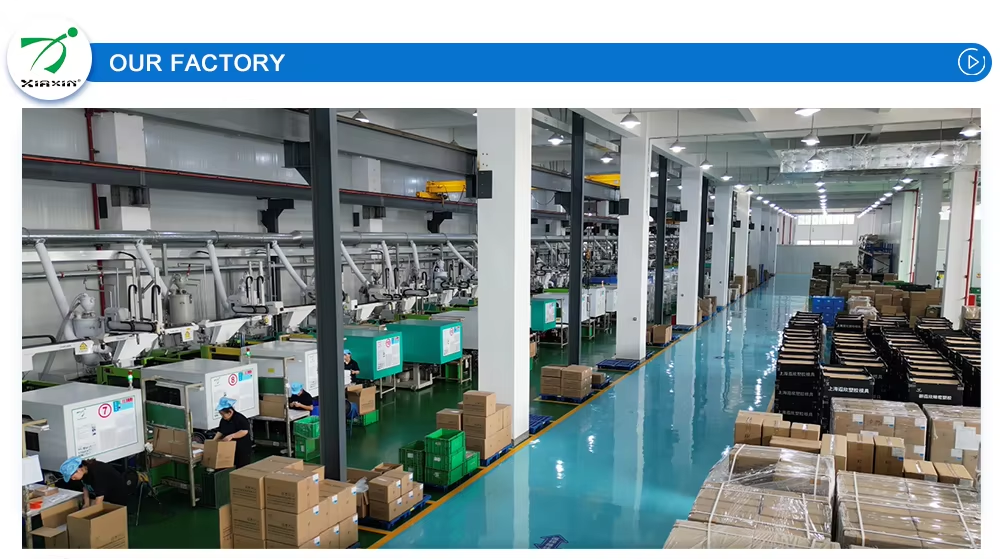

Injection molded parts silk screen production line

4 month ago

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

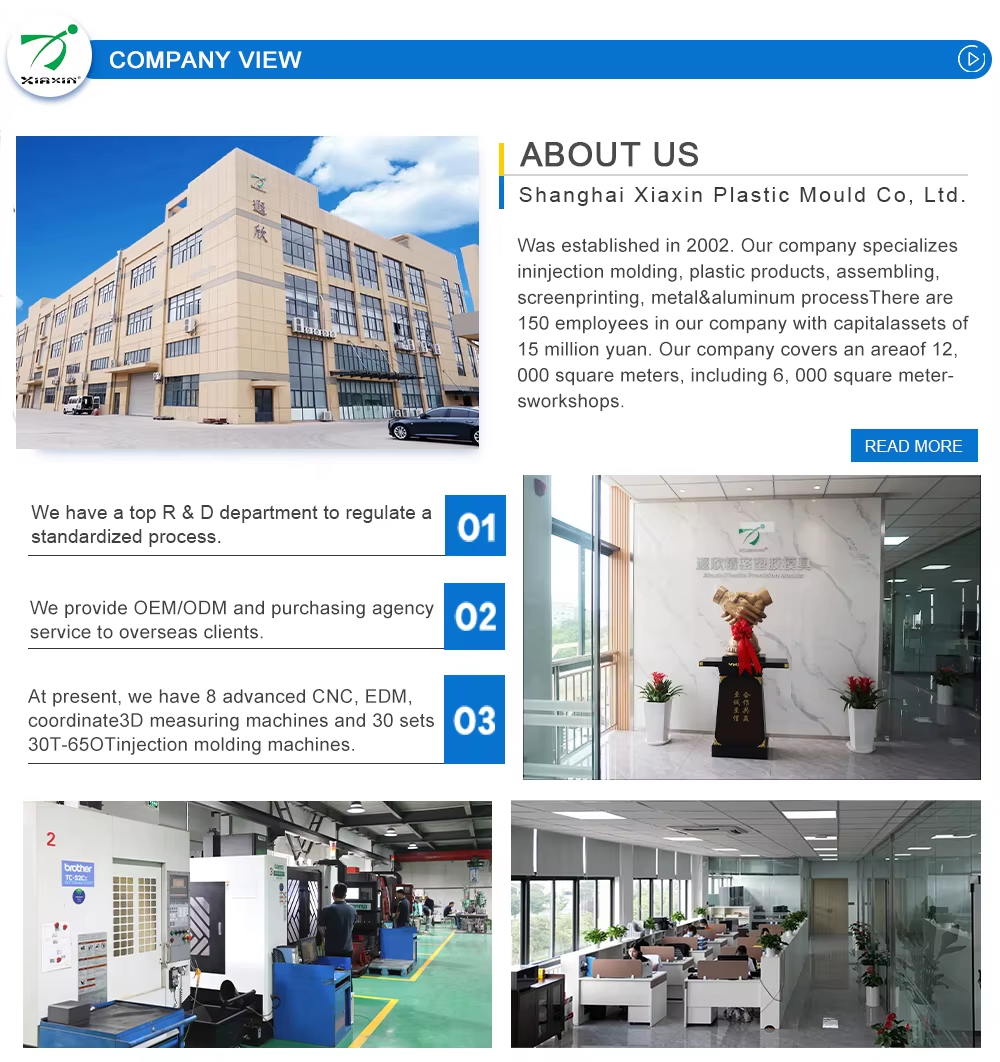

- Shanghai Xiaxin Plastic Mold Co., Ltd

- *Message:

-

Submit

Main Product:

Mold processing ,

Injection molding,

Custom machining,

Plastic and rubber products,

Printing and packaging,

Product assembly

You May Also Like