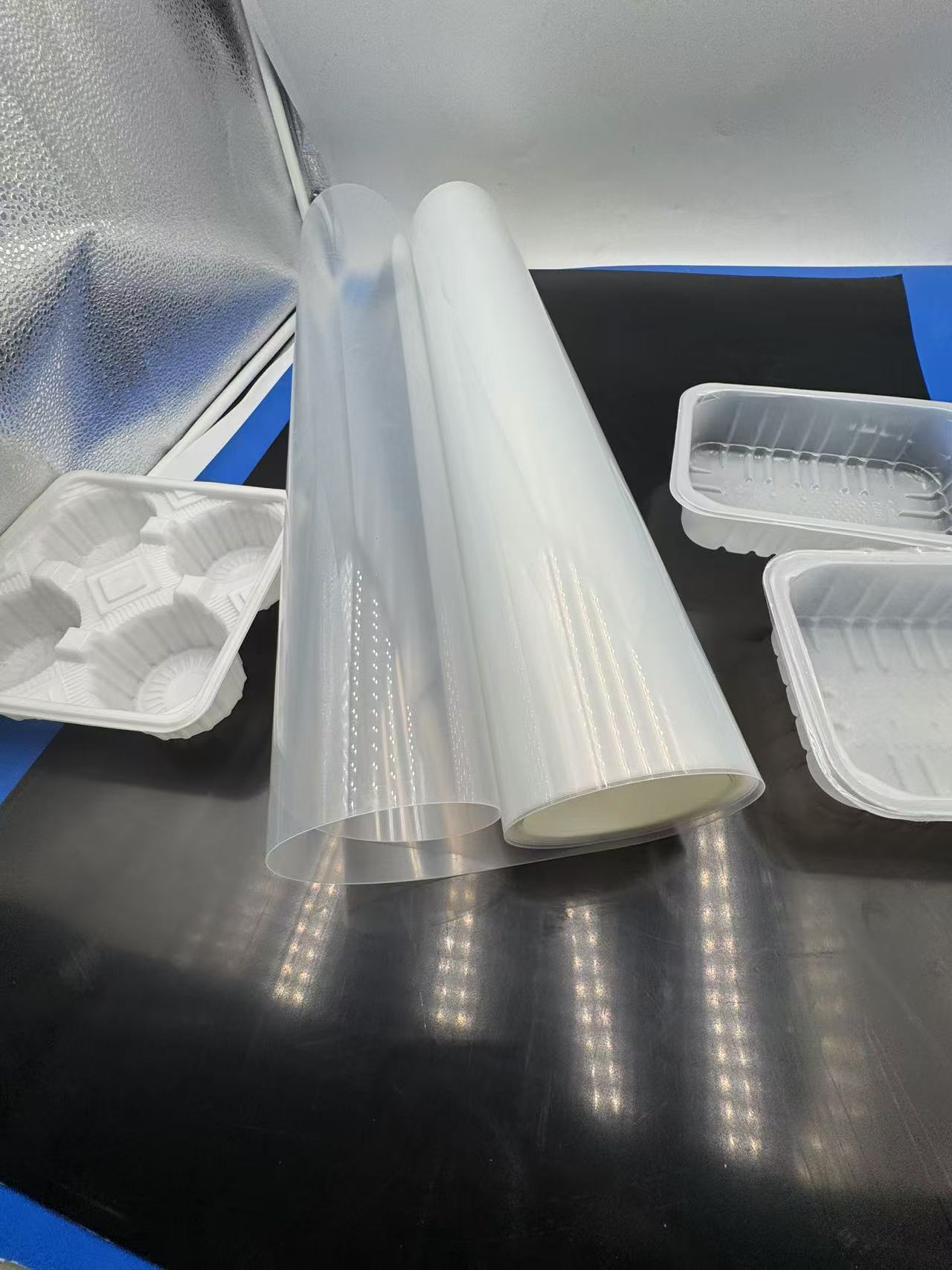

Applications of High-Transparency PP Film to Many Fields

3 month agoApplications of High-Transparency PP Film to Many Fields

I. Introduction

In this era of rapid development in the field of materials science, high-transparency PP film has prominently shown its advantages of unique properties and wide applicability in many aspects.

