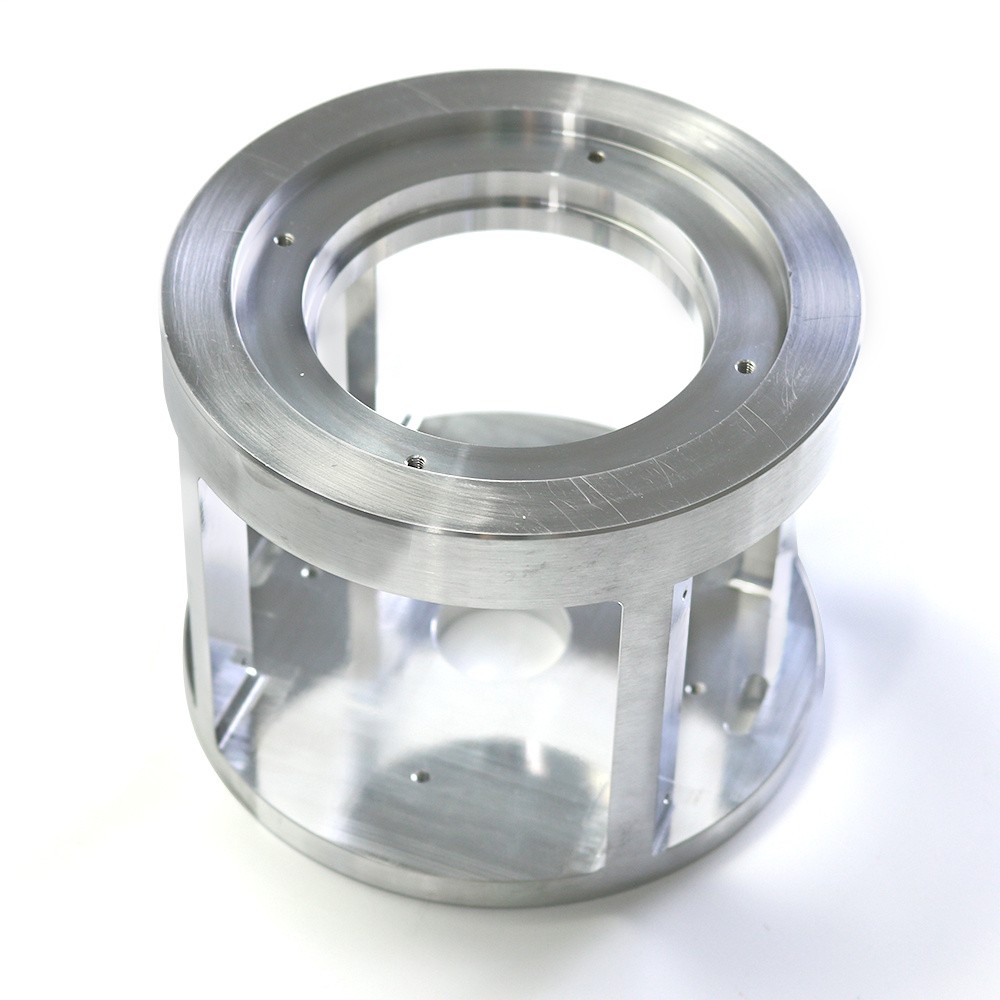

5 Axis Precision Custom CNC Produce OEM Milling Turned Metal Spare Machining Stainless Steel Service Aluminum Manufacturing Part1

3 year ago

The process involves feeding a design or model into a computer system of a CNC machine tool, which then guides the cutting tool to shape the material to specifications. CNC machine tools can perform a range of operations according to the requirements of the part, including milling, turning, drilling and grinding.

Stainless steel and aluminum are commonly used materials in CNC machining because of their durability, strength and corrosion resistance. They are also lightweight, perfect for applications where weight needs to be taken into account.

OEM milled metal spares produced through CNC machining are available for a variety of industries, including aerospace, automotive, medical and electronics. They can be customized to meet specific requirements and tolerances, ensuring a finished product of high quality and precision.

Overall, 5-axis precision custom CNC machining is a universal and efficient process for producing high quality metal parts, making it an excellent choice for Oems seeking custom metal parts manufacturing services.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Yuheng Precision Machinery Co., Ltd.

- *Message:

-

Submit

Main Product:

CNC Machining Service ,

CNC Milling Service,

CNC Turning Service,

Sheet Metal Fabrication,

Custom Screws,

Custom Nuts

You May Also Like