Blanking zone

4 year ago

The storage environment of Copper Terminals is specified in the general and detailed specifications for most Copper Lugs.

For example, SJ331 stipulated that the environmental conditions of semiconductor integrated circuit storage are: -10℃ ~ +40℃, RH≤80%; The US Military standard for semiconductor integrated circuit storage environment temperature range from -65℃ to +150℃. However, these standards only specify the storage environment that is not allowed to exceed the range, not the optimal storage environment for Copper Tube Terminals. GB4798.1 stipulates that the environment level of the warehouse storing precision instruments and wiring terminals is the highest, with environmental conditions ranging from 20℃ to 25℃. RH ranges from 20% to 70%; The pressure ranges from 70kPa to 106kPa. QJ2222A defines two conditions: general storage environment and special storage environment. The general storage environment standard specifies that terminals should be stored in a clean, ventilated place free of corrosive gases and controlled by temperature and relative humidity, as shown in Table 1.

The environmental conditions of class ⅰ, ⅱ and ⅲ are different. Class ⅰ, generally do not need to adjust the temperature and humidity; Class ⅱ, need to adjust the temperature and humidity in individual seasons; Class ⅲ, the temperature and humidity need to be adjusted to meet the requirements.

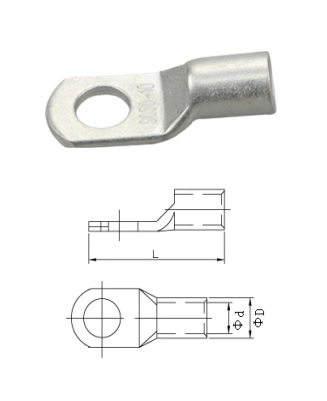

SC Cold-pressed Terminal are suitable for the connection of copper conductors (section 1.5-630mm2) in power cable with electronic equipment, they are made of higher 99.99 % pure copper tube T2 and coated with tin. Working temperature -55oC-150oC.

The company has more than 95% of the full automatic production lines, nissan 200 tons, production capacity continues to adjust and expand, to meet the challenge of the market at any time.Through the European CE safety certification, American UL safety certification, the company has a SC Japan JIS standard, the German DIN standards, AWG American standards, etc.

Companies always adhere to: quality first, service first, from raw materials into the factory inspection, process inspection to every working procedure, outbound packaging cengcengbaguan .

Company has own copper pipe, copper strip, copper platoon of raw material processing factory, with strong competitive advantage price on equal quality to every guest get the maximum benefits.

Material: High Conductivity Copper

Purity: >99.9%

Coating:shining tin plating or dark tin plating

| ITEM NO | DIMENSIONS | |||

| φE | ΦD | Φd | L | |

| SC(JGK)-1.5 | φ4.2,φ5.2 | 3.5 | 2.3 | 18.0 |

| SC(JGK)-2.5 | φ4.2,φ5.2,φ6.2 | 4.0 | 2.8 | 19.0 |

| SC(JGK)-4 | φ5.2,φ6.2 | 4.8 | 3.1 | 20.0 |

| SC(JGK)-6 | φ5.2,φ6.2,φ8.2 | 5.5 | 3.8 | 23.0 |

| SC(JGK)-10 | φ6.2,φ8.2 | 6.8 | 4.8 | 24.5 |

| SC(JGK)-16 | φ6.2,φ8.2,φ10.5 | 7.5 | 5.5 | 29.5 |

| SC(JGK)-25 | φ6.2,φ8.2,φ10.5 | 9.0 | 7.0 | 32.5 |

| SC(JGK)-35 | φ6.2,φ8.2,φ10.5,φ12.5 | 10.5 | 8.3 | 37.5 |

| SC(JGK)-50 | φ8.2,φ10.5,φ12.5 | 12.5 | 9.8 | 44.5 |

| SC(JGK)-70 | φ8.2,φ10.5,φ12.5 | 14.5 | 11.5 | 48.0 |

| SC(JGK)-95 | φ10.5,φ12.5 | 17.5 | 13.8 | 54.0 |

| SC(JGK)-120 | φ12.5,φ16.5 | 19.5 | 15.5 | 61.0 |

| SC(JGK)-150 | φ12.5,φ16.5 | 21.0 | 16.5 | 68.0 |

| SC(JGK)-185 | φ16.5 | 23.5 | 18.8 | 76.0 |

| SC(JGK)-240 | φ16.5 | 26.0 | 21.0 | 88.5 |

| SC(JGK)-300 | φ16.5,φ20.5 | 30.0 | 24.0 | 99.0 |

| SC(JGK)-400 | φ16.5,φ20.5 | 34.0 | 27.0 | 110.5 |

| SC(JGK)-500 | φ16.5,φ20.5 | 38.0 | 30.0 | 121.0 |

| SC(JGK)-630 | φ20.5 | 45.0 | 35.0 | 135.5 |

| SC(JGK)-800 | φ22.5 | 50.0 | 39.0 | 170.0 |

| SC(JGK)-1000 | φ22.5 | 56.0 | 44.0 | 200.0 |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Taixing Longyi Terminals Co.,Ltd.

- *Message:

-

Submit

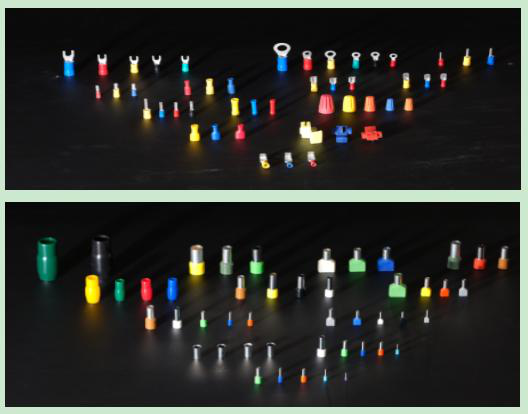

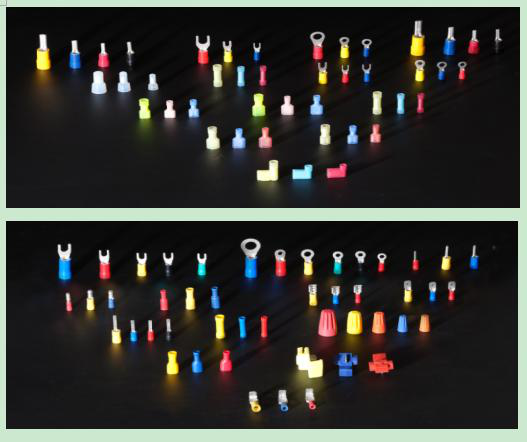

Main Product:

Copper Lugs,

Copper Terminals,

Insulated Terminals,

Copper Tube Terminals,

Cold-pressed Terminal ,

Non-insulated Tubular Lugs Terminals

You May Also Like