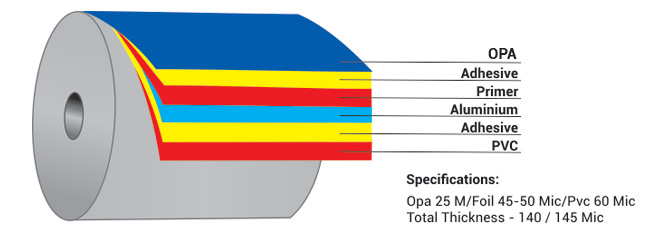

PVC Alu PE

6 month agoThe Application of Transparent PVC Film in PVC - Alu - Alu Composite Cold Aluminum Film

Introduction

In the packaging industry, the development of advanced composite materials has been crucial in meeting the diverse needs of product protection, preservation, and presentation. The PVC - Alu - Alu composite cold aluminum film, with the incorporation of transparent PVC film, has emerged as a significant innovation. This article will explore the various aspects of using transparent PVC film in the PVC - Alu - Alu composite cold aluminum film, including its material properties, manufacturing process, applications, advantages, and challenges.

Material Properties of Transparent PVC Film

Chemical Composition and Structure

Transparent PVC film is composed of polyvinyl chloride polymers. The molecular structure of PVC consists of long chains of carbon, hydrogen, and chlorine atoms. The chlorine atoms in the structure contribute to its unique properties, such as chemical resistance and flame retardancy. The polymerization process of PVC can be adjusted to control the molecular weight and degree of polymerization, which in turn affects the physical and chemical properties of the film. The transparency of the PVC film is achieved through careful manufacturing processes that minimize the presence of impurities and ensure uniform molecular alignment.

Transparency

The transparency of PVC film is one of its most notable features. It allows for clear visibility of the contents packaged within the PVC - Alu - Alu composite cold aluminum film. This is particularly important in applications where the product needs to be showcased, such as in the packaging of cosmetics, pharmaceuticals, and luxury goods. The high - level transparency is maintained over time and under different environmental conditions, providing a reliable window for consumers to view the product.

Mechanical Properties

PVC film exhibits good mechanical strength. It has a certain tensile strength that enables it to withstand stretching and pulling forces during the manufacturing process and in use. The film also has flexibility, which allows it to conform to the shape of the aluminum layers and other components in the composite. This flexibility is beneficial in preventing cracks and breaks during handling and transportation. Additionally, the film has a degree of puncture resistance, protecting the integrity of the composite structure from accidental damage.

Barrier Properties

In terms of barrier properties, transparent PVC film offers protection against moisture, gases, and other environmental factors. It can act as a barrier to prevent the ingress of moisture, which is crucial for products that are sensitive to humidity, such as food items and electronic components. The film also provides some resistance to gases like oxygen and carbon dioxide, helping to maintain the freshness and quality of the packaged product. However, its barrier properties may be enhanced when combined with the aluminum layers in the PVC - Alu - Alu composite.

Chemical Resistance

PVC film is known for its chemical resistance. It can withstand contact with a variety of substances, including oils, acids, and alkalis. This property makes it suitable for packaging products that may contain or come into contact with such chemicals. For example, in the pharmaceutical industry, where drugs may have different chemical compositions, the PVC film can provide a protective layer without reacting with the active ingredients.

Manufacturing Process of PVC - Alu - Alu Composite Cold Aluminum Film with Transparent PVC Film

