ZS (18)

5 month agoRound Screen Machine

Product Characteristics:

1. The Round Separator Machine often connect with drying machine, such as vibration fluid bed dryer, fluid bed dryer and so on.

2. The Vibratory Screen Device also connect with grinding machine such 30B grinding machine to make the big size materials into small pieces.

Product Features:

1. High efficiency, refined design, duration, any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenience washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

4. Discharge the impurity and coarse materials automobile and operates continuously.

5. Unique screen flame design, long duration of screen, only 3-5 to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 lagers are suggested.

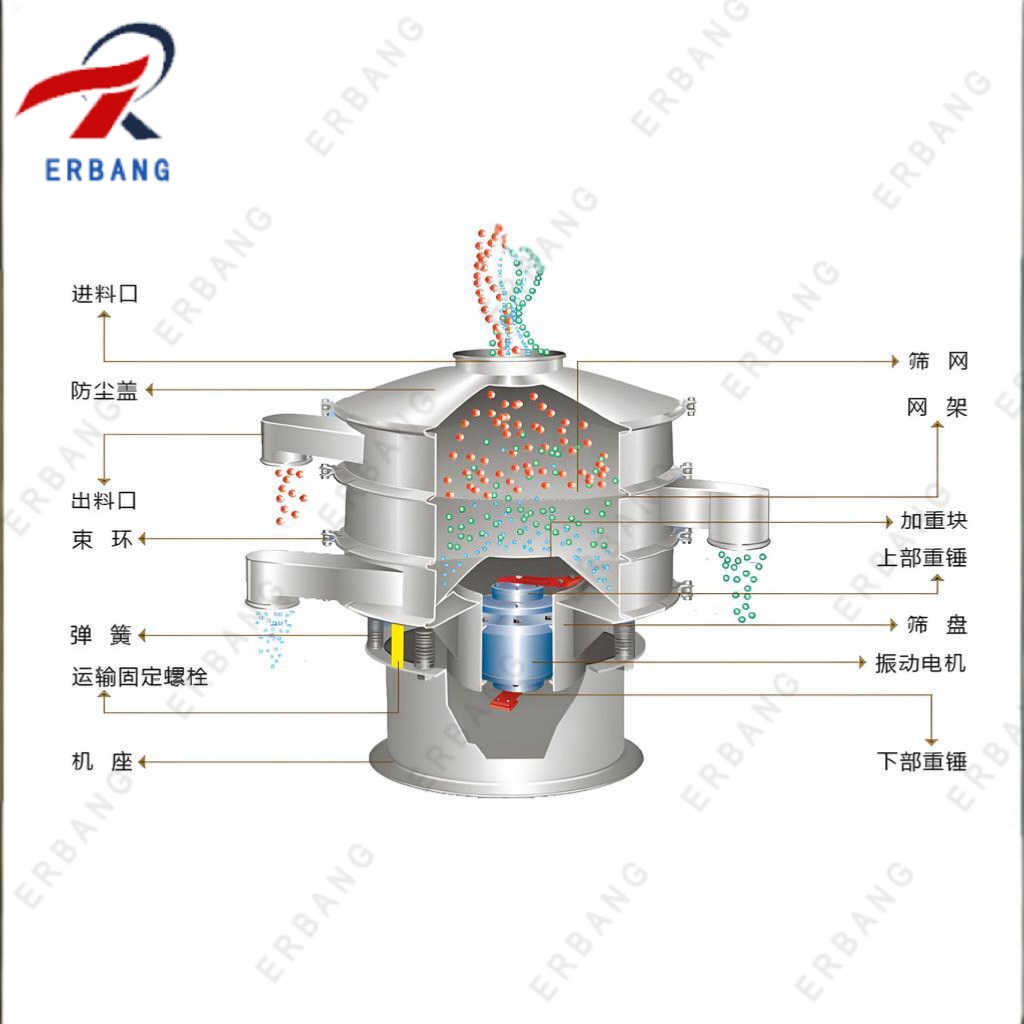

Pharma Materials Separator Principle of the structure

ZS series Vibrating Round Screen use upright motor as the source of vibration equipped eccentricity hammer on the both sides of motor, change circumrotate to level, upright and incline movement, then pass these three movement to the surface of the screen. Adjust the phasic angle on the both sides of the top and bottom to change the movement orbits of the surface screen.

| Model | capacity | Sieve hole | Power (vibration motor) | Power (common motor) | Vibration frequency | Weight |

| ZS-400 | 50-300kg/h | 3-200mesh | 0.18kw | 0.55kw | 1400r/min | 150kg |

| ZS-600 | 100-450kg/h | 3-200mesh | 0.25kw | 0.75kw | 1400r/min | 250kg |

| ZS-800 | 300-750kg/h | 3-200mesh | 0.55kw | 1.1kw | 1400r/min | 320kg |

| ZS-1000 | 400-1100kg/h | 3-200mesh | 1.1kw | 1.5kw | 1400r/min | 400kg |

| ZS-1200 | 600-1600kg/h | 3-200mesh | 1.1kw | 1.5kw | 1400r/min | 500kg |

| ZS-1500 | 800-1800kg/h | 3-200mesh | 1.5kw | 2.2kw | 1400r/min | 600kg |

| ZS-1800 | 1000-2000kg/h | 3-200mesh | 3.0kw | 3.0kw | 1400r/min | 800kg |

| ZS-2000 | 1300-2500kg/h | 3-200mesh | 3.0kw | 3.0kw | 1400r/min | 1000kg |

About Us:

Erbang Drying is a professional manufacturer of industrial drying machine, mixing machine and granulating machine. Our flagship products include the hot air dryer, vibration fluid bed dryer, belt dryer, vacuum dryer, one dimensional mixer, two dimensional mixer, three dimensional mixer, and high speed granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying ,mixing and granulating solutions. Erbang Drying constant faith is providing perfect products to customer, excellenting service to customer !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We Invite customers to visit our company and communicate on technical requirements face to face.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Changzhou ErBang Drying Equipment Co., Ltd.

- *Message:

-

Submit

Main Product:

Ternary material reactor,

Drying Machine,

Granulating Machine ,

Grinding Machine,

Mixing Machine,

Coating Machine

You May Also Like