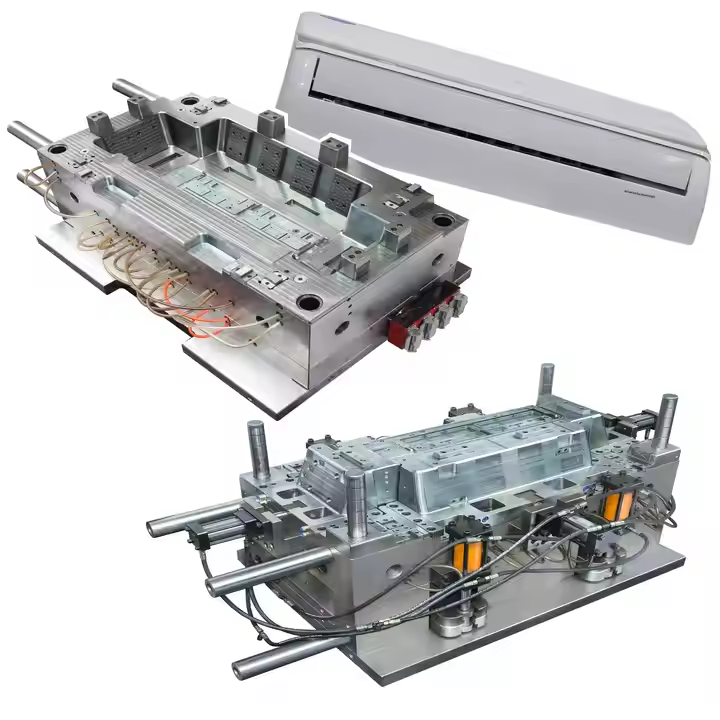

Injection molded plastic shell, air conditioner shell 2-8

3 month agoWith advanced consciousness, brand-new concepts and innovative spirits, we integrate advanced technologies at home and abroad to continuously research and develop new Plastic Crate Mould, Plastic Mould For Toilet Cover, Infant Seat Mould for the industry. With the efforts of all employees, our business capabilities have improved by leaps and bounds. The company regards integrity, responsibility and innovation as its continuous pursuit and goal, and is willing to join hands with our friends to create a better tomorrow. We cultivate a responsible, serious, learning organization and execution team. We pay great attention to responsibility, not only to the market, but also to our employees and society.

Air conditioners often use a fan to distribute the conditioned air to an enclosed space such as a building or a car to improve thermal comfort and indoor air quality. Electric refrigerant-based AC units range from small units that can cool a small bedroom, which can be carried by a single adult, to massive units installed on the roof of office towers that can cool an entire building. The cooling is typically achieved through a refrigeration cycle, but sometimes evaporation or free cooling is used.

Mould Information

Mould Name: Plastic Air Conditioner Shell Injection Mould

Plastic material: ABS

Steel of Cavity & Core: S136

Steel of Mould base: S50C. LkM standard

Hardness of Cavity & Core: 48-52HRC

Hardness of Wear Parts: 55-60HRC

Core pulling system: Motor /oil cylinder/ stripping plate

Mould Accessories: DME/HASCO Standard

Cooling system: In core baffle cooling and in cavity plate chain drilling type cooling

Surface finish: Diamond polish

Molding life: 500, 000shots

Runner: Cold

Delivery time: 40work days

This outdoor air conditioner cover will protect your air conditioner outdoor unit from rain, snow, sunlight, dust, and debris

Plastic Air Conditioner Cover

ZIBO HUIWEN Plastics offers a full range of plastic molding capabilities to efficiently mass-produce parts specializing in injection molding and have served customers in variety of industries such as medical, automotive, packaging, construction, home appliances , and agriculture. The company has two factories which occupy a total area of more than 18,000 square meters, and a total of 102 sets of injection molding machines .We deal with design and manufacture of Home Appliance Plastic Accessories,Automotive Plastic Accessories,Furniture Plastic Fittings, Daily Plastic Parts , Other Plastic Parts ,Refrigerator Plastic Accessories,TV Plastic Accessories, Washing Machine Plastic Accessories, Air Conditioning Plastic Accessories.

and so on, specializing in using ABS/PC/PP/HDPE/PVC/PET Ect plastic raw material to adjust production process appropriately so that products can achieve the best performance.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- ZIBO HUIWEN NEW MATERIAL CO., LTD

- *Message:

-

Submit

Main Product:

Refrigerator Plastic parts,

TV Plastic parts,

Washing Machine Plastic parts,

Air Conditioning Plastic parts,

Daily Plastic Parts,

Industrial plastic parts

You May Also Like