Doffer and Cylinder Roller Video

5 month ago

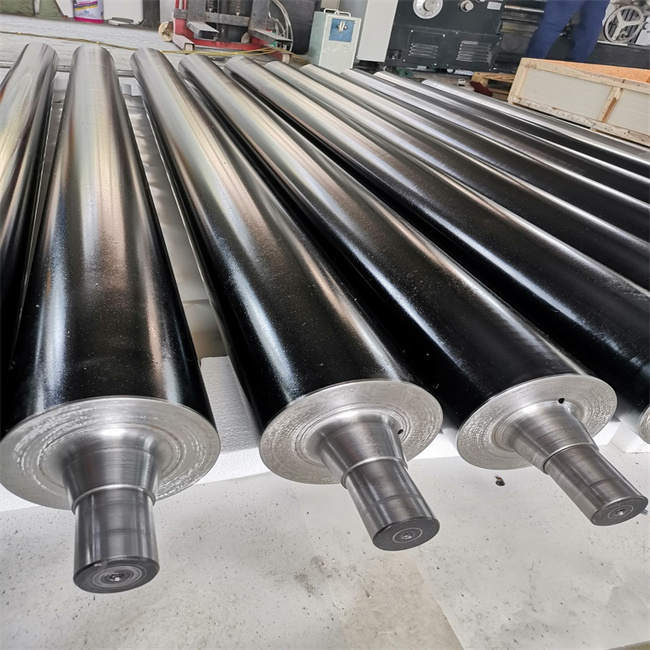

Cylinder Roller for Carding Machine

Introduction of Cylinder Roller:

Cylinder is generally composed of multiple rotating rollers, and there are many comb teeth on the inner surface of each roller. These comb teeth pull the fibers out and give them a certain direction and position. In addition, cylinder can also control the length and fineness of the fiber to ensure that the fiber will not break during the stretching process. Therefore, cylinder plays a very important role in the working process of roller carding machine.

Function of Cylinder Roller:

The cylinder action fully and meticulously combs the fibers stripped from the licker-in, especially the fiber bundles that cannot be combed by the licker-in into single fibers. During the carding process, short lint and impurities are removed, while some fibers are straightened and mixed uniformly, and then transferred to the doffer.

Technical Data of Cylinder Roller:

Regulation :φ1230 /1500 or as customized

Material: Steel

Runout:10um-20um

Advantage of Carbon fiber guide roller:

Carbon fiber has small density and light weight. Its specific gravity is 60% of aluminum alloy, but its tensile strength can reach more than 3000MPa, which is more than 6 times that of steel. Compared with aluminum alloy rollers, lighter carbon fiber rollers can speed up the start and stop of the machine, reduce inertia, and increase the speed of the rollers, thereby effectively reducing energy consumption and improving production efficiency

Technical Data of Carbon fiber guide roller:

Roller body material: high performance carbon fiber composite material

Weight: 18kg, composite material density 1600kg/m³

Maximum diameter: can be designed and manufactured <1000mm

Maximum length: can be designed and manufactured <6000mm

High stiffness: 100N/m, deflection deformation 0.03mm/m, or the stiffness can be designed, the machine tool runs smoothly

Surface coating: composite coating or fiber composite coating

Surface roughness: Ra0.8um-3.2um

Surface hardness: Shore D85, or fiber material surface hardness Barcol 55

Composite coating thickness: 0.3mm

Speed: linear speed 400m/min, or can be designed to >600r/min

Surface exhaust design: smooth surface

Application of Carbon fiber guide roller:

Nonwoven Farbic Carding & Lapping machine , Film

Except cylinder, we can also offer Hot Calender Roller, Embossing Calender Roller,Carbon fiber guide roller,Doffer roller etc for spunlace,spubond, meltblown nonwoven farbic.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Huatao Group Limited

- *Message:

-

Submit

Main Product:

Industrial Gearboxes,

Gear Reducers,

Electric Motor ,

Roller for Plastic Film & Sheet,

Bearings,

Gear motors

You May Also Like