From the daily food packaging to the sophisticated insulation for batteries, the quiet changing of life and industrial production is done by high-transparency PP film. The following article will explain in detail the fantastic applications of high-transparency PP film in food blister packaging, fresh meat freezing boxes, microwave-heatable takeout packaging, and battery insulation.

II. Properties of High-Transparency PP Film

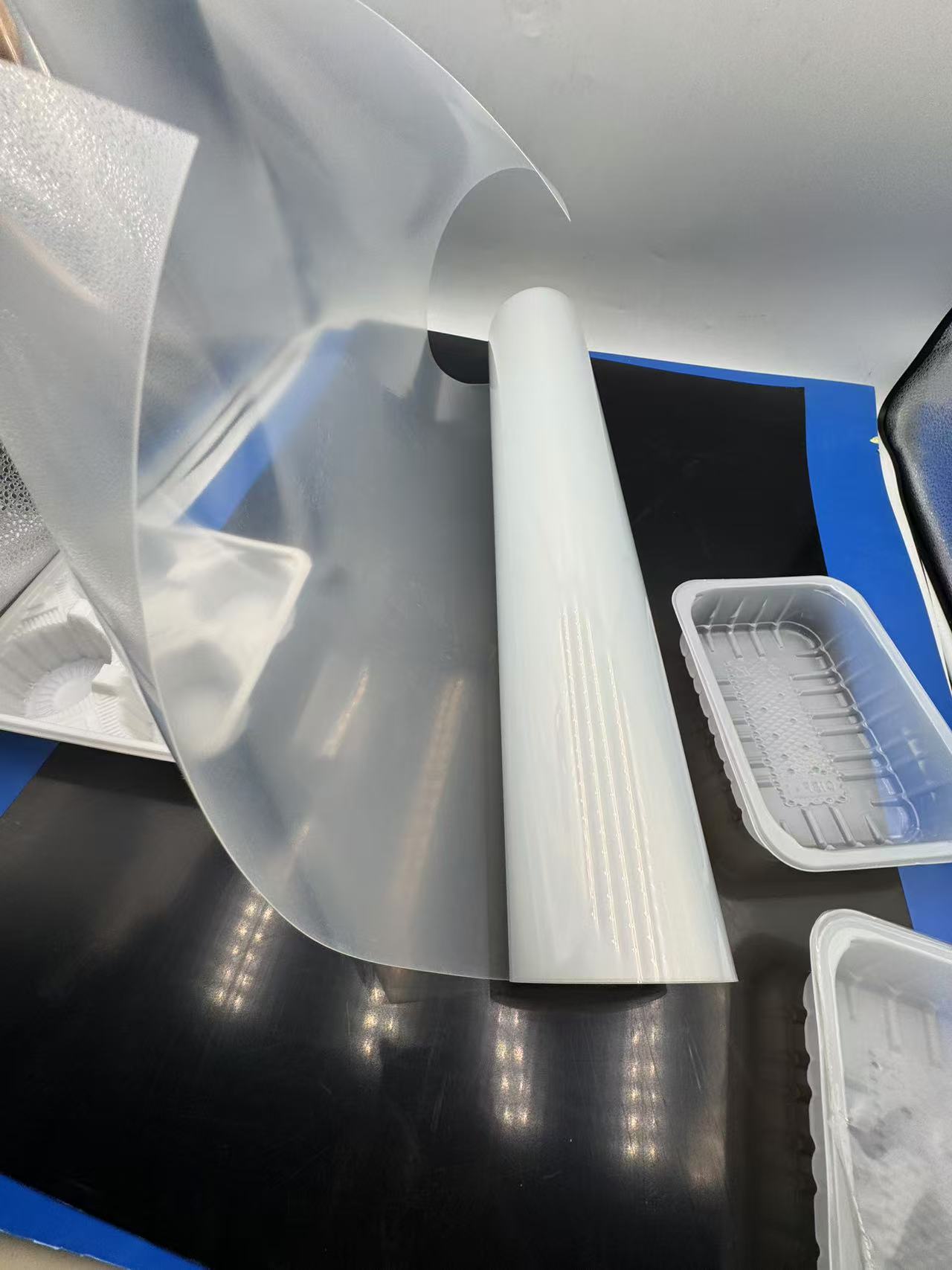

(I) Exceptional Transparency

High-transparency PP film has very high transparency, almost equal to that of glass. This property makes the products inside the packaging clearly visible. Whether it is colorful food or exquisitely designed goods, they can be perfectly presented through high-transparency PP film. In the food packaging field, consumers can directly observe the color, shape, and texture of the food, which greatly increases their desire to purchase. For example, the high-transparency PP film used in the blister packaging of fruits makes the fruits fresh and right in front of them. (II) Good Mechanical Properties PP film is of relatively high strength and toughness, not easy to rupture, and able to bear a certain degree of stretch, squeeze, and puncture. In blister packaging of food, though it suffers a lot from bumps and squeezes during transportation, the package can be made of high-transparency PP film to protect the internal food effectively. For fresh meat freezing boxes, in the freezing-thawing cycle, PP film maintains its structural integrity with no rupture that may cause blood leakage.

(III) Chemical Stability

PP film shows good chemical resistance against many chemical substances: It cannot have any chemical reactions with components in foods such as oils, acids, and alkalis, since it is resistant; hence, it assures that foods will retain their quality and be safe to eat. A very important characteristic, above all in packaging for food purposes, avoiding food contamination for the package per se:. In the field of battery insulation, high-transparency PP film can bear the erosion of chemical substances inside the battery and ensure that the battery works steadily. (IV) Temperature Resistance PP film has a relatively wide temperature-resistance range. It has good flexibility at low temperatures, which makes it suitable for freezing packaging such as fresh meat freezing boxes. It can also remain unmelted and undeformed in the relatively high temperatures required for microwave-heated takeout packaging. In general, PP film withstands temperature changes from -20 to around 120C°, which makes it able to perform exceedingly well under various application conditions.

(V) Hygiene and Safety

High-transparency PP film is up to the stringent food hygiene standards, nontoxic, and odorless. Thus, all kinds of food packaging will not be harmful to human health. For instances that require direct contact with food, like blister packaging, taking out packaging, or fresh meat freezing boxes, the hygiene and safety requirements are very high, and the PP film will precisely meet this key requirement.

