price off! EPS PS foam thermocol plate take away food container making machine/disposable box bowl egg tray dish production line1

3 year ago

price off! EPS PS foam thermocol plate take away food container making machine/disposable box bowl egg tray dish production line

PS/PSP foam disposable fast food containers/box/plate/bowl / dish /

absorbent tray / egg tray / bowl / false ceiling tiles / cup production line

Fast food box production line mainly includes three parts:

1. PS Foam Sheet Extrusion Line

2. Automatic Vacuum Forming integrated Cutting stacking Machine

3. Crusher and Recycling Machine

This line is the whole production line, which can form lunch box from raw material. This is the recycle. The work flow is as follows: raw material---(PS foam sheet extrusion line)---foam sheet---(lunch box forming machine and cutting machine)---lunch box---(plastic recycle machine)---plastic granulators( this part can be used as raw material)----foam sheet.

1. PS Foam Sheet Extrusion Line

PS Foam Sheet Extrusion Line:

PS foam sheet machine adopts Gentian type double-stage series high foam technology. The raw material is general polystyrene granule. In the extruding process, vesicant is injected at high pressure. After extruding, foaming cooling, shaping and hauling off, it is winding to finished PS foam sheet rolls .After vacuum forming system, the finished PS foaming sheet can be made into variety of packaging vessels such as fast food box, aquatic plate, supermarket tray, cake tray ,KT board, instant noodle bowl, foam tray etc. It is widely used in the packing of food, fruit advertising ,industrial products and so on. This equipment adopts high speed non-stop hydraulic filter changer and PLC controller.

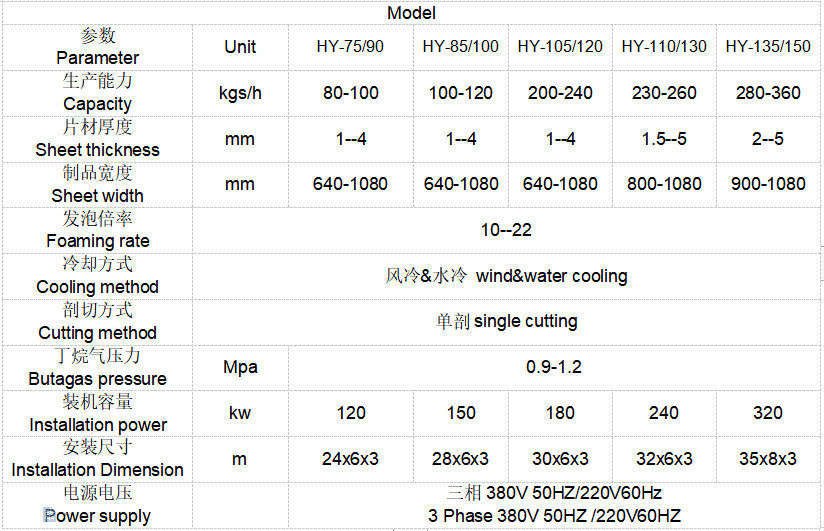

PS foam sheet extrusion machine parameter :

finished products: PS foam sheet rolls

2.:foam food container automatic vacuum forming machine

Automatic Vacuum Forming and Cutting Machine with Mechanical Arm

Max forming area: 1100mmx1400mm

Max forming depth: 50mm

Forming mode: Vacuum forming, press forming, mold forming, comprehensive forming

Forming pressure: 60t (adjustable)

The production efficiency:3 seconds/mold

Dimension:12mx2mx2.6m

Weight :28T

this machine can produce normal foam food containers and absorbent tray

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

The machine is plastic sheet forming equipment in one step with following process: transporting sheet, heating, forming, cutting, stacking and winding waste edge.

