Sn Salt Electrolytic Coloring Additive

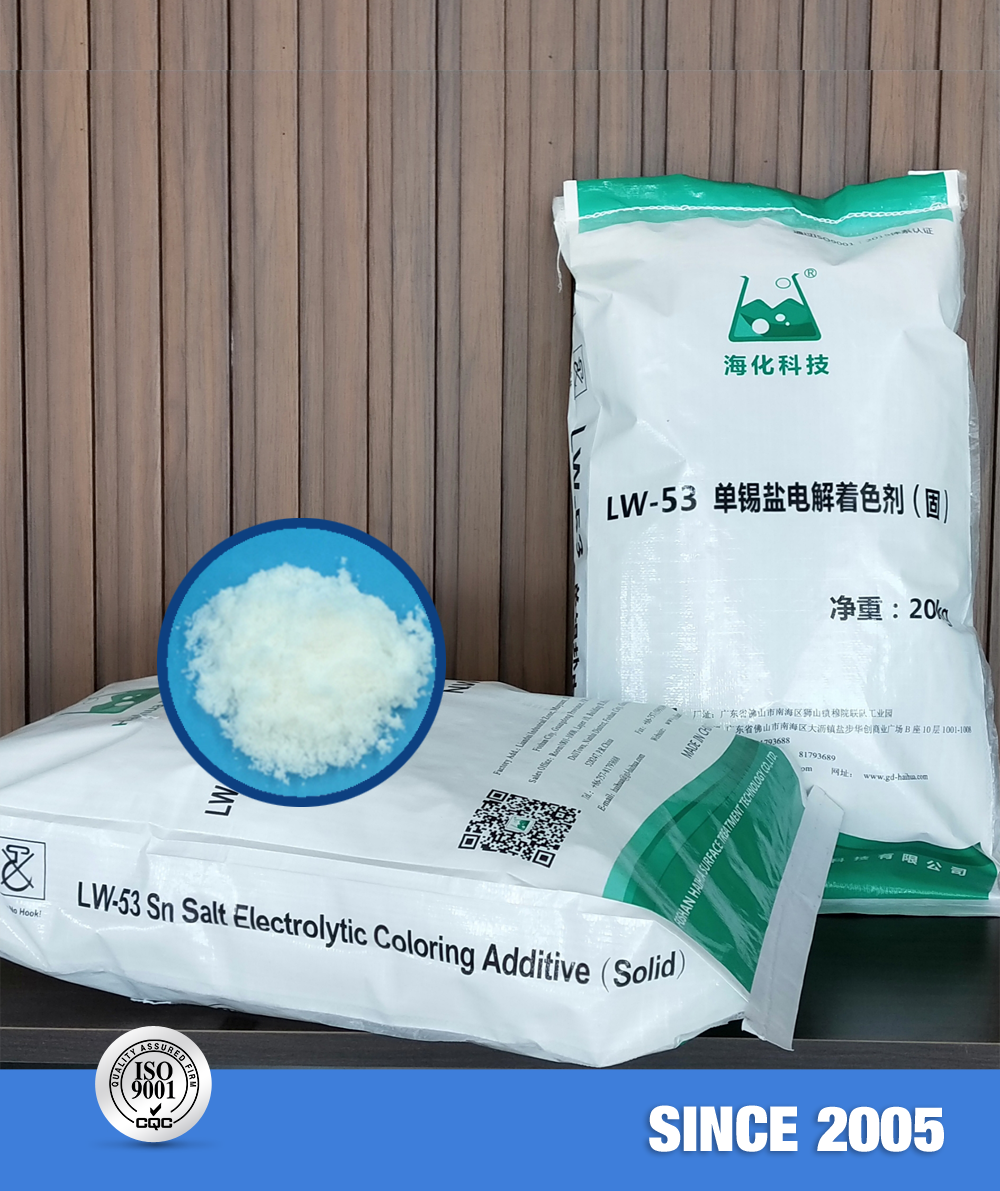

2 month agoLW-53 Sn Salt Electrolytic Coloring Additive, also known as Sn-Salt Electrolytic Coloring Agent and Salt Electrolytic Coloring Additive, is off-white to gray-brown crystals, playing a crucial role in the coloring of aluminum profiles after oxidation. In the Aluminium Anodizing Process, this additive proves to have good comprehensive performance, which is highly valued in the industry.

The stability of the bath liquid is a key factor. In actual production, the stability of the bath liquid is directly linked to the continuity of production and the consistency of product quality. The bath liquid formed by LW-53 Sn Salt Electrolytic Coloring Additive can maintain the relative stability of its chemical composition and physical properties during long-term use. This stability is essential for ensuring the quality of the final anodized products, whether they are aiming for a Gold Anodized finish or other color effects.

When it comes to coloring uniformity, during the electrolytic coloring stage, when the aluminum profile is immersed in the bath liquid containing this additive, the colorant can be evenly distributed on the surface of the aluminum profile under the action of the electric field. It then fully reacts with the oxide film to form a coating with uniform color. This is particularly important for achieving a high-quality appearance in anodized products, and LW-53, as an Anodizing Agent, plays a vital role in this process.

The good reproducibility of Sn-Salt Electrolytic Coloring Agent provides a strong guarantee for the large-scale production and brand promotion of enterprises. It enables enterprises to stably provide high-quality and uniform-color aluminum profile products to the market. This consistency is also beneficial for subsequent processes such as Cleaning Anodized Aluminum, as the quality and uniformity of the anodized surface make the cleaning process more predictable and efficient.

LW-53, as an Anodizing Agent, is easily soluble in water. This characteristic greatly facilitates production operations and enables the colorant to be quickly dispersed during the preparation of the tank solution, without the need for complex stirring equipment or long dissolution time, significantly improving production efficiency. Whether the final product is going to be a Gold Anodized item or not, this solubility feature helps streamline the Aluminium Anodizing Process.

Moreover, LW-53 has a stable performance. Whether in short-term production operations or in long-term storage, its chemical and physical properties will not change significantly. This stability allows the tank solution to be used for a long time, reducing product quality problems caused by changes in colorant performance, and also ensures that the anodized products, including those that might need subsequent Cleaning Anodized Aluminum steps, maintain a high standard of quality.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- FOSHAN HAIHUA SURFACE TREATMENT TECHNOLOGY CO., LTD.

- *Message:

-

Submit

Main Product:

aluminum cleaner,

aluminum brightener,

neutralizing agent,

passivation agent ,

aluminum paint stripper,

aluminum etchant

You May Also Like