hard fast door

2 year ago

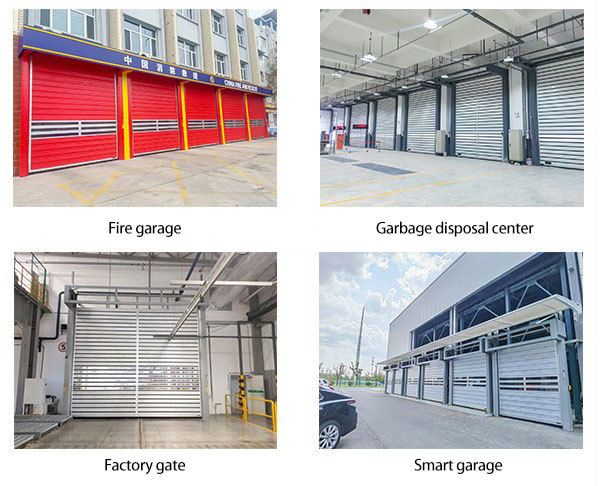

Redefining industrial access, the High-Frequency Industrial Rapid Door Aluminum Spiral is an innovative system that merges the most advanced features of three specialized doors: the High-Speed Spiral Door, the High-speed Insulated Aluminum Door, and the Rapid Aluminum Rolling Door. This integration results in a door that excels in speed, efficiency, and durability, meeting the demands of fast-paced industrial and commercial environments.

Engineered to withstand high winds and frequent use, the High Speed Spiral Door component ensures a secure and stable barrier. Its aluminum spiral design not only resists wind pressure but also contributes to the door's swift and reliable operation, even in challenging weather conditions.

The High-speed Insulated Aluminum Door enhances energy efficiency with its ability to minimize heat transfer. The insulated panels are designed to maintain a steady temperature, which is critical in controlled environments, and also feature sound-damping properties to create a quieter workspace.

For facilities where swift transitions are crucial, the Rapid Aluminum Rolling Door provides immediate access. Its rapid opening and closing cycle optimize the flow of people and goods, thereby maximizing productivity. The door's aluminum construction, reinforced for added strength, ensures it can withstand heavy traffic and continue to operate smoothly.

Designed for ease of installation and low maintenance, the High-Frequency Industrial Rapid Door Aluminum Spiral offers a cost-effective choice with a long service life. Its resistance to corrosion assures durability in harsh industrial conditions.

Safety is a priority, with features such as an automatic closing mechanism that prevents accidental opening and an aluminum structure that provides robust support. Insulated panels further enhance security by containing noise and heat.

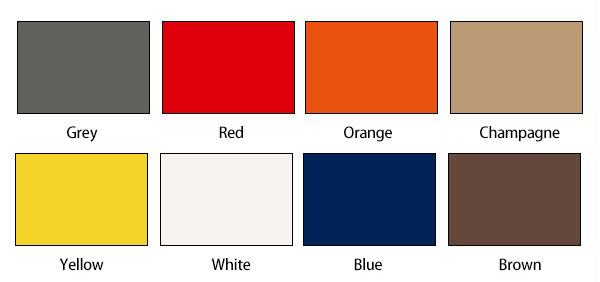

Customizable to fit a variety of openings and configurations, the High-Frequency Industrial Rapid Door Aluminum Spiral is a versatile solution for diverse industrial settings. It can be precisely adapted to meet the unique requirements of small factories or large warehouses.

In summary, this door system represents a significant advancement in industrial access control, offering a blend of high-performance features from its three constituent doors. It is an ideal selection for industrial settings aiming to improve operational efficiency, safety, and comfort, delivering a dependable and economical access solution.

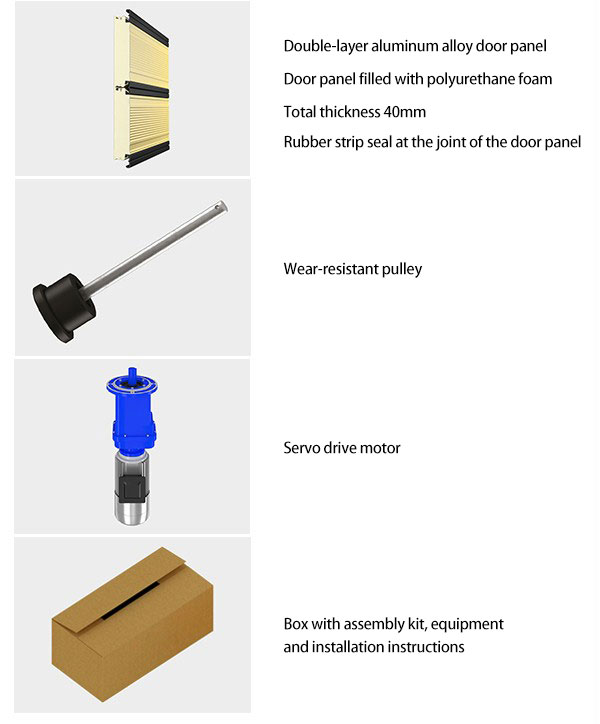

thickness of the door panel is 40mm with a volume density of 250kg per cubic meter, and the heat insulation structure is designed.

