CNC processing tungsten steel mold side hole is a precise processing process, which is mainly used to make molds with high hardness and wear resistance. Tungsten steel (hard alloy) is widely used in mold manufacturing due to its high hardness and good abrasion resistance. Here are some basic information about how to perform the side hole of CNC processing tungsten steel mold:

1. ** Material preparation **: First of all, you need to prepare the required tungsten steel materials and ensure that the size meets the design requirements.

2. ** CAD/CAM software design **: Use computer -aided design (CAD) software to design the three -dimensional model of the mold, and then use a computer -assisted manufacturing (CAM) software to generate processing paths and programs.

3. ** Machine tool setting **: Select the appropriate CNC machine tool according to the processing requirements and install appropriate tools. For high -hardness materials such as tungsten steel, high -speed steel or harder ceramic tools are usually required.

4. ** cooling and lubrication **: Since the tungsten steel material will generate a lot of heat during the processing process, the cooling solution is needed to reduce the temperature, and at the same time, it also helps improve the life of the tool and the processing accuracy.

5. ** Machining process **: According to the pre -set program, CNC machine tools will automatically complete drilling, milling and other operations. For side holes, multiple positioning and adjustment may be required to ensure accuracy.

6. ** Quality inspection **: After the processing is completed, carefully check the mold, including size, shape, and surface smoothness to ensure that it meets the design requirements.

7. Post -processing after **: If necessary, it can be further polished or other surface treatment of the mold to improve its performance.

Dongguan Fengguan Precision Technology Co., Ltd. is located in Changan Town, Dongguan City, which is the main center of Zhuzhou cemented carbide in Dongguan. The main tungsten carbide materials, tungsten steel mold deep processing and all kinds of tungsten steel precision accessories. The cemented carbide series mainly produced and sold are: cemented carbide tungsten steel plate, cemented carbide tungsten steel round rod, cemented carbide tungsten steel strip, cemented carbide tungsten steel round die, diamond tungsten steel, various kinds of cemented carbide tungsten steel non-standard blank, non-magnetic tungsten steel, hard alloy drawing die, tungsten steel pipe shrinking die, tungsten steel pipe drawing die, tungsten steel forming die, tungsten steel punching die, powder metallurgy die, tungsten steel sealing die, Tungsten steel insert sleeve, Tungsten steel extrusion die, Tungsten steel roll, Tungsten steel guide rail, Tungsten steel sealing ring, Tungsten steel punching and shearing die, Tungsten carbide wear-resistant parts, Tungsten wear-resistant steel, Tungsten corrosion-resistant steel, Tungsten steel conductive block, Tungsten steel punch, Tungsten steel bushing, Tungsten steel parts, cemented carbide ball, Tungsten steel milling cutter, diamond blade, Tungsten steel processing, etc. The main products are: Tungsten Steel Stretching Mold,CNC Processing Tungsten Steel Products,Tungsten Steel Die Material,Tungsten Carbide Custom Machining,Tungsten Steel Precision Machined Parts,New Energy Materials Ceramic Aluminium Oxide Zirconia。

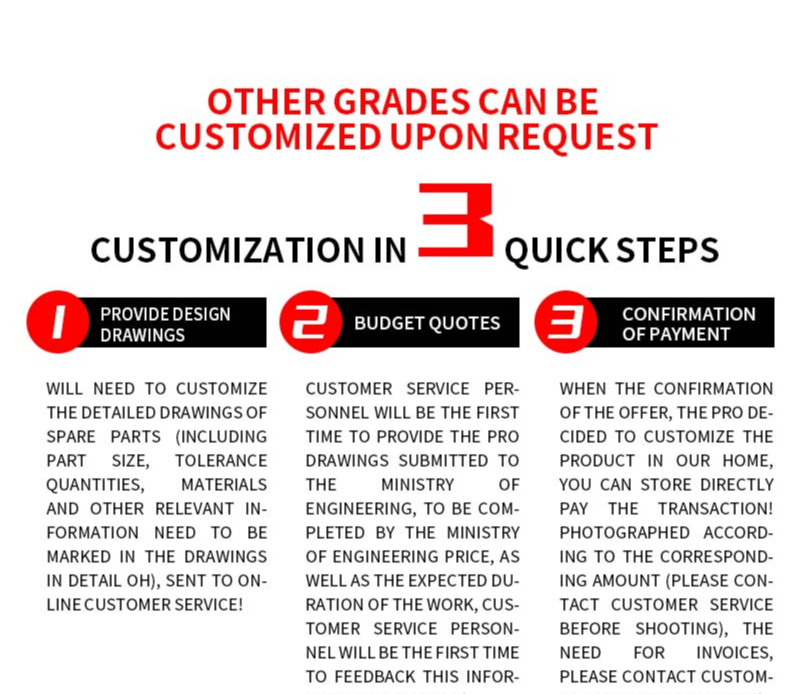

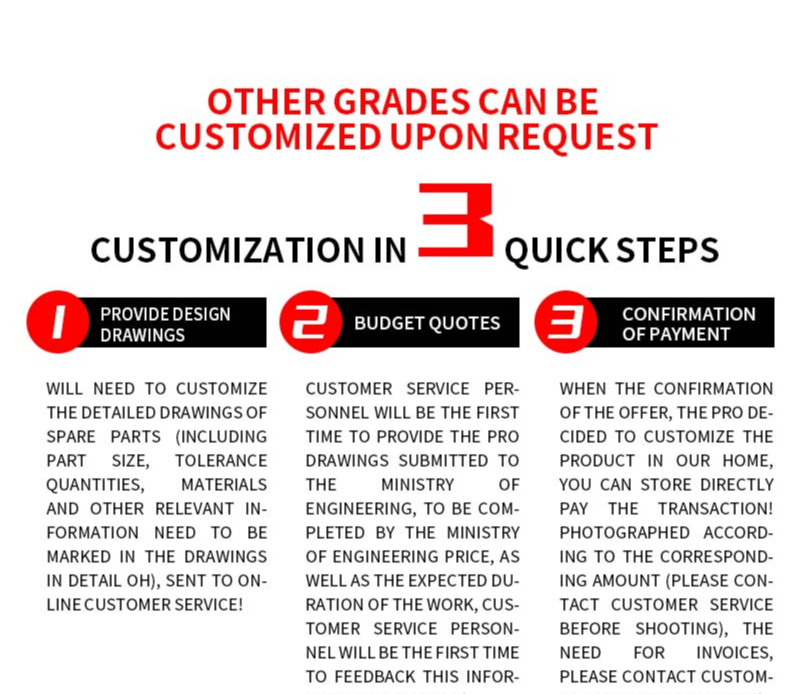

Please provide the product CAD drawings you need, we will serve you wholeheartedly to solve your needs for mold accessories and other products!