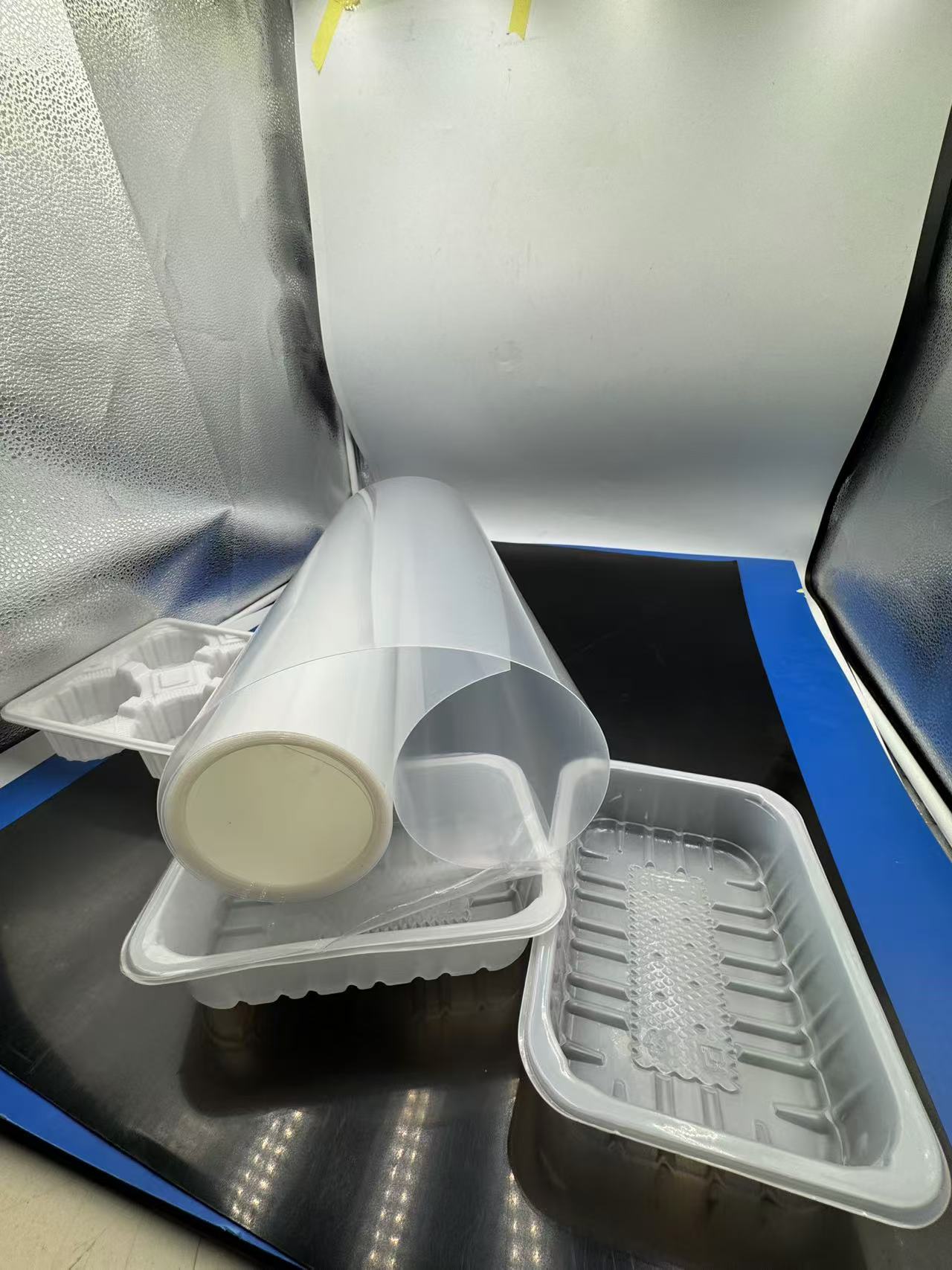

III. Applications of High - Transparency PP Film in Food Blister Packaging

(I) Display Effect and Marketing Advantage

Food blister packaging needs to highlight the appearance of the product to attract consumers' attention. The high transparency of high-transparency PP film makes the food stand out on the shelves. For example, in the blister packaging of baked goods, golden and crispy bread and delicate pastries are shown through the highly transparent PP film. Their attractive colors and shapes seem to invite consumers. This intuitive display effect can significantly increase product sales and bring greater market competitiveness to food enterprises.

(III) Environmental Protection and Sustainability

(II) Blocking Blood-water and Hygiene

Fresh meat will have blood-water seepage during the freezing and thawing process. The high-transparency PP film has an excellent barrier function, effectively blocking blood-water from seeping out and ensuring cleanliness and hygiene in packaging. This not only prevents further contamination by/ of other foodstuffs/ environment but it also blocks loss of blood-water in preventing the nutritional component - taste deterioration in fresh meat. Simultaneously, this provides hygiene and safety to PP films so that no potential harm can arise to human health due to its direct contact with fresh meat.

III. Clarity

When consumers are buying fresh meat, they want to clearly see the quality of the meat. The highly transparent high-transparency PP film will enable consumers to directly observe the color and texture, freshness of the fresh meat, and therefore increase the consumer's trust in the product. High-transparency PP film fresh meat freezing boxes in supermarket freezers will make the fresh meat catch the eyes of consumers, attracting the attention of consumers and hence stimulating sales.

