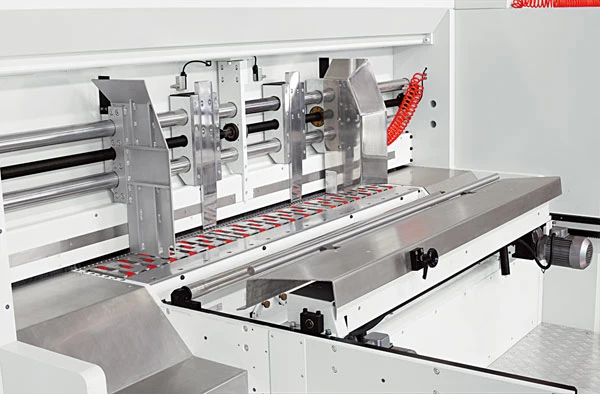

printer slotter

10 month ago

Features in Performance

1. Advanced scientific design concept, European CE certification, independent computer operating table

2. Gap adjustment and phase adjustment are computer controlled

3. Main gear is made of high quality steel, imported from Taiwan

4. All electrical, electronic and pneumatic components adopt European standards

5. Suitable for dot printing on coated paper, or cardboard printing

6. Can be used with stacking machines or printing glue box machines

|

Item

|

NT0920A

|

NT0925A

|

NT1225A

|

NT1228A

|

NT1628A

|

NT1632A

|

|

Maximum equipment speed (sheet/min)

|

300

|

280

|

250

|

230

|

180

|

160

|

|

Maximum feed size (mm)

|

900×2000

|

900×2500

|

1200×2500

|

1200×2800

|

1600×2800

|

1600×3200

|

|

Minimum feed size (mm)

|

300×600

|

300×600

|

350×600

|

350×600

|

450×600

|

450×600

|

|

Sheet feeding (mm)

|

1200×2000

|

1200×2500

|

1500×2500

|

1500×2800

|

2000×2800

|

2000×3200

|

|

Printing area (mm)

|

900×1960

|

900×2460

|

1200×2460

|

1200×2760

|

1600×2760

|

1600×3160

|

|

Standard printing thickness (mm)

|

7.2

|

7.2

|

7.2

|

7.2

|

7.2

|

7.2

|

|

Min Slotting Clearance

Forward knife(mm) |

130×130×

130×130

|

130×130×

130×130

|

130×130×

130×130

|

130×130×

130×130

|

130×130×

130×130

|

130×130×

130×130

|

2. Adopting the leading edge paper feed from the United States to increase the suction flow, the paper feed is more stable and accurate.

3. Variable frequency control of vacuum airflow and pressure to match cardboard size

4. Adjustable paper-feeding stroke to reduce the pressure of the paper-pulling rubber roller

5. Efficient dust removal device, double-row brush and fan to remove paper dust on cardboard surface

6. Vacuum feeding, six rows of brushes, equipped with electrostatic device, better dust removal effect (optional)

2. Choice of doctor blade or roller-to-roll ink supply system

3. Automatic switching of cleaning devices, making ink recycling or cleaning easier and faster

4. Anti-leakage, ink rejection system device

5. Automatic reset system after printing plate cleaning

6. Ink-saving system, each unit can save 0.4-0.5 kg of ink when changing color or cleaning ink (for roller-suction diaphragm pump ink supply system)

7. Each group of printing units can be equipped with hot air device (optional)

2. Infrared or ultraviolet tube can be controlled in sections according to the width of the cardboard, saving energy and equipped with a fire prevention device

2. Using precise linear guide system, precise displacement, smooth slotting

3. Pre-pressing process structure, cardboard is not easy to break

4. The upper tool holder and the lower tool holder are linked by a transmission shaft, which keeps the upper and lower knives aligned when moving to extend the tool life.

5. Flexible corner cutter structure, can cut three or five layers of cardboard without adjustment, easy to operate

2, Adopt independent motor drive, rubber pad compensation range ± 3mm

3, Cutting and smoothing structure of rubber pad rollers to keep the surface of rubber pads flat

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers ,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter

You May Also Like