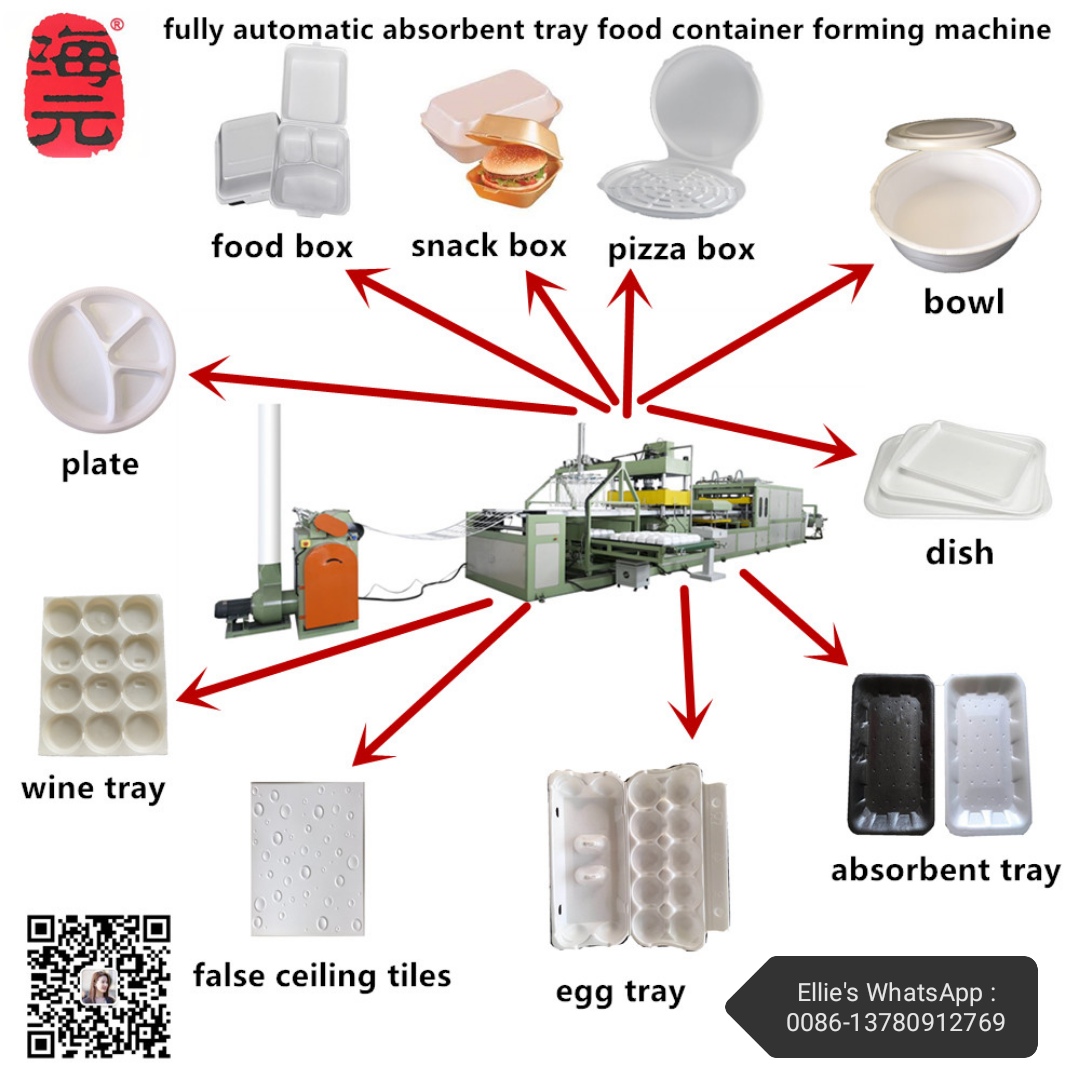

Applications

-- Disposable material for lunch box, food container , dish , egg tray , absorbent tray , false ceiling tiles , bowl, tray, plate etc …

-- Internal cushioning material for food, fruits and cosmetics

finished products:

3.:recycling machine

Recycling Machine

This machine is mainly used to recycle the high foam polystyrene and high foam polyethylene products. It is the ideal equipment to recycle the waste materials. This equipment features compact structure and easy operation. The high foam plastic can be directly used to make granulation without comminuting. At present ,it is the ideal energy-saving equipment.

Contact us:

welcome to scan this QR code to add Ellie's WeChat

Contact Ellie by WhatsApp :

008613780912769

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- haiyuanmachinery

- *Message:

-

Submit

Main Product:

Foam Food Box Machine,

Foam Plate Making Machine ,

PS Foam Sheet Extrusion Line,

PS Foam Absorbent Tray Making Machine,

PS Foam Food Container Production Line,

Thermocol Plate Making Machine

You May Also Like