(II) Convenience and Practicality

Takeaway packages can be heated in a microwave oven, and high-transparency PP film makes the package light and easy to carry. In this fast-paced modern life, people hope that the take-out packaging is convenient to heat up, carry, and use directly. PP film packaged meets these requirements. Whether in the office, at home, or outdoors, consumers can easily heat the takeout food in a microwave oven and enjoy delicious food. Besides, the transparency of PP film can make consumers observe the state of the food without opening the package, which is more convenient.

(II) Chemical Stability and Battery Life

The inner chemical environment of the battery is rather complex; insulating materials should be resistant to erosion by chemical substances. High-transparency PP film has good chemical stability that is able to maintain stability in the chemical environment inside the battery without any chemical reaction with components such as electrolytes in the battery. This not only ensures the normal service life of the battery but also extends the service life of the battery. As an example, applying high-transparency PP film in the battery packs of electric vehicles can enhance the reliability and durability of the battery and support large-scale application. (III) Process Adaptability

Due to the continuous development of science and technology, changes in market demand, high-transparency PP film will be able to enter a wider range of applications, constantly being optimized and innovated, adding more convenience to people's lives and industrial production. Transparency-high PP film will always play a pivotal role in developing and furthering the course of various industries, be it at the level of daily life or high-technology industry.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film ,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products

You May Also Like