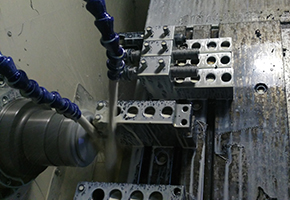

Auto turning aluminium parts

5 year ago

Custom Turned Aluminium Parts

Lathe machining is often used to turned aluminium parts. The density of turned aluminium parts is greatly reduced compared with the density of iron and steel parts, and the difficulty of aluminium custom fabrications is low. turned aluminium parts have strong plasticity, stable product quality, and greatly shorten the machining time of parts by lathe.

We provide cnc machining turning prarts that meet the performance, quality, reliability, and safety requirements of our customers.And the design of reasonable detection fixture to ensure more efficient testing.

1 Machining Processes

- CNC Milling

- CNC Turning

- CAM Programming

- sheet metal fabrication

- Grinding

- Cutting

- Thread Turning / Milling threading

- Tapping

- Drilling

-

Knurling

2 Material ( Machining Metal )

- Aluminum 6061, 6061-T6,6063,7075,5052,2024,2017.

- Copper,Brass,Bronze,Phosphor Bronze.( C10100,C10200,C11000,C12200,C26000,C27000,C28000,C33000,C220,C510,C630 )

- Stainless Steel 303,304,316 ( 1.4305,1.4301 )

-

Steel Ordinary carbon structural Steel,Quality carbon structural steel,.cast steel,Iron.

(Q195,Q215,Q235,Q255,10#,20#,35#,45#,718H,S136,SKD11 ) - Titanium

Machining Plastic

- Delrin ( Black,White,Blue,Red,Yellow)

- Nylon

- Neoflon

- PTFE,Teflon,

- Ultem

- Torlon

- Peek

- PMMA

- PC,

- PAI,PPS,PA,PVDF,POM,PA,PET,PEI .

- CNC Milling Parts ( Max ) : Length 1030mm,Width 800mm, Height 750mm.

- CNC Turning Parts (Max ): Diamter 680mm,Length 750mm.The size of the above parts are machined in the workshop.

4 Tolerance:0.01mm. Minority size:0.005mm. The measuring instrument can measure the dimension precision:0.001mm.

5 Secondary Services of Machining Parts

- Anodize,Anodize color ( Black,Clear, Red, Blue,Yellow,Etc. ) , Hard Anodize,Hard Anodize Teflon. ( Machining Aluminum )

- Electroless Nickel ( Machining Aluminum parts, Machining Stainless Steel parts, Machining Steel parts,Machining Copper parts )

-

Plating Zinc Color ( Machining Steel parts )

- Passivation ( Machining Stainless Steel parts )

- Sand Blasting ( Machining Aluminum parts )

- Brushed ( Machining Aluminum parts , Machining Stainless Steel parts )

- Bluing and Blackening ( Machining Steel parts )

- Trivalent Chromium Process ( Machining Aluminum parts )

- Welding,brazing and soldering.

- Centerless Grinding and Burnishing

- Assemble

6 Equipment Capabilities

- CNC Machinig Center, 3 Axis ,4 Axis.

- CNC Lathe, Lathe,CNC Turning Centers, Horizontal 8/12-position hydraulic turret.

- Milling Machine

- Grinding Machine

-

Drill Press

-

Tapping Center

-

Rotary Indexer

- Punch

7 Delivery cycle ( CNC Machining and CNC Turning )

- sample - The urgent machining service, the fastest 3 days to complete.

-

Small batch machining - Workers are on duty for 24 hours. There are 3 to 5 machining centers designed for Small batch machining.

-

Batch parts - 3~4 Weeks,Depending on the degree of difficulty of machining parts.

8 File formats

- X-T / STEP / STP / IGS / DWG AutoCAD / DXF and PDF

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Hong Kong RYH CO., LTD

- *Message:

-

Submit

Main Product:

CNC Machining,

CNC Machining Parts,

Machining,

CNC Milling,

CNC Turning ,

Machining Parts

You May Also Like