4 COLORS FLEXO CARTON MAKING MACHINE 2

10 month ago

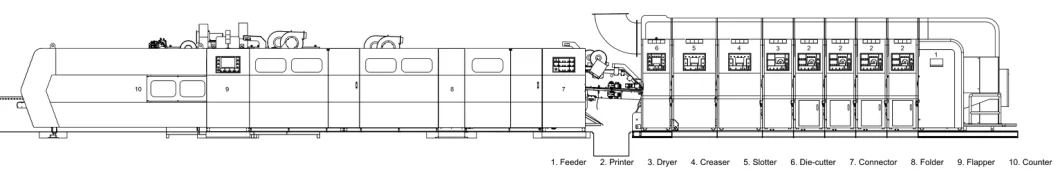

High Speed Flexo Printer Slotter Large Size Vacuum Transfer Carton Printing Die-Cutting Machine(Optional: prefeeder, bundling machine, stitching machine)

All units are motorized for opening and closing , with warning alarm system to ensure safety.

Independent computer (PLC) control is able to store different orders, enable quick order change.

The gaps between rolls are motorized with PLC control.

| Model | T-GC618 | T-GC920 | T-GC924 | T-GC1224 | T-GC1228 | T-GC1428 | T-GC1628 | T-GC1632 | T-GC1636 |

| Max. Speed (pcs/min) | 350 | 300 | 300 | 250 | 230 | 220 | 180 | 180 | 160 |

| Max. Feeding Size (mm) | 600×1800 | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2800 | 1600×2800 | 1600×3200 | 1600×3600 |

| Min. Feeding Size(mm) | 200×435 | 270×600 | 270×600 | 320×600 | 320×600 | 365×600 | 450×600 | 450×600 | 450×600 |

| Skip Feeding(mm) | 800×1800 | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 | 1700×2800 | 1900×2800 | 1900×3200 | 1900×3600 |

| Max. Printing Size (mm) | 600×1760 | 900×1960 | 900×2360 | 1200×2360 | 1200×2760 | 1400×2760 | 1600×2760 | 1600×3160 | 1600×3560 |

| Min. Slotting(L:mm) | 180×55× 180×55 | 240×65× 240×65 | 240×65× 240×65 | 260×65× 260×65 | 260×65× 260×65 | 260×65× 260×65 | 260×65× 260×65 | 260×65× 260×65 | 260×65× 260×65 |

| Min. Slotting (R: mm) | 110×110× 110×110 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 | 130×130× 130×130 |

| Max. Slotting Depth (mm) | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 400 | 400 |

Feeder Unit

2,Lead Edge Feeder with motorized feeding stroke adjust and reduce the pull roll pressure.

3,Original imported SUN Lead Edge Feeder to promise long - term feeding precision and stability.

4,Several row brushes and anti-static system to keep the paperboard clean before coming into printer unit, printing quality

promised.

5,Main motor is protected from start-up when units are not fully closed and locked.

Printer Unit

Optional function (Dryer)

Rotary Die-cutter Unit (Servo Drive Optional)

2,Anvil cylinder speed compensation achieved by adopting independent motor , the compensation scope is ±3.5mm.

3,Anvil cover trimming system to keep surface flat and smooth.

Vibrator&Auto Stacker

2, Vibrating belts adopting wrinkled imported belts, which controlled by independent speed motor

3, Cleaning section back-end adopts air blower and brush devices

4, Air compressed sheet catching arm

5, Tension of the transfer belt at the connection arm can be adjusted individually

Q1. Are you manufacturer?

A: Yes. We are manufacturing factory.

Q2. Where is your factory located?

A:Our factory is located in Hegui Industrial Park, Lishui, Nanhai District, Foshan City, Guangdong Province, China.

Q3. What kinds of products do you supply?

A: We provide one-stop solutions for corrugator factories all over the world. All kinds of machine spare parts & consumables for corrugator factories.

Q4. How about your service?

A:.A promptly reply in 12 hours, also contact by email, wechat, whatsapp, etc.

Free usage training before shipping, and professional package to keep the machine fasten during shipment

Q5. Where were your products exported before?

A:Vietnam, Thailand, Myanmar, Philippine, Malaysia, Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia,

Lithuania, Mexico, Brazil, Argentina, Venezuela, Honduras, Korea and etc

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like