air flow in each layer of trays is very uniform. The temperature difference inside the drying chamber is less than ±2 -3℃.

3. Energy saving: Most of the hot air circulates inside the well insulated drying chamber and only part of it is exhausted via the exhaust valve. The amount of exhaust air is adjustable according to different drying conditions.

4. Flexibility in heat source: The heat source can be steam, hot water, electricity to match with different working conditions.

5. Flexibility in drying: Standard sized (640x460x45mm) but different types of trays are available for different kinds of wet materials. The tray have standard tray, net tray and drill hole tray.

6. Convenient operation: Control cabinet is installed on drying chamber which can accurately control and set drying temperature and hot air flow rate.

7. GMP design: The drying chamber is fully welded, mirror polished without dead corners for cleaning to meet GMP standard.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Changzhou ErBang Drying Equipment Co., Ltd.

- *Message:

-

Submit

Main Product:

Ternary material reactor,

Drying Machine,

Granulating Machine ,

Grinding Machine,

Mixing Machine,

Coating Machine

You May Also Like