2. The four-fold sealing structure technology ensures the airtightness and isolation effect inside and outside the door, and the

airtightness is 8.68m³/(㎡xh).

3. The integrated transmission system of the pulley and the track balance mechanism enables the door to run lightly, smoothly and

quickly.

4. Using a dedicated servo system, the core is a DSP processing chip, the system can precisely control the operation of the door

body, and the standard infrared safety anti-pinch device.

|

Features

|

Suitable for outdoor doors that are frequently opened and closed, with functions such as fast speed, strong wind resistance, and good thermal insulation performance

|

|

|

|

|||

|

Door curtain material

|

0.7mm aluminum alloy door panel, filled with polyurethane foam for heat preservation inside, and the thickness of the door panel is 42mm

|

|

|

|

|||

|

Door frame material

|

2.5mm galvanized steel paint frame

|

|

|

|

|||

|

Control system

|

Standard microcomputer control system\Open, Close, Stop buttons\Switch man-machine English interface\LCD display, fault code prompt

|

|

|

|

|||

|

Security system

|

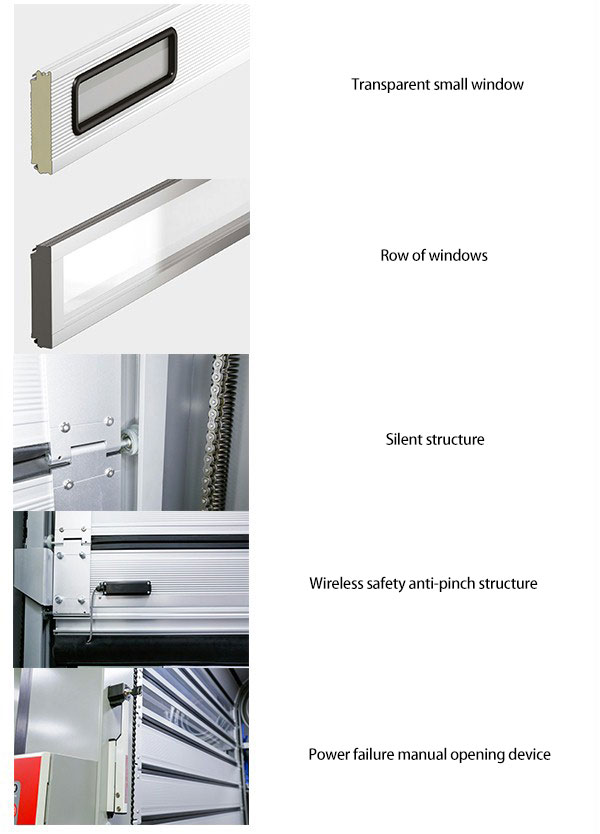

Photoelectric protection (standard configuration)\Wireless safety bottom edge protection (standard)\Grating protection (optional)

|

|

|

|

|||

|

Drive system

|

Servo motor, reducer

|

|

|

|

|||

|

Motor position

|

Default right

|

|

|

|

|||

|

Wind resistance level

|

11 winds (national standard)

|

|

|

|

|||

|

Maximum speed

|

2.0m/s

|

|

|

|

|||

|

Emergency door opening

|

Support

|

|

|

|

|||

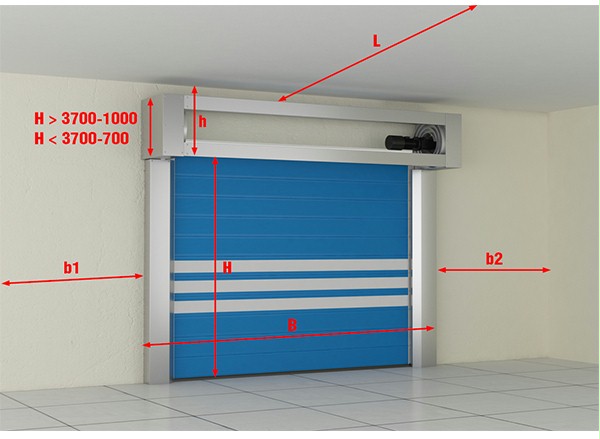

B--the width of the door opening (the distance from the left edge of the door opening to the right edge)

h--Above the doorway (the distance from the top of the doorway to the ceiling) is generally reserved 900mm

b1/ b2 is the left/right lateral distance of at least 350 mm (distance from the corresponding edge of the door opening to the obstacle)

L is the depth of the room.

When measuring h, b1, b2 and L, take the smallest value as the final size.

2. Make sure that people and objects are not within the lowering range of the door body during the operation.

3. It is strictly forbidden to move below when the door is closed, because it will cause damage.

4. When the spiral door is opened and closed, do not impact the door body or interfere with its normal operation.

6. Make sure that there are no foreign objects and debris in the track during operation, which may cause the door to tilt and get stuck.

Notice! If abnormalities are detected, stop operation immediately.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- NingBo AnSheng Door Industry Technology Co.,Ltd.

- *Message:

-

Submit

Main Product:

pvc fast door,

pvc zipper fast door features,

pvc rapid stacking door,

industrial sliding door,

steel door ,

unloading platform

You May Also Like