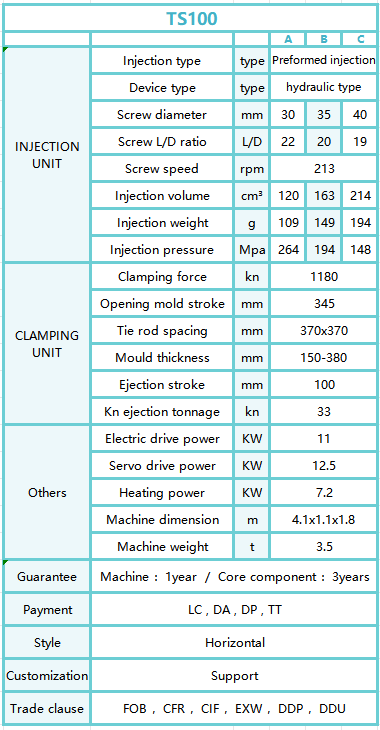

TS100 plastic spoon plastic forming

6 month agoEnergy Saving Hydraulic Unit of TIANSU Plastic Molding Machines

1. Significance of the Hydraulic Unit

In the world of plastic molding, the hydraulic unit of our plastic injection molding machine is a cornerstone of efficient operation. It is a complex yet well designed system that plastic moulding machine manufacturers rely on for high quality machine injection moulding.

2. Structural Components

Components Working in Harmony

The hydraulic unit is composed of multiple essential parts. The servo precision energy saving power system stands out as a key component. It is responsible for optimizing the power output based on the load of the plastic molding machine. The oil tank, being visual and detachable, serves as a reservoir for the hydraulic fluid and provides easy access for inspection. The self sealing magnetic oil suction filter, European hydraulic hose, DIN standard spherical joint, and valve plate with G thread sealing plug are also integral parts of this system.

3. Servo Precision Energy Saving Power System

Energy Efficiency Redefined

The servo precision energy saving power system is a technological marvel. It can sense the load on the plastic injection molding machine and adjust its power output accordingly. This dynamic adjustment leads to substantial energy savings. For plastic moulding machine manufacturers, this means a significant reduction in electricity costs. By consuming 20% 80% less electricity compared to traditional machines, it not only improves the bottom line but also makes the production process more sustainable.

4. Environmental Friendly Attributes

Quiet and Clean Operation

Our hydraulic unit is engineered to be environmentally friendly. It operates with low noise, which is beneficial for the workplace environment. The use of European hydraulic hose, DIN standard spherical joint, and valve plate with G thread sealing plug helps in preventing oil leakage. The DIN standard spherical joint is designed to provide a tight and reliable connection in the hydraulic circuit. The G thread sealing plug on the valve plate ensures that the hydraulic oil remains contained, reducing the risk of oil pollution. These features make our plastic injection molding machine an ideal choice for those who prioritize environmental protection.

5. Maintenance Friendly Design for Maximum Uptime

Simplifying Maintenance

The design of our hydraulic unit takes maintenance into account. The visual and detachable oil tank allows for quick and easy inspection of the oil. The self sealing magnetic oil suction filter is a great asset. It can capture metal contaminants in the oil, protecting the hydraulic system from damage. Its self sealing property ensures that oil does not leak during removal. The well thought out pipe joint layout also simplifies the maintenance process. All these features work together to reduce the downtime of the plastic injection molding machine, enabling plastic moulding machine manufacturers to keep their production running smoothly.

These are the products our company is most proud of producing: injection mold, Servo hydraulic small injection molding machine, injection molding machine mold, plastic injection machine.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Ningbo Outai Plastic Machinery Technology Co.,Ltd

- *Message:

-

Submit

Main Product:

Injection molding machine,

Auxiliary machine,

injection machine Nozzle ,

Drive Belt and Pulley,

injection machine Electric Motor,

injection Molds

You May Also Like