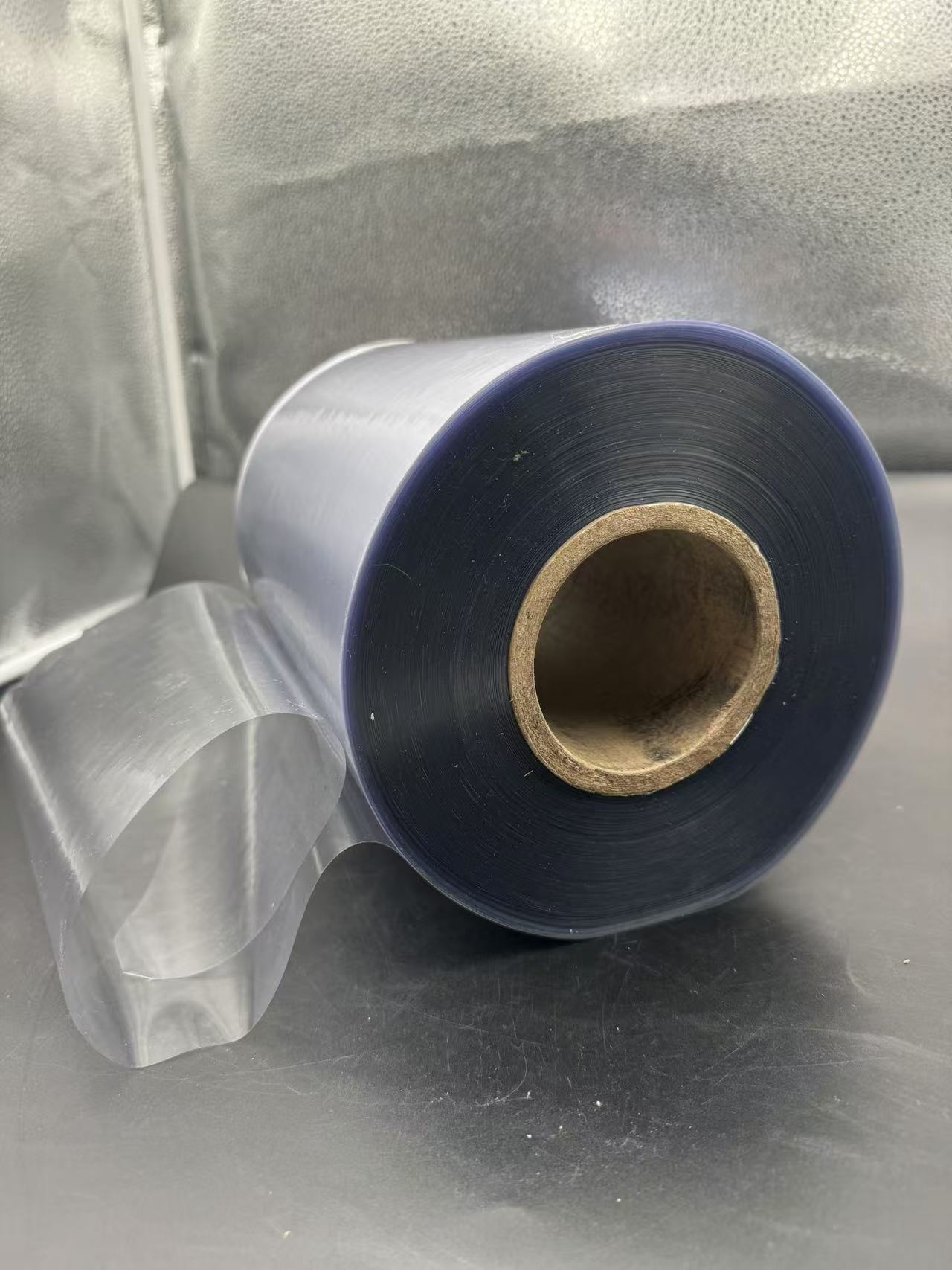

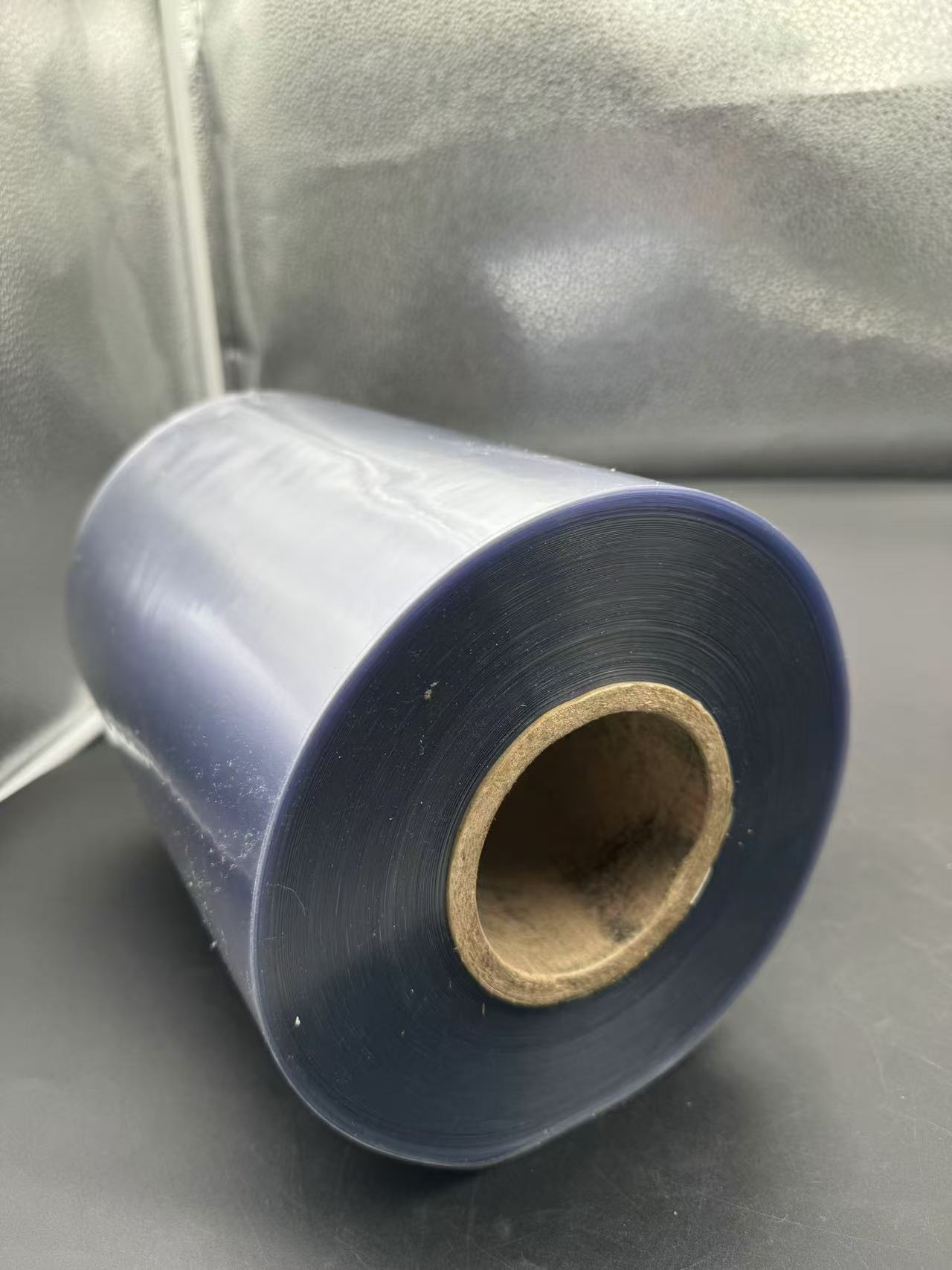

Preparation of Transparent PVC Film

The production of transparent PVC film starts with the selection of high - quality PVC resin. The resin is mixed with various additives, such as plasticizers to improve flexibility, stabilizers to enhance thermal stability, and lubricants to facilitate the extrusion process. The mixture is then fed into an extruder, where it is heated and melted. The molten PVC is forced through a die to form a continuous sheet of film. The thickness of the film is precisely controlled, and it is cooled and wound onto rolls for further processing.

Aluminum Layer Preparation

The aluminum layers in the PVC - Alu - Alu composite are typically produced by aluminum foil manufacturing processes. High - purity aluminum is melted and then rolled into thin foils of specific thicknesses. These aluminum foils are further processed to ensure their surface quality and flatness. They are cleaned and treated to enhance their adhesion properties with the PVC film and other layers in the composite.

Lamination Process

The lamination of the transparent PVC film with the aluminum layers is a crucial step. The PVC film is first coated with an adhesive layer. The adhesive is carefully chosen to ensure good bonding between the PVC and the aluminum. The aluminum foils are then placed on either side of the PVC film, and pressure and heat are applied to complete the lamination. The lamination process is carried out under controlled conditions to ensure uniform adhesion and to avoid air bubbles or wrinkles in the composite. In some cases, additional layers or coatings may be added to further enhance the properties of the composite, such as a protective varnish layer on the outer surface of the PVC film.

Quality Control and Finishing

After the lamination, the PVC - Alu - Alu composite cold aluminum film undergoes rigorous quality control. The thickness of the composite, the adhesion between the layers, and the transparency of the PVC film are all tested. Any defects or non - conformities are identified and corrected. The composite film is then cut into the desired sizes and shapes, and it may be further processed, such as by printing or adding perforations for easy opening.

Applications of PVC - Alu - Alu Composite Cold Aluminum Film with Transparent PVC Film

Pharmaceutical Packaging

The use of transparent PVC film in PVC - Alu - Alu composite cold aluminum film has opened up new possibilities in packaging. It offers a combination of product protection, visual appeal, durability, and customizability that is highly valuable in industries such as pharmaceuticals, food, and cosmetics. Despite the challenges related to environmental concerns, adhesion, cost, and regulatory compliance, there are solutions and strategies available to address them. As technology and manufacturing processes continue to evolve, the PVC - Alu - Alu composite cold aluminum film is likely to remain an important packaging solution, providing high - quality and effective packaging for a wide range of products. Manufacturers, packaging designers, and industries will continue to explore and optimize the use of this composite film to meet the ever - changing demands of the market and consumers.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film ,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products

You May Also Like